Nov . 15, 2024 03:10 Back to list

fiber glass net mesh manufacturers

The Rise of Fiberglass Net Mesh Manufacturers An Overview

In recent years, the demand for fiberglass net mesh products has surged as industries increasingly seek durable and lightweight materials for various applications

. Fiberglass net mesh is renowned for its strength, flexibility, and resistance to environmental factors, making it an ideal choice for construction, automotive, and even aerospace sectors.Fiberglass net mesh is made by weaving glass fibers into a strong, flexible fabric that can be coated with resins or other materials for added functionality. This mesh serves as a reinforcement in composite materials, providing structural integrity while minimizing weight. The benefits of using fiberglass net mesh are evident in the construction industry, where it is commonly used for reinforcing concrete, plaster, and asphalt. Its ability to distribute loads evenly helps reduce cracking and improves the longevity of structures.

The manufacturing of fiberglass net mesh involves several intricate processes. Manufacturers start with high-quality fiberglass strands, which are woven into a net-like structure. The mesh can then be coated with protective materials to enhance its durability against moisture and chemicals. High-standard production techniques are vital to ensure that the final product meets the rigorous specifications required by various industries.

fiber glass net mesh manufacturers

As the global market for fiberglass products continues to grow, so does competition among manufacturers. Companies are now focusing on innovation and sustainability, working to develop environmentally friendly production processes while enhancing the performance characteristics of fiberglass net mesh. This shift not only caters to increasing regulations on environmental impact but also appeals to a growing consumer base that prioritizes sustainable choices.

In addition to traditional applications, fiberglass net mesh is finding new uses in emerging sectors. For instance, the rise of renewable energy technologies has created a demand for lightweight and resilient materials for wind turbine blades and solar panels. Manufacturers are adapting their products to meet these innovative needs, proving the versatility of fiberglass net mesh beyond conventional sectors.

Moreover, the global supply chain for fiberglass net mesh is becoming increasingly interconnected. Manufacturers from various regions are collaborating and sharing expertise, leading to improved product quality and competitive pricing. This globalization has allowed small and medium enterprises to tap into international markets, broadening their reach and expanding their customer base.

In conclusion, fiberglass net mesh manufacturers play a crucial role in delivering high-performance materials that empower numerous industries. Through continuous innovation and a commitment to sustainability, these manufacturers are well-positioned to meet the evolving demands of the market, ensuring that fiberglass net mesh remains a vital component of modern engineering and construction. As the industry advances, the future of fiberglass net mesh looks promising, with endless possibilities for development and application.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

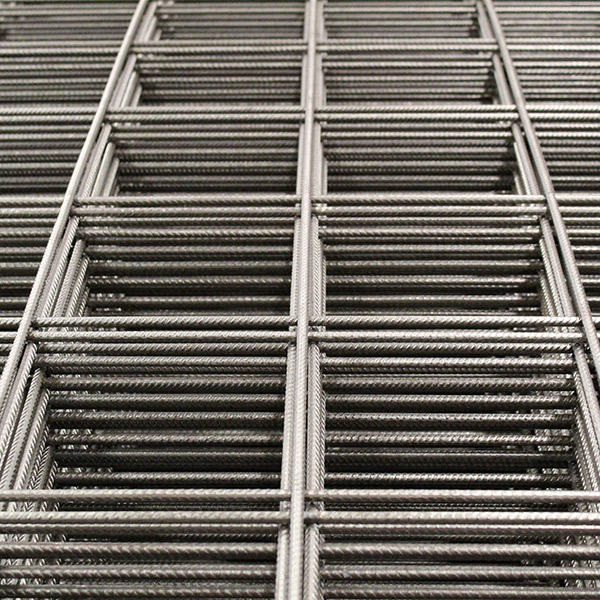

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025