Dec . 01, 2024 14:41 Back to list

fiber glass net mesh factory

The Importance of Fiberglass Net Mesh in Modern Industries

In today’s industrial landscape, the demand for high-performance materials is ever-increasing, and fiberglass net mesh has emerged as a critical component across various sectors. This innovative material, produced in specialized factories, offers durability, flexibility, and resistance to environmental factors, making it ideal for a wide range of applications.

Fiberglass net mesh, also known as fiberglass mesh or fiberglass netting, is crafted from woven strands of glass fibers. These fibers are processed and coated to enhance their strength and resilience. The production process typically involves weaving the fibers into a mesh fabric, which can then be treated with various coatings to improve its performance characteristics. The result is a lightweight, strong material that is resistant to corrosion and degradation, making it suitable for both indoor and outdoor applications.

Key Applications of Fiberglass Net Mesh

One of the primary applications of fiberglass net mesh is in the construction industry. It is commonly used as reinforcement in plaster, concrete, and stucco systems. By incorporating fiberglass mesh into these materials, buildings gain added strength and resistance to cracking, a crucial feature in regions prone to seismic activity or fluctuating weather conditions. This reinforcement not only enhances structural integrity but also prolongs the lifespan of the materials used in construction.

In addition to its use in construction, fiberglass net mesh is also widely utilized in the automotive and aerospace sectors. The lightweight nature of fiberglass contributes to overall fuel efficiency without compromising safety or performance. Manufacturers often incorporate fiberglass mesh in composite materials for car bodies, interiors, and even aircraft components, where reducing weight is a primary concern. This versatility underscores the material’s importance in modern manufacturing processes.

Another notable application is in environmental protection and agriculture. Fiberglass net mesh is used in erosion control systems and as protective screens for crops. Its durability allows it to withstand harsh environmental conditions, offering long-lasting solutions for soil stabilization and pest protection, thereby enhancing agricultural productivity.

fiber glass net mesh factory

Manufacturing Process and Quality Control

The production of fiberglass net mesh involves several crucial steps to ensure high quality and performance standards. Factories specializing in fiberglass mesh begin by selecting premium raw materials, primarily high-strength glass fibers. These fibers are then woven together in specific patterns, which can vary based on the intended application of the finished product.

Quality control is a fundamental aspect of the manufacturing process. Factories implement rigorous testing protocols to assess the tensile strength, flexibility, and resistance to various environmental factors of the fiberglass mesh. This ensures that the final product meets industry standards and customer specifications. Moreover, many factories adhere to international quality certifications, further solidifying their reputations in the competitive market.

Environmental Considerations

As the world becomes increasingly aware of the need for sustainable practices, fiberglass net mesh factories are also taking steps to minimize their environmental impact. Many manufacturers are adopting greener production methods, including recycling waste materials and utilizing eco-friendly coatings. The inherent durability of fiberglass mesh already contributes to sustainability, as its long lifespan reduces the need for frequent replacements.

Conclusion

In conclusion, fiberglass net mesh is a versatile and essential material in numerous industries, from construction to agriculture and beyond. Its strength, durability, and resistance to environmental hazards make it a preferred choice for manufacturers looking to enhance their products' performance. As technology advances and industries evolve, the role of fiberglass net mesh will continue to expand, driven by its ability to meet the demands of modern applications while supporting sustainable practices. Factories producing fiberglass mesh are at the forefront of this innovation, contributing to the development of safer, more efficient products that shape our infrastructure and daily lives.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

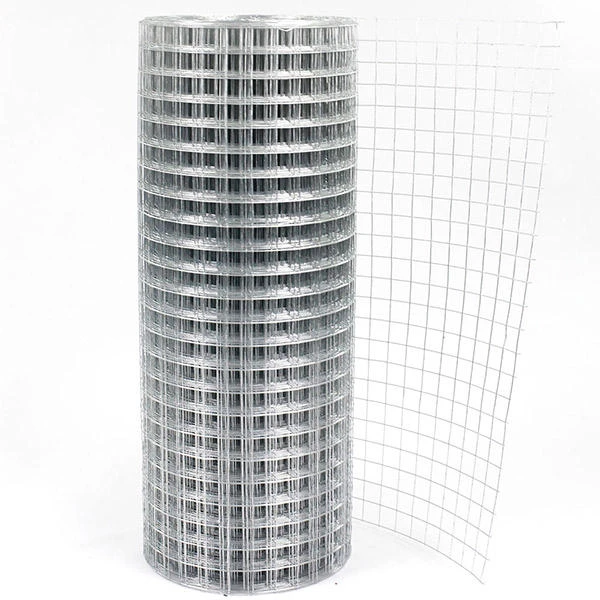

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025