Nov . 22, 2024 17:22 Back to list

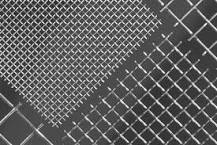

fiberglass mesh manufacturers

The Role of Fiberglass Mesh Manufacturers in Modern Construction

In the world of construction and renovation, the importance of materials cannot be overstated. One such material that has gained significant recognition is fiberglass mesh. This composite material, made from woven glass fibers, offers remarkable strength and durability, making it ideal for various applications, particularly in the construction industry. As the demand for fiberglass mesh continues to rise, the role of fiberglass mesh manufacturers becomes increasingly vital.

Understanding Fiberglass Mesh

Fiberglass mesh is a versatile product commonly used for reinforcing construction materials, enhancing the strength and longevity of structures. This mesh is made from strands of glass fibers that are woven together into a net-like fabric. Its primary attributes include resistance to chemicals, high tensile strength, and excellent dimensional stability. These properties make it especially suitable for use in plastering, roofing, and wall reinforcement.

One of the most notable benefits of fiberglass mesh is its lightweight nature combined with its robustness. Unlike traditional metal reinforcing materials, fiberglass mesh does not corrode over time, making it more reliable for long-term use. It is especially beneficial for applications in areas that experience extreme weather conditions or for structures that must maintain integrity against seismic activities.

The Manufacturing Process

The production of fiberglass mesh involves several steps. First, raw materials are sourced, typically from natural silicates. These raw materials are then transformed into glass fibers through a process known as fiberization. The fibers are then woven into a specific mesh structure, which can be tailored according to the intended application. After weaving, the mesh usually undergoes treatments, such as coating or impregnation with resin, to enhance its performance characteristics.

Manufacturers often specialize in producing different types of fiberglass meshes to meet the diverse needs of their customers. Some meshes are designed for specific applications, such as insulation or soundproofing, while others may be intended for larger construction projects like bridges and roads.

The Importance of Quality Control

fiberglass mesh manufacturers

For fiberglass mesh manufacturers, quality control is paramount. The strength, flexibility, and durability of the final product depend significantly on the manufacturing processes and materials used. This is why leading manufacturers invest heavily in advanced technology and best practices to ensure their fiberglass mesh meets the highest industry standards.

Regular testing of flexural strength, tensile strength, and fire resistance is crucial in this regard. Compliance with international standards, such as ISO and ASTM, not only ensures product reliability but also builds trust with clients. Manufacturers who adhere to these standards often differentiate themselves in a competitive market.

Market Demand and Trends

The demand for fiberglass mesh is closely tied to the construction industry's growth. As urban development accelerates around the globe, the need for strong, durable materials able to withstand the strain of weight and natural disasters grows. Additionally, the trend toward sustainable construction practices has boosted fiberglass mesh's popularity, as it can be recycled and reused.

Moreover, the increasing use of lightweight building materials complements fiberglass mesh technology, providing added value by enhancing structural integrity without significantly increasing weight. Manufacturers are continually innovating to develop new mesh varieties that cater to evolving market needs, focusing on aspects like eco-friendliness and cost-effectiveness.

Future Prospects

Looking ahead, the future for fiberglass mesh manufacturers appears bright. With ongoing advancements in technology and materials science, manufacturers can expect to produce even higher-quality products that offer superior performance. Furthermore, as global construction projects ramp up, especially in developing countries, the requirement for reliable and efficient construction materials like fiberglass mesh will likely surge.

In conclusion, fiberglass mesh manufacturers play a critical role in shaping the future of construction and renovation practices. By producing high-quality, reliable, and cost-effective materials, they contribute significantly to building safer and more sustainable structures. As the industry continues to evolve, these manufacturers will remain at the forefront of innovation, meeting the ever-changing demands of the construction landscape.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025