Nov . 09, 2024 08:37 Back to list

F72 Reinforcing Mesh Manufacturer and Supplier for Construction Projects

The Importance of F72% Reinforcing Mesh in Construction An Overview of the Factory Production Process

In the world of construction, structural integrity is of paramount importance. To achieve the desired strength and durability in concrete structures, the use of reinforcing mesh has become an industry standard. Among the various types of reinforcing mesh available, F72% reinforcing mesh stands out for its unique properties and benefits. This article delves into the significance of F72% reinforcing mesh and provides an overview of its factory production process.

Understanding F72% Reinforcing Mesh

F72% reinforcing mesh is a high-quality wire mesh used to enhance the tensile strength of concrete structures. It is engineered from high-tensile steel, providing a robust framework that prevents cracking and deformation in concrete. The designation 'F72%' refers to the specific tensile strength rating, indicating that the mesh can withstand significant loads and stresses. This makes it particularly suitable for applications in heavy-duty construction projects such as highways, bridges, and industrial floors.

The Benefits of F72% Reinforcing Mesh

One of the primary advantages of F72% reinforcing mesh is its ability to distribute loads evenly across the concrete surface. This uniform load distribution minimizes the risk of localized failures, which can lead to structural collapse. Additionally, the mesh prevents shrinkage cracks that often occur as concrete cures. By incorporating F72% mesh into their designs, engineers can ensure longer-lasting, safer structures.

Moreover, the use of F72% reinforcing mesh can lead to cost savings in construction. By reducing the likelihood of structural failures and the need for repair, this type of mesh can lower maintenance costs over the lifecycle of the building. Furthermore, its lightweight nature ensures easier handling, reducing labor costs during installation.

f72 reinforcing mesh factory

Production Process of F72% Reinforcing Mesh

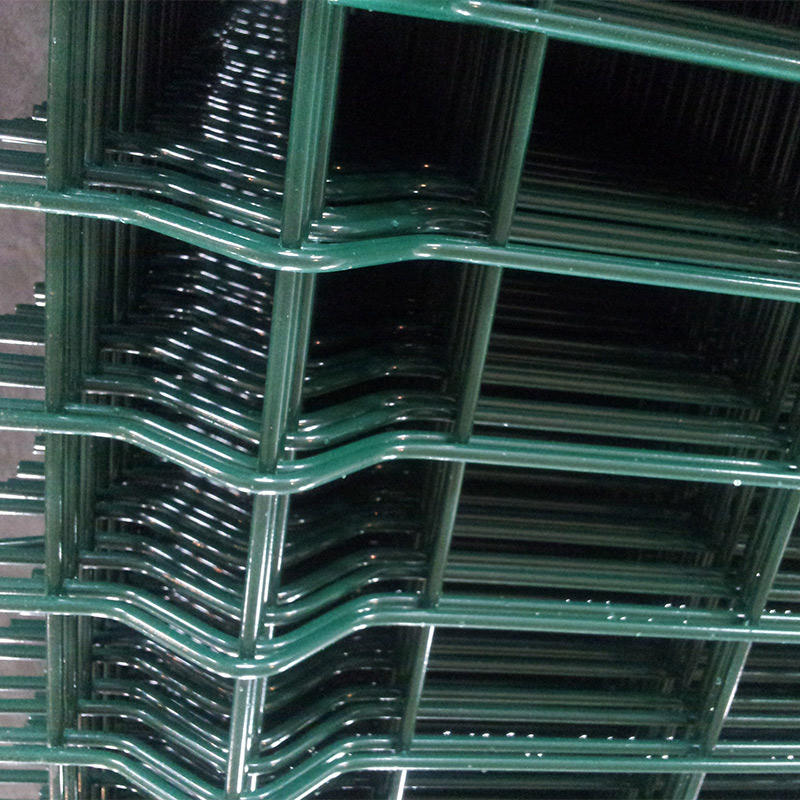

The production of F72% reinforcing mesh occurs in specialized factories equipped with advanced technology. The process begins with the selection of high-tensile steel wire, which is crucial to the performance of the final product. The steel is then fed into machines that cut and bend it into the required mesh shape and size.

After the wire has been cut and shaped, it is welded at intersections to form a grid pattern. This reinforcement structure is fundamental, as it ensures that the mesh can effectively carry loads. The welding process is carefully monitored to meet strict quality standards, as any weaknesses at the joints can compromise the integrity of the mesh.

Once the welding process is complete, the mesh undergoes a thorough quality inspection. This step is essential to identify any potential defects that could affect performance. The final product is then treated with protective coatings to enhance its resistance to corrosion, further increasing its longevity in challenging environments.

Conclusion

F72% reinforcing mesh is an indispensable component in modern construction, providing enhanced strength and durability to concrete structures. Its unique properties make it a preferred choice for engineers and contractors who prioritize safety and efficiency. Understanding the production process of F72% reinforcing mesh highlights the careful craftsmanship and quality control that goes into creating this vital construction material. As the construction industry continues to evolve, the role of F72% reinforcing mesh and other advanced materials will undoubtedly grow, contributing to the development of safer and more sustainable structures.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025