Nov . 06, 2024 00:05 Back to list

f72 reinforcing mesh factories

The Importance of F72% Reinforcing Mesh in Construction

The construction industry has long relied on various materials to ensure the strength and durability of structures. Among these materials, reinforcing mesh plays a crucial role in providing additional support to concrete and masonry structures. One of the essential types of reinforcing mesh is F72% reinforcing mesh, which has garnered attention for its unique properties and advantages.

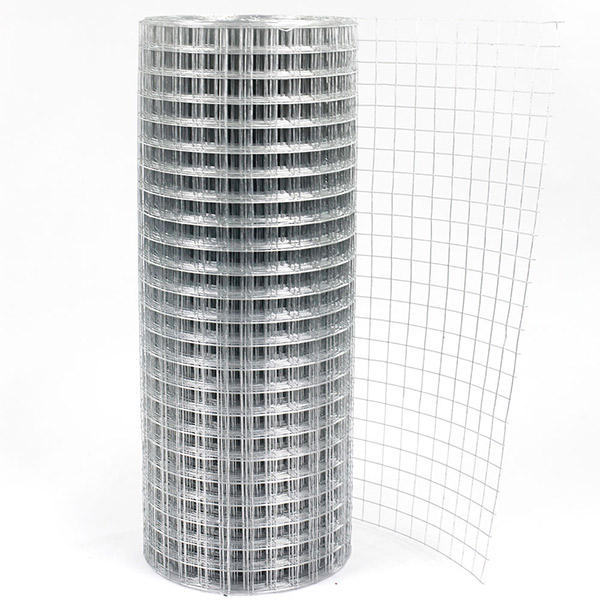

F72% reinforcing mesh is characterized by its specific design and composition, which allows it to maintain structural integrity under various loads and stresses. The F in its name refers to the mesh's formula, while 72% indicates its open area, effectively balancing strength and flexibility. This mesh is typically constructed from high-quality steel wire, which is welded together to form a grid-like pattern. This grid structure allows for even distribution of tensile forces, which is vital for preventing cracks and enhancing the overall longevity of concrete elements.

The Importance of F72% Reinforcing Mesh in Construction

One of the primary advantages of F72% reinforcing mesh is its ability to significantly improve the tensile strength of concrete. Concrete is inherently strong under compression but weak under tension. By incorporating reinforcing mesh, builders can create structures that withstand tensile stresses without cracking or failing. This is particularly important in areas prone to seismic activity or heavy loads, where structural resilience is paramount.

f72 reinforcing mesh factories

Additionally, F72% reinforcing mesh enhances crack control. As concrete cures, it undergoes various changes that can lead to cracking. By embedding reinforcing mesh within the matrix, these potential cracks can be minimized, ensuring a more uniform and stable structure over time. This increased durability can lead to reduced maintenance costs and extended lifespan for buildings and infrastructure.

Environmental considerations are also driving the adoption of F72% reinforcing mesh in construction. As the industry moves towards sustainability, using materials that enhance the lifespan of structures aligns with green building practices. By reducing the need for repair and replacement, F72% reinforcing mesh contributes to minimizing waste and the overall carbon footprint of construction projects.

Moreover, the manufacturing of F72% reinforcing mesh has evolved to incorporate advanced technologies and practices. Factories specializing in this type of mesh prioritize precision and quality control, ensuring that every batch meets stringent industry standards. This attention to detail not only guarantees the performance of the mesh but also provides peace of mind for engineers and architects involved in project design.

In conclusion, F72% reinforcing mesh is a critical component in modern construction. Its ability to enhance tensile strength, improve crack control, and contribute to sustainable building practices makes it an invaluable resource for contractors and builders alike. As the construction industry continues to innovate, reinforcing mesh like F72% will remain at the forefront, ensuring that our structures are not only durable but also efficient and environmentally friendly. The future of construction lies in the careful selection and application of materials that deliver unmatched performance, safety, and sustainability.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025