Aug . 11, 2024 20:14 Back to list

Exploring the Top Manufacturers of Welded Wire Mesh Products for Various Industrial Applications

The Importance of Welded Wire Mesh in Modern Manufacturing

Welded wire mesh, often referred to as welded wire fabric, has become an integral component in various industries due to its versatility, strength, and ease of use. This mesh material is fabricated by welding wire intersections together at various intervals, creating a sturdy grid pattern that is both durable and reliable. As industries grow and evolve, the demand for welded wire mesh factories increases, reflecting its importance in manufacturing, construction, and various applications.

Applications of Welded Wire Mesh

Welded wire mesh is widely used in construction projects. It serves multiple purposes, such as reinforcing concrete structures, creating fences, and providing a support framework for various building elements. In concrete reinforcement, welded wire mesh enhances the tensile strength of the concrete, preventing cracking and ensuring longevity. This is particularly vital in areas subjected to heavy loads or environmental stresses.

Additionally, welded wire mesh is utilized in agricultural applications. Farmers often employ this mesh for fencing to protect crops from animals and to create pens for livestock. Its durability against weather and physical impacts makes it ideal for such applications, ensuring that farms can operate efficiently without constant need for repair or replacement.

In the industrial sector, welded wire mesh finds use in manufacturing processes, such as filtration, sieving, and separation. Its fine structure can be tailored to meet specific needs, allowing for effective sorting of raw materials. Furthermore, its robustness accommodates heavy usage, making it a preferred choice for conveyor belts and sorting systems.

The Manufacturing Process

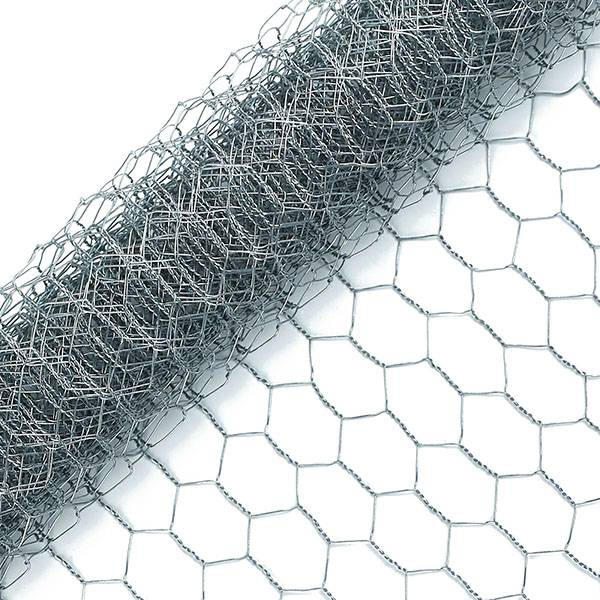

weld wire mesh factories

The production of welded wire mesh involves several steps, beginning with the selection of raw materials. High-quality steel wires are typically chosen for their strength and resistance to corrosion. The wires are then drawn to the required thickness before being cut to desired lengths for the mesh panels.

Next, the wires are arranged in a grid pattern, where they are expertly welded at each intersection. This welding process is crucial as it ensures a strong bond between the wires, resulting in a mesh that can withstand considerable tension and weight. After welding, the mesh panels undergo a quality control process to ensure they meet industry standards.

Once approved, the welded wire mesh can be further treated with galvanization or other protective coatings to enhance its resistance to rust and corrosion, especially in outdoor or harsh environments. This additional step is vital for extending the product's lifespan and maintaining its structural integrity.

Environmental Considerations

As manufacturers recognize their responsibility toward the environment, many welded wire mesh factories are adopting sustainable practices. This includes using recycled materials for wire production, minimizing waste during the manufacturing process, and developing eco-friendly coatings. These initiatives not only help in reducing the environmental impact but also align with the increasing demand for sustainable construction practices in the modern world.

Conclusion

Welded wire mesh plays a crucial role in various sectors, from construction and agriculture to manufacturing and filtration processes. Its strength, versatility, and adaptability make it a go-to solution for many applications. As the industry continues to grow, the importance of skilled welded wire mesh factories becomes even more pronounced, ensuring that the needs of contemporary society are met efficiently and sustainably. Looking forward, the evolution of technologies in manufacturing methods will likely further enhance the capabilities and applications of welded wire mesh, solidifying its place as an essential material in the industrial landscape.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025