Aug . 06, 2024 13:31 Back to list

Exploring Reliable OEM Service Providers for High-Quality Chain Link Fence Manufacturing Solutions

Understanding OEM Service in Chain Link Fence Manufacturing

In the modern manufacturing landscape, OEM (Original Equipment Manufacturer) services have gained significant traction across various industries, including the production of chain link fences. This process involves a dedicated manufacturer that produces goods according to the specifications and designs provided by another company, often a brand or retailer. By leveraging OEM services, businesses can enhance their product offerings, streamline production costs, and maintain high-quality standards. Let’s delve deeper into how OEM services work within the context of chain link fence manufacturing.

The Chain Link Fence Market

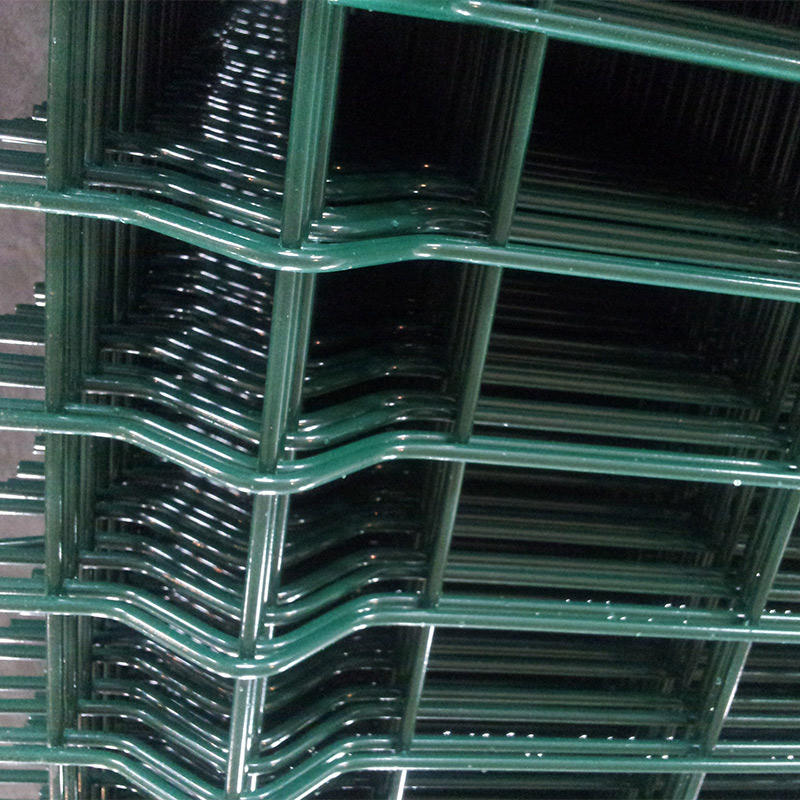

Chain link fences are widely used for both residential and commercial applications due to their durability, affordability, and versatility. These fences can provide security, define property boundaries, and even serve aesthetic purposes when properly designed. As demand continues to grow, manufacturers are increasingly turning to OEM services to keep pace with market requirements.

Key Benefits of OEM Services

1. Cost Efficiency One of the primary advantages of utilizing OEM services in chain link fence production is cost-effectiveness. By outsourcing manufacturing to specialized companies, brands can reduce overhead costs related to equipment, labor, and maintenance. This is particularly valuable for small and medium-sized enterprises that may not have the capital to invest in extensive manufacturing capabilities.

2. Expertise and Innovation OEM manufacturers often possess specialized knowledge and technical expertise in producing chain link fences. They are familiar with industry standards, regulatory requirements, and the latest manufacturing technologies. This expertise enables them to innovate and improve product designs, ensuring that the fences are not only functional but also meet contemporary aesthetic preferences.

3. Flexibility and Scalability With OEM services, companies can easily scale their production based on demand fluctuations. Whether it is a surge in orders during peak seasons or the need for a limited production run, OEM partners can adjust their manufacturing processes accordingly, providing the flexibility that brands require to stay competitive in the market.

oem service chain link fence manufacturers

4. Focus on Core Competencies By subcontracting manufacturing activities, businesses can refocus their efforts on core areas such as marketing, customer service, and product development. This strategic allocation of resources allows companies to build stronger brand identities and enhance customer relationships, which are crucial for long-term success.

The Process of Working with OEM Manufacturers

Engaging with an OEM chain link fence manufacturer typically involves several key steps. First, the brand must identify a suitable OEM partner with a proven track record in fence manufacturing. Once a partnership is established, the company will share design specifications, quality standards, and production timelines.

The OEM manufacturer will then create prototypes and submit them for approval. After ensuring that the products meet the required specifications, the manufacturer will commence mass production. Throughout this process, regular communication between the brand and the OEM partner is essential to address any potential issues or adjustments needed.

Quality Control and Compliance

Ensuring quality control is vital in any manufacturing process, and this is no exception when it comes to chain link fences. OEM manufacturers often adhere to stringent quality assurance protocols to ensure that the final products meet industry standards and customer requirements. Moreover, compliance with local and international regulations is critical, especially for businesses looking to export their products.

Conclusion

In conclusion, OEM services play a pivotal role in the chain link fence manufacturing sector. This collaborative approach allows brands to maintain a competitive edge by optimizing production while focusing on their core strengths. As the market for chain link fences continues to evolve, the relationship between brands and OEM manufacturers will likely grow ever more crucial in addressing customer demands and fostering innovation. Embracing OEM services can unlock new opportunities for growth and efficiency in this dynamic industry.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025