Aug . 12, 2024 18:46 Back to list

Exploring Manufacturers of 1% Welded Wire Mesh for Diverse Industrial Applications and Quality Standards

The Rise of 1 x 1 Welded Wire Mesh Factories An Essential Component in Modern Construction

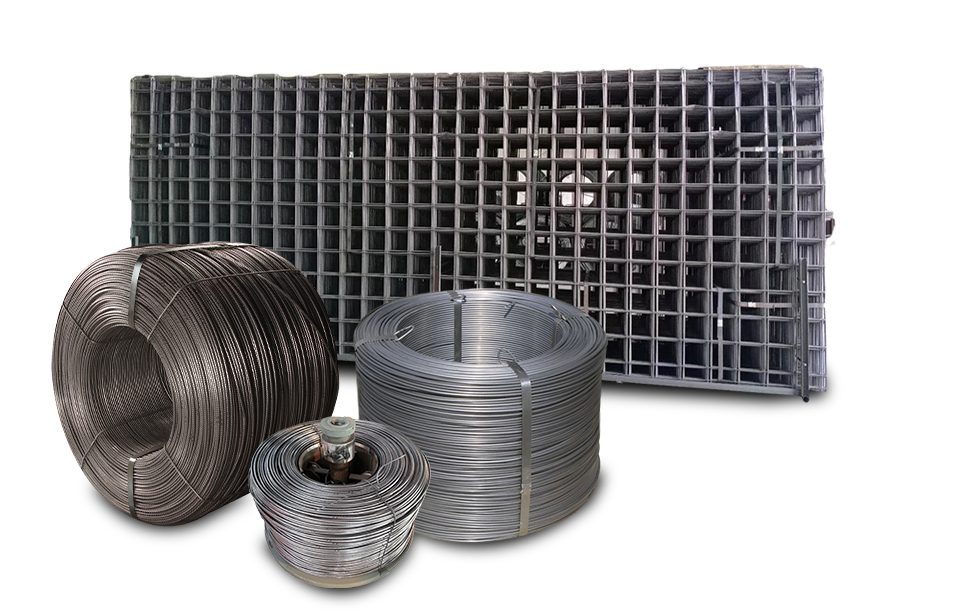

In recent years, the construction industry has seen an increased reliance on specialized materials that enhance structural integrity and provide innovative solutions to common challenges. One such material is welded wire mesh, particularly the 1 x 1 variant, renowned for its durability and versatility. With an ever-growing demand for this product, the emergence of dedicated 1 x 1 welded wire mesh factories has become a significant trend in the manufacturing sector.

The Rise of 1 x 1 Welded Wire Mesh Factories An Essential Component in Modern Construction

One of the primary benefits of establishing 1 x 1 welded wire mesh factories is the ability to streamline the manufacturing process. These factories utilize advanced machinery that optimizes production efficiency, reduces waste, and ensures consistent quality across batches. By leveraging automation and modern welding techniques, manufacturers can produce large quantities of mesh while adhering to stringent quality standards. This capability meets the demand of the construction industry for reliable materials that can expedite project timelines without compromising safety or performance.

1 x 1 welded wire mesh factories

Moreover, the rise of 1 x 1 welded wire mesh factories has contributed to local economies. As these factories emerge, they create job opportunities in manufacturing, engineering, and logistics, fostering economic growth within communities. In addition, sourcing materials locally reduces transportation costs and environmental impact, further enhancing the sustainability of construction practices.

The versatility of 1 x 1 welded wire mesh extends beyond commercial construction; it finds applications in residential projects, agricultural sectors, and fencing solutions. For instance, in the agricultural sector, it is used to create sturdy enclosures for livestock and to support climbing plants in gardens. In residential construction, it can be employed in foundations, driveways, and patios, providing homeowners with a reliable and cost-effective solution for structural reinforcement.

However, like any industry, the welded wire mesh manufacturing sector faces challenges. The fluctuating prices of raw materials, particularly steel, can impact production costs and, consequently, pricing strategies. Additionally, the shift towards sustainable and eco-friendly practices necessitates that factories adopt greener manufacturing techniques, such as using recycled materials and reducing energy consumption. This transition requires investment but is increasingly becoming a standard expectation from both consumers and regulatory bodies.

In conclusion, the emergence of 1 x 1 welded wire mesh factories represents a pivotal development in the construction industry. By providing a crucial material that enhances the strength and safety of structures, these factories not only meet the growing demand for reinforced concrete but also contribute to local economies and promote sustainable practices. As the industry continues to evolve, the role of welded wire mesh will undoubtedly remain central to modern construction methodologies, paving the way for safer, more resilient infrastructure.

-

Chain Link Fence - Anping County Puersen | Durable, Versatile Fencing

NewsAug.15,2025

-

Chain Link Fence-Galvanized Steel Fence Factory|Durable Security&Wire Mesh

NewsAug.15,2025

-

Chain Link Fence: Durable & Versatile Security Solution | Anping County Puersen Hardware Wire Mesh Products Co., Ltd.

NewsAug.15,2025

-

Chain Link Fence-Durable&Versatile|Anping County Puersen

NewsAug.15,2025

-

Welded Wire Mesh for Industry: Factory Supplier of Quality Mesh

NewsAug.15,2025

-

Chain Link Fence - Anping County Puersen Hardware Wire Mesh Products Co., Ltd.|Durable, Versatile, Reliable Fencing Solution

NewsAug.14,2025