Aug . 10, 2024 01:45 Back to list

Exploring Leading Manufacturers of Quality Wire Mesh Rolls for Diverse Applications and Industries

The Rise of Wire Mesh Rolls Factories A Key Component in Modern Manufacturing

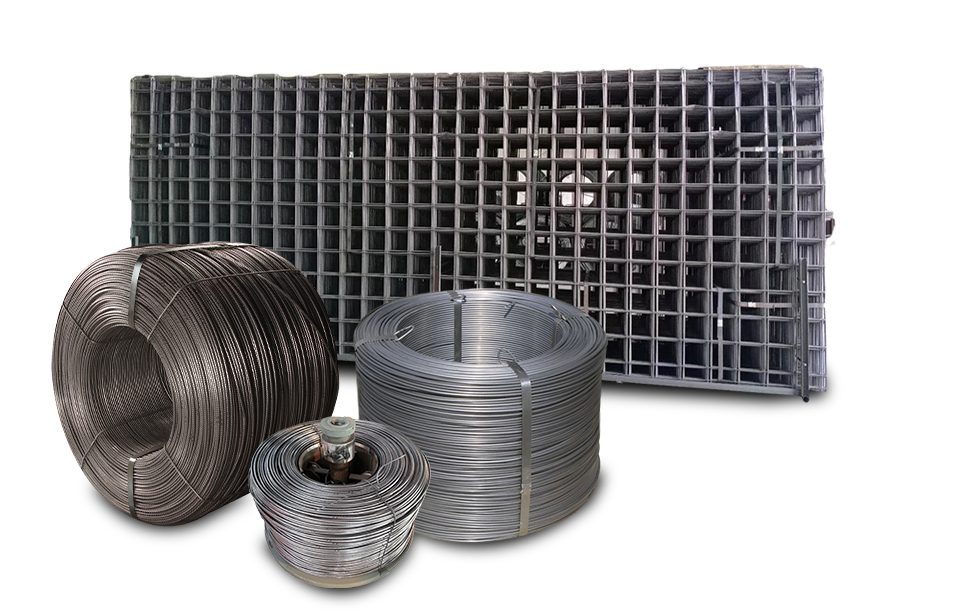

In recent years, the demand for wire mesh rolls has skyrocketed, driven by their diverse applications across various industries such as construction, agriculture, mining, and security. As a result, wire mesh rolls factories have proliferated, innovating and expanding to meet the increasing market needs.

Wire mesh rolls, made from high-quality steel or other metals, serve a multitude of purposes. They are primarily utilized for fencing, reinforcement in concrete, screening, and as barriers in construction projects. Their versatility makes them an indispensable element in both industrial and residential projects. With the growth of urbanization and infrastructural developments worldwide, the relevance of wire mesh rolls has never been greater.

Manufacturing Process

The manufacturing of wire mesh rolls typically involves several stages, each requiring precision and attention to detail. The process begins with the selection of raw materials. High-quality steel wire is preferred due to its strength and durability. The wire is then fed into machines that cut, weave, or weld it into various mesh configurations. Factories employ different techniques such as welded wire mesh, woven wire mesh, and expanded metal mesh, depending on the intended application.

Technological advancements have played a significant role in enhancing the efficiency of wire mesh production. Automated machinery now makes it possible to produce large quantities of wire mesh rolls with minimal human intervention. This shift not only boosts productivity but also reduces the likelihood of errors, resulting in higher-quality products. Moreover, factories are increasingly investing in eco-friendly practices, minimizing waste and focusing on sustainable sourcing of materials.

Market Demand and Trends

wire mesh rolls factories

The surge in demand for wire mesh rolls can be attributed to several trends. The construction industry, in particular, is a significant consumer, as wire mesh is crucial for reinforcing cement and concrete structures. Additionally, the growing focus on agricultural productivity has spurred the use of wire mesh in fencing livestock and crop protection. Furthermore, increasing security concerns have led to a rise in the use of wire mesh for perimeter fencing and protective barriers in both urban and rural settings.

Geographically, the demand for wire mesh rolls is witnessing significant growth in developing regions, where infrastructure projects are booming. Countries in Asia, Africa, and Latin America are investing heavily in road, bridge, and building constructions, thus driving the wire mesh industry forward. In developed nations, the focus is shifting towards renovation and eco-friendly construction practices, further bolstering the demand for specialized wire mesh products.

Challenges and Opportunities

Despite the growth in the industry, wire mesh rolls factories face challenges. Fluctuating raw material prices can impact production costs and profit margins. Additionally, competition is fierce, with numerous manufacturers vying for market share. Factories must continuously innovate and improve product offerings to remain competitive. This has led to developments in customized wire mesh solutions that cater to specific client needs, providing an opportunity for factories to differentiate themselves from competitors.

Moreover, as industries evolve, so do the requirements for wire mesh products. Factories must stay abreast of technological advancements and market trends, investing in research and development to create innovative solutions. This adaptability is crucial for long-term sustainability in a rapidly changing market.

Conclusion

In conclusion, wire mesh rolls factories play a vital role in supporting various sectors of the economy. Their ability to produce high-quality, versatile products keeps pace with the evolving demands of modern manufacturing. As the industry continues to expand, these factories must adapt to changing market conditions, embrace technological advancements, and maintain a commitment to sustainability. The future of wire mesh rolls is bright, filled with opportunities for growth, innovation, and contribution to a more interconnected world.

-

Chain Link Fence - Anping County Puersen | Durable, Versatile Fencing

NewsAug.15,2025

-

Chain Link Fence-Galvanized Steel Fence Factory|Durable Security&Wire Mesh

NewsAug.15,2025

-

Chain Link Fence: Durable & Versatile Security Solution | Anping County Puersen Hardware Wire Mesh Products Co., Ltd.

NewsAug.15,2025

-

Chain Link Fence-Durable&Versatile|Anping County Puersen

NewsAug.15,2025

-

Welded Wire Mesh for Industry: Factory Supplier of Quality Mesh

NewsAug.15,2025

-

Chain Link Fence - Anping County Puersen Hardware Wire Mesh Products Co., Ltd.|Durable, Versatile, Reliable Fencing Solution

NewsAug.14,2025