Aug . 13, 2024 19:36 Back to list

Exploring Leading Manufacturers of Diamond Steel Grating and Their Quality Standards in the Industry

Understanding Diamond Steel Grating Factories

Diamond steel grating has become an integral component in various industries, playing a critical role in providing safety, durability, and functionality. As industries continue to evolve, the demand for high-quality steel grating has surged, leading to the establishment of numerous diamond steel grating factories worldwide. This article delves into the significance of diamond steel grating factories, the production processes, and their applications across different sectors.

What is Diamond Steel Grating?

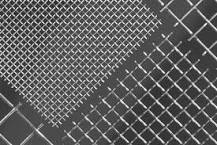

Diamond steel grating refers to a type of floor grating made from steel, characterized by its diamond-shaped openings. This design not only enhances aesthetic appeal but also promotes better drainage, reduces weight, and improves traction. The diamond pattern is a crucial feature that ensures it can withstand heavy loads while providing a slip-resistant surface, making it ideal for various environments.

The Importance of Diamond Steel Grating Factories

The emergence of diamond steel grating factories is a response to the increasing demand for safety and efficiency in industrial operations. Factories specializing in the production of diamond steel grating offer several advantages

1. Quality Assurance These factories implement stringent quality control measures to ensure that the grating meets industry standards. This is particularly crucial in applications where safety is paramount, such as in construction sites, industrial facilities, and public infrastructure.

2. Customization With advanced manufacturing technologies, many diamond steel grating factories offer customization options, allowing clients to request specific dimensions, load ratings, and finishes. This flexibility caters to a wide range of applications across various sectors.

3. Cost-Effectiveness By producing steel grating in bulk, factories can reduce costs that can be passed on to consumers. This affordability makes diamond steel grating accessible to a broader market, including small businesses and startups.

4. Innovation With the rise of technology, many factories are incorporating automated processes and advanced machinery in their production lines. This not only increases efficiency but also enhances the precision of the grating, leading to higher quality products.

Manufacturing Process

The production of diamond steel grating involves several steps

diamond steel grating factories

1. Material Selection High-quality steel is selected based on the required strength and durability. Factors like corrosion resistance and load capacity are considered during this stage.

2. Cutting and Forming The steel sheets are cut into desired sizes. The diamond pattern is created through a combination of stamping and forming techniques, ensuring precision.

3. Welding Crossbars are often welded onto the stairstep pattern to provide additional support. The welding process requires skilled labor to guarantee the integrity of the connections.

4. Finishing The grating is then subjected to various finishing processes, such as galvanizing or powder coating. These treatments enhance corrosion resistance and prolong the lifespan of the product.

5. Quality Check Before shipping, each batch undergoes rigorous quality tests to ensure they meet the necessary standards for strength, durability, and safety.

Applications of Diamond Steel Grating

Diamond steel grating finds its applications in numerous fields

- Construction Often used as flooring, walkways, or staircases in buildings, diamond grating provides safety and durability. - Manufacturing In manufacturing plants, it is commonly used for platforms and machinery supports, where strength and safety are non-negotiable.

- Transportation Diamond steel grating is utilized in railway platforms, ramps, and bridges, where it enhances safety for pedestrians and vehicles alike.

- Environmental Applications In wastewater treatment facilities, diamond grating is employed for cover and access solutions, ensuring efficient drainage and structural integrity.

In conclusion, the growth of diamond steel grating factories reflects the increasing need for reliable and efficient industrial solutions. With their commitment to quality, innovation, and customer satisfaction, these factories play a pivotal role in enhancing safety and functionality across various sectors. As demand continues to rise, the future of diamond steel grating manufacturing looks promising, with ongoing advancements in technology expected to further improve product offerings.

-

12mm Stainless Steel Wire Mesh for Industrial & Commercial Use Top Quality Factories & Manufacturers

NewsJun.24,2025

-

Black Annealed Wire Specification - High Quality & Custom Options from Leading Factories, Suppliers, Manufacturers

NewsJun.10,2025

-

High-Quality 18 Gauge Black Steel Wire Reliable Factories & Suppliers

NewsJun.10,2025

-

Chain Link Fence Gates - Durable & Secure Access Solutions

NewsJun.10,2025

-

Premium Cold Rolled Steel Bar Supplier High Strength & Precision

NewsJun.10,2025

-

Galvanized Wire Brick Force Mesh - Corrosion Resistant

NewsJun.09,2025