Jun . 14, 2024 15:36 Back to list

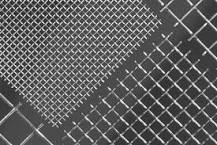

Expanded diamond mesh sheet metal.

The concept of a diamond mesh expanded sheet is an intriguing one, blending the elegance of geometry with the functionality of modern materials science. In this brief exploration, we will delve into what exactly constitutes such a material and why it might be of interest to engineers, architects, and designers alike.

A diamond mesh expanded sheet can be visualized as a thin, pliable layer composed of a network of interconnected diamond-shaped openings. These sheets are typically made from metals, plastics, or composite materials that have been perforated and then expanded to create a lattice-like structure. The process not only imparts unique mechanical properties but also reduces material usage, making it more cost-effective and environmentally friendly compared to solid sheets.

One of the primary advantages of using a diamond mesh expanded sheet lies in its strength-to-weight ratio. Despite having numerous open areas, the clever arrangement of the remaining material provides excellent structural support. This characteristic makes them ideal for applications where weight is a critical factor, such as in aerospace components, automotive parts, and architectural facades.

Moreover, the open-weave design allows for air and light to pass through, creating opportunities for ventilation and illumination while maintaining privacy. In architectural settings, this can lead to energy savings by reducing the need for artificial lighting and air conditioning In architectural settings, this can lead to energy savings by reducing the need for artificial lighting and air conditioning In architectural settings, this can lead to energy savings by reducing the need for artificial lighting and air conditioning In architectural settings, this can lead to energy savings by reducing the need for artificial lighting and air conditioning

In architectural settings, this can lead to energy savings by reducing the need for artificial lighting and air conditioning In architectural settings, this can lead to energy savings by reducing the need for artificial lighting and air conditioning diamond mesh expanded sheet. The visual appeal of the patterned light cast by these sheets further enhances their aesthetic value in modern building designs.

Diamond mesh expanded sheets also find utility in industrial filters and grating due to their ability to allow fluids and particles to pass through while trapping larger debris. They are durable and easy to clean, making maintenance simpler and extending their service life.

In terms of manufacturing, diamond mesh expanded sheets can be produced in large sizes with consistent quality, thanks to automated processes. This scalability ensures that they can cover vast areas quickly, whether it's for a decorative facade on a skyscraper or a protective barrier on a highway construction site.

In conclusion, the diamond mesh expanded sheet represents a marvel of engineering and design, marrying form and function in a way that is both practical and aesthetically pleasing. Its versatility across various industries, coupled with its sustainability benefits, makes it a material worth considering for those seeking innovative solutions to design challenges.

diamond mesh expanded sheet. The visual appeal of the patterned light cast by these sheets further enhances their aesthetic value in modern building designs.

Diamond mesh expanded sheets also find utility in industrial filters and grating due to their ability to allow fluids and particles to pass through while trapping larger debris. They are durable and easy to clean, making maintenance simpler and extending their service life.

In terms of manufacturing, diamond mesh expanded sheets can be produced in large sizes with consistent quality, thanks to automated processes. This scalability ensures that they can cover vast areas quickly, whether it's for a decorative facade on a skyscraper or a protective barrier on a highway construction site.

In conclusion, the diamond mesh expanded sheet represents a marvel of engineering and design, marrying form and function in a way that is both practical and aesthetically pleasing. Its versatility across various industries, coupled with its sustainability benefits, makes it a material worth considering for those seeking innovative solutions to design challenges.

In architectural settings, this can lead to energy savings by reducing the need for artificial lighting and air conditioning In architectural settings, this can lead to energy savings by reducing the need for artificial lighting and air conditioning

In architectural settings, this can lead to energy savings by reducing the need for artificial lighting and air conditioning In architectural settings, this can lead to energy savings by reducing the need for artificial lighting and air conditioning diamond mesh expanded sheet. The visual appeal of the patterned light cast by these sheets further enhances their aesthetic value in modern building designs.

Diamond mesh expanded sheets also find utility in industrial filters and grating due to their ability to allow fluids and particles to pass through while trapping larger debris. They are durable and easy to clean, making maintenance simpler and extending their service life.

In terms of manufacturing, diamond mesh expanded sheets can be produced in large sizes with consistent quality, thanks to automated processes. This scalability ensures that they can cover vast areas quickly, whether it's for a decorative facade on a skyscraper or a protective barrier on a highway construction site.

In conclusion, the diamond mesh expanded sheet represents a marvel of engineering and design, marrying form and function in a way that is both practical and aesthetically pleasing. Its versatility across various industries, coupled with its sustainability benefits, makes it a material worth considering for those seeking innovative solutions to design challenges.

diamond mesh expanded sheet. The visual appeal of the patterned light cast by these sheets further enhances their aesthetic value in modern building designs.

Diamond mesh expanded sheets also find utility in industrial filters and grating due to their ability to allow fluids and particles to pass through while trapping larger debris. They are durable and easy to clean, making maintenance simpler and extending their service life.

In terms of manufacturing, diamond mesh expanded sheets can be produced in large sizes with consistent quality, thanks to automated processes. This scalability ensures that they can cover vast areas quickly, whether it's for a decorative facade on a skyscraper or a protective barrier on a highway construction site.

In conclusion, the diamond mesh expanded sheet represents a marvel of engineering and design, marrying form and function in a way that is both practical and aesthetically pleasing. Its versatility across various industries, coupled with its sustainability benefits, makes it a material worth considering for those seeking innovative solutions to design challenges. Latest news

-

Glass Jar with Wooden Screw Lid-Anping County Puersen Hardware Wire Mesh Products Co.,Ltd|Thermal Resistance&Eco-Friendly

NewsAug.17,2025

-

Glass Food Storage Jar with Screw Wooden Lid - Anping County Puersen Hardware Wire Mesh Products Co., Ltd|High Borosilicate Glass&Eco-Friendly Design

NewsAug.17,2025

-

Glass Food Storage Jar with Screw Wooden Lid - Anping County Puersen Hardware Thermal Resistance Eco-Friendly Airtight Seal

NewsAug.17,2025

-

Glass Jar with Wooden Screw Lid - Anping County Puersen Hardware Wire Mesh Products Co., Ltd

NewsAug.17,2025

-

Diamond Steel Grating Factory: Leading Manufacturer & Supplier

NewsAug.17,2025

-

Glass Food Storage Jar with Screw Wooden Lid - Premium Eco-Friendly Storage Solution|Anping County Puersen Hardware Wire Mesh Products Co.,Ltd

NewsAug.16,2025