Oct . 12, 2024 01:46 Back to list

electro galvanized wire low price factory

Electro Galvanized Wire Affordable Quality from Reliable Factories

Electro galvanized wire is a popular choice for various applications, ranging from construction and fencing to electrical installations. As industries continue to seek cost-effective solutions without compromising on quality, the demand for low-priced electro galvanized wire from factories has surged. This article explores the benefits of electro galvanized wire, its applications, and what to consider when choosing a factory for your supply needs.

Understanding Electro Galvanized Wire

Electro galvanized wire is coated with a layer of zinc through an electroplating process. This treatment offers excellent corrosion resistance, making it ideal for environments that may expose the wire to moisture and other corrosive elements. The coating not only enhances the durability of the wire but also provides a sleek, shiny finish that many find aesthetically pleasing.

One of the primary reasons for its popularity is the cost-effectiveness of electro galvanized wire compared to hot-dip galvanized wire. While hot-dip galvanized wire provides thicker zinc coatings, electro galvanized wire is often sufficient for many applications and comes at a lower price point. The balance of performance and affordability makes it an attractive option for manufacturers and consumers alike.

Applications of Electro Galvanized Wire

Electro galvanized wire is versatile, serving multiple sectors

1. Fencing It is commonly used in agricultural applications to create fences that protect crops and livestock. The anti-corrosive properties ensure that the fencing material will last longer under various weather conditions.

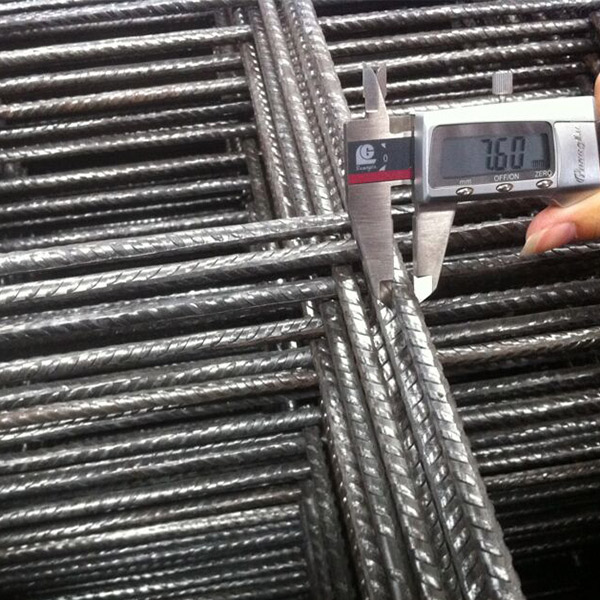

2. Construction Builders use electro galvanized wire in concrete reinforcement and as a binding agent for structural elements. Its strength and resistance to rusting make it a reliable choice in construction projects.

3. Electrical Wiring In electrical applications, electro galvanized wire is used for underground connections and other installations where moisture is a concern. The zinc coating prevents short circuits and enhances safety.

electro galvanized wire low price factory

4. Craft and DIY Projects Artisans and hobbyists often incorporate electro galvanized wire into their projects due to its malleability and easy handling.

Choosing a Reliable Factory

When sourcing electro galvanized wire, choosing the right factory is crucial to ensure quality and cost-effectiveness. Here are some tips to consider

- Reputation and Reviews Look for factories with a solid reputation and positive customer reviews. Researching past projects and client feedback can provide insight into the factory’s reliability and product quality.

- Quality Standards Ensure that the factory adheres to industry quality standards and certifications. This guarantees that the wire produced meets specific durability and safety criteria.

- Price Competitiveness While low prices can be tempting, be cautious of factories that offer prices significantly lower than the market average without justification. Such prices may indicate compromised quality.

- Customer Support A factory that provides excellent customer service can make your purchasing experience smoother. Clear communication, responsiveness, and after-sales support should be considered when selecting a factory.

- Sample Requests Requesting samples before making a bulk purchase can help assess the product's quality and suitability for your application.

Conclusion

Electro galvanized wire presents an affordable yet high-quality solution for various applications, making it a sought-after choice in today's market. By understanding its advantages and knowing what to look for in a factory, businesses can secure reliable supplies that meet their needs while staying within budget. As industries continue to evolve, investing in quality electro galvanized wire from reputable factories will remain a smart choice for cost-conscious consumers.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025