Aug . 21, 2024 21:01 Back to list

Durable Steel Mesh for Concrete Reinforcement in Construction Applications

Understanding Concrete Reinforcement Wire Mesh

Concrete is one of the most widely used construction materials globally, admired for its strength and durability. However, concrete has its limitations, particularly its susceptibility to cracking under tension and stress. To overcome these limitations, engineers and builders have turned to reinforcement techniques, among which concrete reinforcement wire mesh stands out as a preferred method.

What is Concrete Reinforcement Wire Mesh?

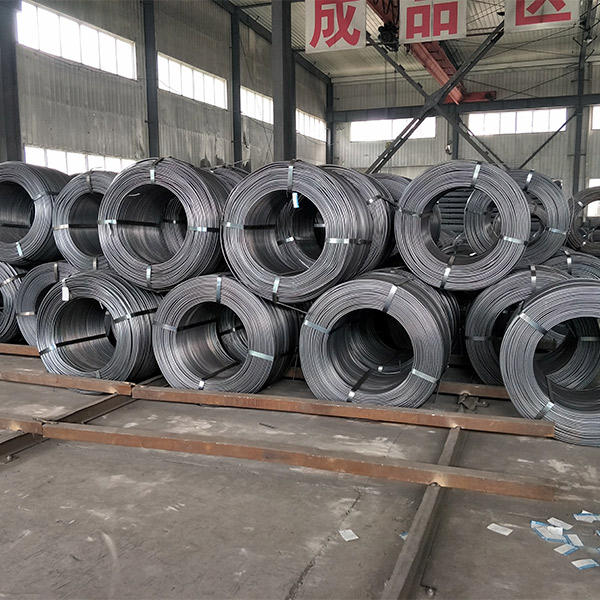

Concrete reinforcement wire mesh, commonly referred to as rebar mesh, is a grid-like structure made of steel wires. These wires are arranged in a series of parallel lines and are often welded together at the intersections to form a rigid framework. The mesh is available in different gauges and sizes, allowing it to accommodate various construction needs.

The primary purpose of reinforcement wire mesh is to provide tensile strength to concrete. While concrete is excellent in compression, it lacks in tensile strength—an essential property when structures are subjected to bending and stretching forces. By integrating wire mesh into concrete, builders essentially enhance the material's overall structural integrity.

Benefits of Using Wire Mesh in Concrete Structures

1. Crack Control One of the most significant advantages of using wire mesh is its ability to control cracking. Concrete naturally undergoes shrinkage as it cures, which can lead to surface cracking. Reinforcement mesh helps distribute loads more evenly, minimizing the chances of cracks forming.

2. Load Distribution Wire mesh helps in the even distribution of loads across the concrete surface. This is particularly crucial in flat slabs or pavement where heavy loads are expected. The mesh absorbs and disperses forces that might otherwise concentrate and lead to structural failure.

3. Ease of Installation Compared to traditional rebar, which requires intricate tying and placement, wire mesh is relatively easy to install. It can be laid in place quickly, allowing for faster construction times without sacrificing quality.

concrete reinforcement wire mesh

4. Cost-Effectiveness Given its structural benefits and ease of installation, concrete reinforcement wire mesh can ultimately lead to lower costs in both materials and labor over the lifecycle of the project. Less labor-intensive installation means reduced expenditure on labor.

Applications of Reinforcement Wire Mesh

Concrete reinforcement wire mesh is widely used across various construction sectors, including residential, commercial, and industrial projects. Common applications include

- Slabs Whether for driveways, patios, or flooring, wire mesh provides the necessary reinforcement to prevent cracking. - Walls In precast concrete wall systems, wire mesh enhances stability and durability. - Roads and Pavements The mesh is often used in road construction to ensure that pavements withstand the stresses imposed by vehicle traffic.

Choosing the Right Wire Mesh

Selecting the appropriate type of concrete reinforcement wire mesh involves considering factors such as gauge, size, and coating (if any). Different projects may require different specifications based on load requirements, environmental conditions, and the specific design of the structure.

Conclusion

In conclusion, concrete reinforcement wire mesh plays a vital role in modern construction, enhancing the overall performance and longevity of concrete structures. By addressing the inherent weaknesses of concrete with a solution that is both effective and efficient, builders can create safer and more durable buildings and infrastructure. Whether used in residential homes or large-scale commercial projects, the benefits of wire mesh cannot be overstated, making it an indispensable material in the construction industry. As we continue to innovate in construction methods and materials, reinforcement wire mesh remains a cornerstone of resilient structural design.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025