Jul . 28, 2024 00:35 Back to list

Durable Reinforcing Mesh Panels Manufactured Locally for Enhanced Construction and Structural Integrity Solutions

Understanding Reinforcing Mesh Panels A Guide to Factories and Their Importance

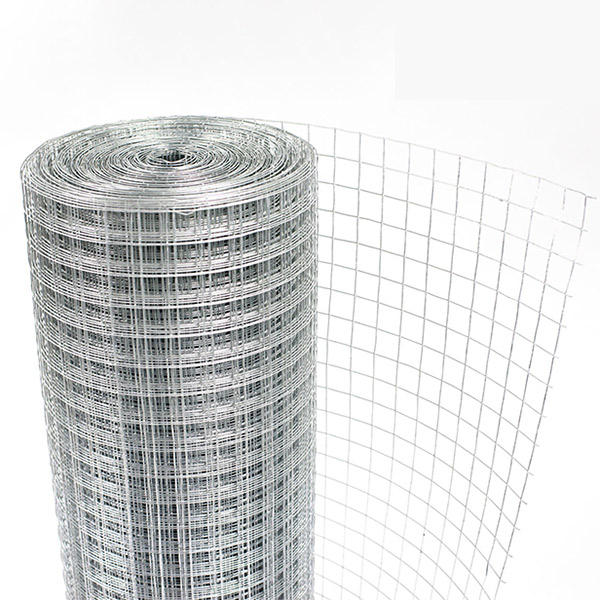

Reinforcing mesh panels are essential components in the construction industry, providing critical structural support for a wide range of applications. These panels, typically made from steel wire, enhance the strength and durability of concrete structures by uniformly distributing loads and preventing cracking. This article explores the significance of reinforcing mesh panels and highlights the factories that specialize in their production.

What Are Reinforcing Mesh Panels?

Reinforcing mesh panels consist of a lattice of interconnected steel wires. They come in various shapes, sizes, and wire diameters, tailored to meet specific structural requirements. These panels are widely used in concrete slabs, walls, foundations, and various other applications where additional strength is needed. The uniform grid pattern allows for effective load distribution, which minimizes the risk of structural failure over time.

The Role of Factories in Manufacturing Reinforcing Mesh Panels

Factories play a pivotal role in the production of reinforcing mesh panels. Equipped with advanced machinery and skilled labor, these facilities ensure that the panels meet strict quality standards. The manufacturing process typically involves several stages

1. Wire Production Manufacturers begin with high-quality steel wire, which is produced through a series of processes, including drawing, cutting, and treatment to enhance its tensile strength and durability.

2. Mesh Formation Once the wire is prepared, it is woven into a mesh configuration. This can be done through various methods, such as welding or mechanical tying, ensuring that the panels are robust and can withstand significant loads.

3. Quality Control Rigorous quality control checks are conducted at various stages of production. This may include testing the tensile strength of the wire, checking the precision of the mesh layout, and assessing the overall finish of the panels to ensure they meet industry standards and specifications.

reinforcing mesh panels factory

5. Distribution After production, these panels are prepared for distribution to construction sites. Effective logistics and supply chain management are crucial to ensure timely delivery, minimizing delays in building schedules.

The Importance of Reinforcing Mesh Panels in Construction

The use of reinforcing mesh panels in construction is paramount for several reasons

- Enhanced Structural Integrity The primary function of these panels is to increase the tensile strength of concrete, which is naturally strong in compression but weak in tension. By integrating reinforcing mesh, builders can create structures that better withstand various stresses and forces.

- Crack Prevention Concrete structures are susceptible to cracking due to temperature fluctuations, shrinkage, and settling. Reinforcing mesh panels help control cracking and improve the longevity of structures.

- Cost-Effective Solution Utilizing reinforcing mesh panels can lead to cost savings in construction projects. By minimizing the need for additional materials and labor for repairs, builders can allocate resources more efficiently.

- Versatility These panels are suitable for a wide range of applications, from residential buildings to large industrial facilities, making them a versatile choice for contractors and engineers.

Conclusion

Reinforcing mesh panels are a fundamental element in modern construction, providing essential support and durability to concrete structures. The factories that produce these panels are equipped with advanced technology and expertise, ensuring the highest standards of quality. As the demand for robust and resilient construction solutions continues to grow, reinforcing mesh panels will undoubtedly remain at the forefront of the industry, contributing to safer and more sustainable building practices worldwide.

-

High Quality Deformed Steel Bars China - Reliable Manufacturers & Suppliers for Construction Projects

NewsJul.08,2025

-

High Quality Black Annealed Wire - Durable Iron Wire 2mm from Leading Manufacturer & Supplier Factory

NewsJul.08,2025

-

Produce Hot Dipped Galvanized Steel Grating - High Quality Grating Supplier & Manufacturer

NewsJul.08,2025

-

Galvanized Iron Welded Wire Mesh Panels – Durable, Rust-Resistant, Best Price Manufacturer

NewsJul.07,2025

-

High Quality Concrete Reinforcing Welded Wire Mesh - Durable 8mm Steel Bar, Q188, A393, F72, High Strength Mesh Solutions

NewsJul.07,2025

-

High-Quality Redrawn G.I. Wire Leading Manufacturers & Suppliers

NewsJul.07,2025