Dec . 04, 2024 03:19 Back to list

diamond pvc welded wire mesh manufacturer

The Rise of Diamond PVC Welded Wire Mesh Manufacturers

In the realm of construction and industrial applications, materials that combine strength, durability, and versatility are essential. Among these, diamond PVC welded wire mesh has emerged as an innovative solution, favored for its robustness and functionality. This article explores the significance of diamond PVC welded wire mesh, the manufacturing process, applications, and the role of manufacturers in meeting the growing demand for this material.

Understanding Diamond PVC Welded Wire Mesh

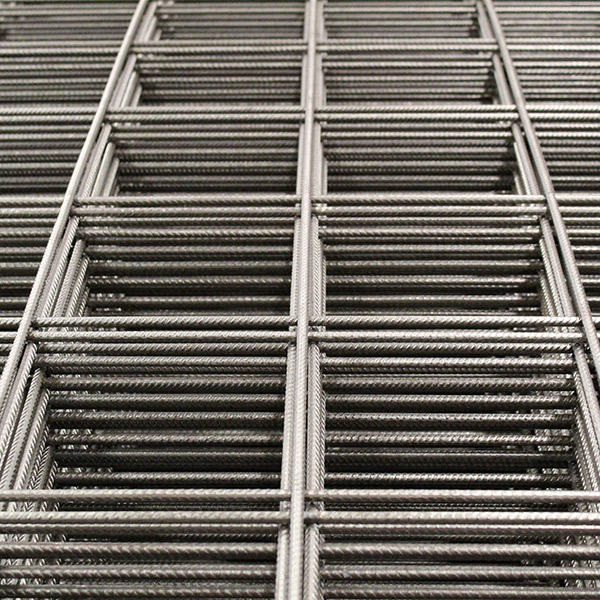

Diamond PVC welded wire mesh is a type of fencing and reinforcement material made from high-quality steel wire that is welded at intersections to form a strong grid, coated with a layer of polyvinyl chloride (PVC). The PVC coating enhances the wire’s resistance to corrosion, chemicals, and wear and tear, making it suitable for long-term use in both indoor and outdoor environments. The 'diamond' pattern refers to the specific design of the mesh, which provides optimal strength while allowing for airflow and visibility.

Advantages of Diamond PVC Welded Wire Mesh

1. Durability and Longevity The steel wire core provides substantial strength, while the PVC coating offers excellent protection against environmental factors, prolonging the lifespan of the mesh.

2. Versatility This mesh can be used in a variety of applications, including fencing, animal enclosures, gardens, and construction sites. Its flexible nature allows it to be adapted to different shapes and sizes.

3. Aesthetic Appeal The PVC coating is available in various colors, allowing users to choose a visually appealing design that complements their surroundings.

4. Low Maintenance The resistance to rust and rot means that diamond PVC welded wire mesh requires minimal maintenance, making it a cost-effective option for consumers.

Manufacturing Process of Diamond PVC Welded Wire Mesh

diamond pvc welded wire mesh manufacturer

The production of diamond PVC welded wire mesh involves several key steps

1. Wire Drawing High-quality steel rods are drawn into wires of desired thickness. This process is crucial as it determines the overall strength and flexibility of the finished product.

2. Welding The wires are arranged in a grid pattern and welded at the intersections to create a solid mesh structure. This step requires precision to ensure optimal strength and consistency.

3. Coating After welding, the mesh is coated with PVC. This can be done through various methods, such as electrostatic spraying or dip-coating, ensuring an even and durable layer that adheres well to the wire.

4. Cutting and Packaging Finally, the finished mesh is cut to size according to specifications and packaged for distribution.

The Role of Manufacturers

Manufacturers of diamond PVC welded wire mesh play a pivotal role in the supply chain, ensuring high-quality products are available to meet diverse customer needs. Leading manufacturers invest in advanced technology and skilled labor to maintain quality control throughout the production process. They often have the capability to customize products based on specific requirements, offering varying wire gauges, mesh sizes, and colors.

In addition, reputable manufacturers adhere to industry standards and regulations, providing customers with assurance regarding the safety and reliability of their products. Furthermore, they often engage in sustainable practices, such as recycling scrap material and minimizing waste during production.

Conclusion

Diamond PVC welded wire mesh stands out as a versatile and durable material in various sectors, driven by the innovative manufacturing practices of dedicated manufacturers. As demand grows for effective fencing and reinforcement solutions, the role of these manufacturers becomes increasingly important. By prioritizing quality and customization, they contribute significantly to meeting the needs of industries ranging from agriculture to construction, ensuring that clients receive products that not only meet but exceed their expectations. As we look to the future, the continued evolution of manufacturing techniques and materials is likely to further enhance the capabilities and applications of diamond PVC welded wire mesh, solidifying its place in the global market.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025