Nov . 21, 2024 22:58 Back to list

diamond mesh manufacturers

Understanding Diamond Mesh Manufacturers A Comprehensive Overview

When it comes to manufacturing materials for various applications, diamond mesh has gained significant popularity due to its unique properties and versatility. This type of mesh, which features a diamond-shaped pattern, is used in a variety of industries, ranging from construction to agriculture. To meet the growing demand for this product, numerous diamond mesh manufacturers have emerged. In this article, we will delve into what diamond mesh is, its applications, and what to consider when choosing a manufacturer.

What is Diamond Mesh?

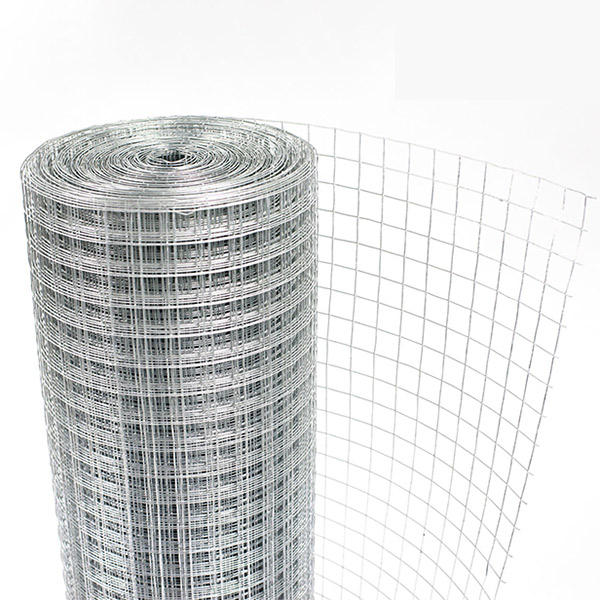

Diamond mesh is a type of woven wire mesh that is characterized by its diamond-shaped openings. Typically made from materials such as stainless steel, galvanized steel, or aluminum, it provides strength, durability, and flexibility. The specific arrangement of the wire allows for excellent visibility and ventilation, making it an ideal choice for various tasks. The mesh can be manufactured in different gauge sizes, which pertains to the thickness of the wire, thus influencing its strength and application.

Applications of Diamond Mesh

The versatility of diamond mesh makes it suitable for a plethora of applications

1. Construction It is often used in reinforcing concrete, providing structural integrity to buildings, bridges, and other infrastructures.

2. Agriculture Farmers utilize diamond mesh for fencing, protecting crops from pests and larger animals while allowing air and sunlight to reach the plants.

3. Industrial In factories and warehouses, diamond mesh is used for safety barriers, machine guards, and as a platform for loading and unloading materials.

4. Home Improvement It is also a popular choice for home projects, such as decorative fencing, room dividers, along with providing security for windows and doors.

5. Sports Facilities Diamond mesh is frequently employed in sports fields as netting for tennis courts, soccer fields, and other recreational areas, ensuring safety by containing balls within the play area.

diamond mesh manufacturers

Choosing a Diamond Mesh Manufacturer

With various manufacturers in the market, selecting the right one can be a daunting task. Here are some important considerations

1. Quality of Material High-quality materials guarantee longevity and durability. It’s essential to inquire about the raw materials used in the manufacturing process.

2. Production Capability Understanding a manufacturer’s capacity to produce diamond mesh can be crucial, especially for large-scale projects that require bulk orders.

3. Customization Options Different projects may require specific sizes, patterns, or gauges. Find manufacturers that offer customization to meet your exact needs.

4. Certifications and StandardsReputable manufacturers often comply with industry standards and certifications. This guarantees that their products meet safety and quality benchmarks.

5. Customer Reviews and Reputation Researching customer feedback and testimonials can provide insights into the manufacturer’s reliability and service quality.

6. Pricing While cost should not be the only factor, it’s always prudent to compare prices among manufacturers. Remember to weigh the cost against the quality and service offered.

7. After-sales Service A manufacturer that provides excellent after-sales support can make a significant difference, especially when issues arise or adjustments are needed post-purchase.

Conclusion

Diamond mesh is an essential material in various industries, and the choice of manufacturer plays a pivotal role in ensuring quality and reliability. By understanding the properties and applications of diamond mesh, along with the factors to consider when selecting a supplier, buyers can make informed decisions that lead to successful outcomes in their respective projects. Whether you are in construction, agriculture, or any other field, investing time in choosing the right diamond mesh manufacturer can pay dividends in quality, efficiency, and safety.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025