Jun . 13, 2024 15:50 Back to list

Diamond mesh production specialist

Understanding the Art of Diamond Mesh Manufacturing

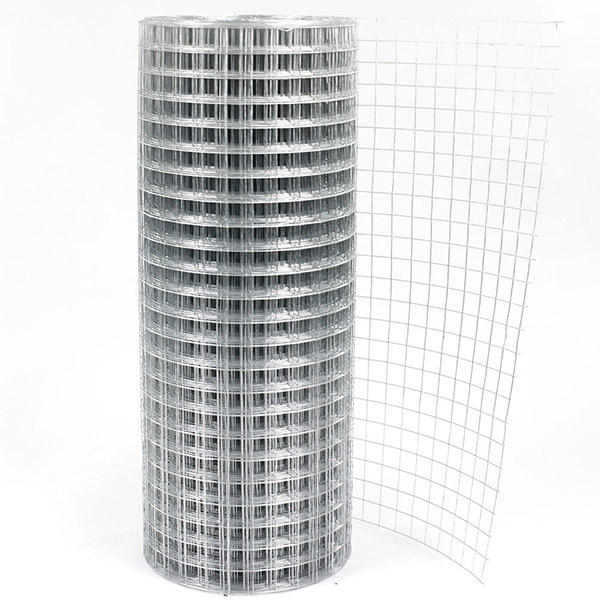

In the realm of industrial materials, one product that stands out for its strength and versatility is the diamond mesh. This unique mesh, often referred to as diamond wire mesh or diamond patterned mesh, finds application in various sectors ranging from construction to agriculture, mining to filtration systems. The key to its success lies in the hands of skilled diamond mesh manufacturers.

A diamond mesh manufacturer is a specialist in crafting this distinctive mesh, which is characterized by its square openings with a diamond-shaped configuration. The process begins with selecting high-quality raw materials, typically steel wires, stainless steel, or aluminum, depending on the intended use and environmental conditions. These wires are then subjected to a rigorous manufacturing process that includes weaving, welding, or punching, ensuring durability and resilience.

The weaving method, for instance, involves intertwining wires in a crisscross pattern, creating the iconic diamond pattern. Welding, on the other hand, involves joining individual wires at their intersections to form the mesh. This method is often favored for its strength and resistance to wear and tear. Punching, another technique, involves cutting out the diamond shapes from a solid sheet, offering precision and consistency.

Once the mesh is formed, it undergoes strict quality control measures to ensure it meets industry standards. This includes tests for tensile strength, corrosion resistance, and overall structural integrity. The final product can be customized to meet specific requirements, be it in terms of size, aperture, or material The final product can be customized to meet specific requirements, be it in terms of size, aperture, or material The final product can be customized to meet specific requirements, be it in terms of size, aperture, or material The final product can be customized to meet specific requirements, be it in terms of size, aperture, or material

The final product can be customized to meet specific requirements, be it in terms of size, aperture, or material The final product can be customized to meet specific requirements, be it in terms of size, aperture, or material diamond mesh manufacturer.

Diamond mesh manufacturers not only contribute to the production of this robust material but also play a crucial role in innovation. They continually strive to improve the mesh's performance, introducing new alloys, coatings, and manufacturing techniques to enhance its properties. Some manufacturers even offer eco-friendly options, such as using recycled materials or developing meshes that are more sustainable over time.

The applications of diamond mesh are numerous and diverse. In construction, it serves as reinforcement in concrete structures, providing stability and strength. In agriculture, it's used for animal enclosures and crop protection. Mining industries utilize it for sieving and screening operations, while in filtration systems, it helps separate solids from liquids effectively.

In conclusion, the diamond mesh manufacturer is an integral part of the industrial supply chain. Their expertise, precision, and commitment to quality ensure that this versatile material continues to serve a multitude of purposes across various sectors. Whether it's reinforcing a towering skyscraper or protecting a delicate ecosystem, the diamond mesh, crafted diligently by these manufacturers, stands as a testament to human ingenuity and the power of engineering.

diamond mesh manufacturer.

Diamond mesh manufacturers not only contribute to the production of this robust material but also play a crucial role in innovation. They continually strive to improve the mesh's performance, introducing new alloys, coatings, and manufacturing techniques to enhance its properties. Some manufacturers even offer eco-friendly options, such as using recycled materials or developing meshes that are more sustainable over time.

The applications of diamond mesh are numerous and diverse. In construction, it serves as reinforcement in concrete structures, providing stability and strength. In agriculture, it's used for animal enclosures and crop protection. Mining industries utilize it for sieving and screening operations, while in filtration systems, it helps separate solids from liquids effectively.

In conclusion, the diamond mesh manufacturer is an integral part of the industrial supply chain. Their expertise, precision, and commitment to quality ensure that this versatile material continues to serve a multitude of purposes across various sectors. Whether it's reinforcing a towering skyscraper or protecting a delicate ecosystem, the diamond mesh, crafted diligently by these manufacturers, stands as a testament to human ingenuity and the power of engineering.

The final product can be customized to meet specific requirements, be it in terms of size, aperture, or material The final product can be customized to meet specific requirements, be it in terms of size, aperture, or material

The final product can be customized to meet specific requirements, be it in terms of size, aperture, or material The final product can be customized to meet specific requirements, be it in terms of size, aperture, or material diamond mesh manufacturer.

Diamond mesh manufacturers not only contribute to the production of this robust material but also play a crucial role in innovation. They continually strive to improve the mesh's performance, introducing new alloys, coatings, and manufacturing techniques to enhance its properties. Some manufacturers even offer eco-friendly options, such as using recycled materials or developing meshes that are more sustainable over time.

The applications of diamond mesh are numerous and diverse. In construction, it serves as reinforcement in concrete structures, providing stability and strength. In agriculture, it's used for animal enclosures and crop protection. Mining industries utilize it for sieving and screening operations, while in filtration systems, it helps separate solids from liquids effectively.

In conclusion, the diamond mesh manufacturer is an integral part of the industrial supply chain. Their expertise, precision, and commitment to quality ensure that this versatile material continues to serve a multitude of purposes across various sectors. Whether it's reinforcing a towering skyscraper or protecting a delicate ecosystem, the diamond mesh, crafted diligently by these manufacturers, stands as a testament to human ingenuity and the power of engineering.

diamond mesh manufacturer.

Diamond mesh manufacturers not only contribute to the production of this robust material but also play a crucial role in innovation. They continually strive to improve the mesh's performance, introducing new alloys, coatings, and manufacturing techniques to enhance its properties. Some manufacturers even offer eco-friendly options, such as using recycled materials or developing meshes that are more sustainable over time.

The applications of diamond mesh are numerous and diverse. In construction, it serves as reinforcement in concrete structures, providing stability and strength. In agriculture, it's used for animal enclosures and crop protection. Mining industries utilize it for sieving and screening operations, while in filtration systems, it helps separate solids from liquids effectively.

In conclusion, the diamond mesh manufacturer is an integral part of the industrial supply chain. Their expertise, precision, and commitment to quality ensure that this versatile material continues to serve a multitude of purposes across various sectors. Whether it's reinforcing a towering skyscraper or protecting a delicate ecosystem, the diamond mesh, crafted diligently by these manufacturers, stands as a testament to human ingenuity and the power of engineering. Latest news

-

Glass Jar with Wooden Screw Lid-Anping Puersen|Heat Resistant,BPA Free

NewsAug.16,2025

-

Glass Food Storage Jar with Screw Wooden Lid - Anping County Puersen | Heat Resistance, BPA Free

NewsAug.16,2025

-

High Borosilicate Glass Food Storage Jar with Wooden Screw Lid|Anping County Puersen Hardware Wire Mesh Products Co., Ltd

NewsAug.16,2025

-

Welded Wire Mesh for Industry Factory - Durable & Strong

NewsAug.16,2025

-

Glass Jar with Wooden Screw Lid - Anping County Puersen Hardware Wire Mesh Products Co.,Ltd|Durable, Eco-Friendly Food Storage

NewsAug.15,2025

-

Chain Link Fence - Anping County Puersen | Durable, Versatile Fencing

NewsAug.15,2025