Oct . 14, 2024 08:01 Back to list

deformed steel rebar manufacturers

Understanding Deformed Steel Rebar Manufacturers

In the construction industry, deformed steel rebar, commonly referred to as reinforcement bar, plays a vital role in providing the necessary tensile strength to concrete structures. Unlike smooth steel bars, deformed rebar has surface patterns that enhance the bond between the rebar and the concrete, ensuring greater structural integrity. This article explores the importance of deformed steel rebar manufacturers, the manufacturing process, and the key factors to consider when selecting a manufacturer.

The Role of Deformed Steel Rebar in Construction

Concrete, while strong in compression, is weak in tension. This is where rebar comes into play. Deformed steel rebar not only compensates for concrete's weakness but also enhances its durability. It is used in a variety of applications, from residential buildings to bridges and highways. The ribbed surface of deformed rebar significantly increases its adhesion to the surrounding concrete, preventing slippage under load and guaranteeing a stable structure.

Manufacturing Process of Deformed Steel Rebar

The production of deformed steel rebar involves several steps, ensuring that the final product meets the stringent quality standards required in construction.

1. Raw Material Selection The process begins with the selection of high-quality steel billets or rods. The quality of the raw material is paramount, as it directly affects the strength and durability of the final product.

2. Heating Steel billets are heated to a high temperature in a furnace. This heating process is essential for making the steel malleable enough to be shaped into rebar.

3. Rolling Once heated, the billets are passed through a series of rollers, which form them into designated sizes and shapes. During this stage, the distinctive deformations or ribs are created on the surface of the rebar.

4. Cooling After rolling, the rebar is rapidly cooled using water or air to harden it. This quenching process contributes to the final strength and hardness of the rebar.

5. Cutting and Testing The rebar is then cut to specific lengths based on market requirements. Quality control measures, including tensile strength tests and dimensional checks, are conducted to ensure that the rebar meets industry standards.

deformed steel rebar manufacturers

6. Packaging Finally, the finished rebar is bundled and prepared for shipment to construction sites or suppliers.

Choosing the Right Deformed Steel Rebar Manufacturer

Selecting a reliable manufacturer of deformed steel rebar is critical for construction projects. Here are some factors to consider

1. Quality Standards Look for manufacturers that adhere to established industry standards, such as ASTM (American Society for Testing and Materials) or ISO certifications. This ensures that the rebar meets required strength and durability criteria.

2. Production Capacity Depending on the scale of your project, it is essential to choose a manufacturer that can meet your volume requirements. Larger manufacturers often have the capacity to fulfill bulk orders more efficiently.

3. Technology and Equipment Investigate the technology and machinery used in the manufacturing process. Advanced equipment can lead to better precision and consistency in the quality of rebar produced.

4. Experience and Reputation Manufacturers with a long-standing presence in the market are typically more reliable. Research customer reviews and testimonials to gauge the reputation of potential suppliers.

5. Customer Service A good manufacturer should provide excellent customer service, including support throughout the purchasing process and after-sales services. This is especially important if you need assistance with custom orders or technical specifications.

6. Pricing While cost should not be the sole criterion for choosing a manufacturer, it is essential to balance quality with budget constraints. Obtain quotes from multiple suppliers and compare them to ensure that you are getting a competitive price without compromising on quality.

Conclusion

Deformed steel rebar is an essential component in modern construction, offering the necessary tension to complement the compression strength of concrete. Understanding the manufacturing process and knowing what to look for in a reliable manufacturer can greatly influence the success of construction projects. By taking into account quality standards, production capacity, technology, reputation, customer service, and pricing, builders and contractors can choose a rebar manufacturer that meets their needs and contributes to the strength and longevity of their structures.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

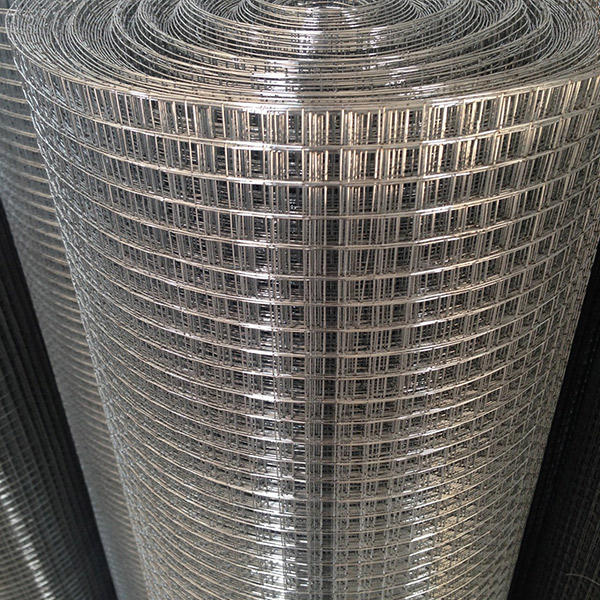

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025