Aug . 15, 2024 02:02 Back to list

Customized Welded Wire Mesh Dimensions for Reinforcing Concrete Structures and Construction Applications

The Importance of OEM Welded Wire Mesh Sizes for Concrete

In the realm of construction and structural engineering, welded wire mesh plays a pivotal role in enhancing the integrity and durability of concrete structures. Made from crossing and welding steel wires at various intervals, welded wire mesh provides essential reinforcement to concrete, making it a preferred choice among builders and engineers alike. Understanding the specific OEM (Original Equipment Manufacturer) welded wire mesh sizes for concrete applications can significantly influence both the performance and longevity of a structure.

Why Welded Wire Mesh?

The primary function of welded wire mesh in concrete is to distribute tensile stress, which concrete is not naturally good at handling. Concrete typically exhibits high compressive strength but is comparatively weak in tension. By incorporating welded wire mesh, builders can ensure that the concrete will resist cracking and other forms of structural failure under tensile loads. This is particularly important in applications such as sidewalks, driveways, slabs, and walls, where stress distribution is crucial.

OEM Specifications The Key to Success

When it comes to selecting the appropriate welded wire mesh for concrete applications, understanding OEM specifications becomes essential. OEM manufacturers provide welded wire mesh in various sizes, wire gauges, and spacing options to suit different project needs. These specifications often dictate the mesh’s capability to handle specific load requirements, making it vital to choose the right size and type for any structural project.

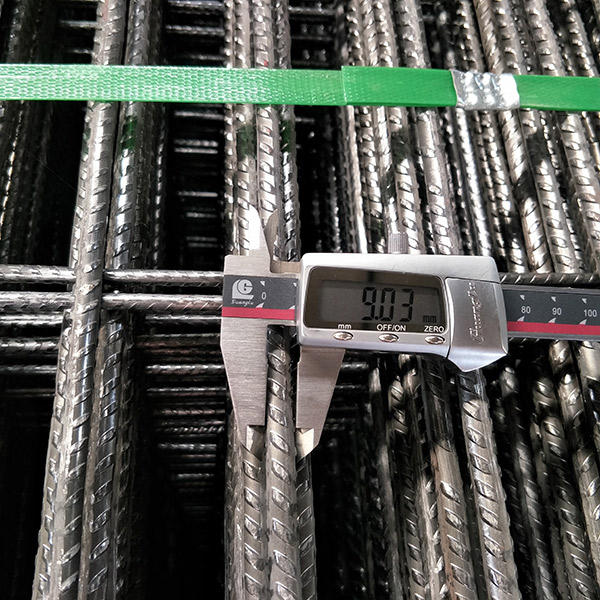

The wire diameter and spacing are two critical factors. Generally, the wire diameter can range anywhere from 2.5 mm to 6 mm, while the spacing may vary between 100 mm and 300 mm. For instance, in heavier structural applications, a thicker wire with tighter spacing may be required to provide additional reinforcement. Conversely, lighter applications, such as residential driveways, may be adequately served with thinner wire and wider spacing.

oem welded wire mesh sizes for concrete

Installing Welded Wire Mesh in Concrete

Proper installation of welded wire mesh is as crucial as selecting the right type. Typically, the mesh should be positioned in the middle of the concrete slab to maximize its effectiveness. It’s essential to ensure that the mesh does not rest on the ground; spacing supports or chairs can be utilized to keep it suspended, allowing the concrete to encase the mesh adequately. This placement improves the bond between the mesh and the concrete, thereby enhancing structural integrity.

Long-Term Benefits

Investing in the correct OEM welded wire mesh sizes not only improves structural performance but also contributes to the longevity of concrete elements. Structures reinforced with adequately sized mesh can withstand environmental factors such as temperature fluctuations, moisture, and heavy loads without deteriorating. Additionally, this reinforcement reduces the likelihood of repairs due to cracking or settling, ultimately saving on long-term maintenance costs.

Conclusion

In summary, OEM welded wire mesh sizes are a crucial consideration for anyone involved in concrete construction. By ensuring that the right specifications are selected, builders can significantly enhance the strength and durability of their projects. With its capacity to distribute tensile forces effectively, welded wire mesh serves as a fundamental component in modern construction, enabling the creation of robust structures designed to endure the test of time. As the construction industry continues to innovate, the importance of understanding and utilizing the appropriate welded wire mesh will remain paramount for structural integrity and safety.

-

Chain Link Fence - Anping County Puersen | Durable, Versatile Fencing

NewsAug.15,2025

-

Chain Link Fence-Galvanized Steel Fence Factory|Durable Security&Wire Mesh

NewsAug.15,2025

-

Chain Link Fence: Durable & Versatile Security Solution | Anping County Puersen Hardware Wire Mesh Products Co., Ltd.

NewsAug.15,2025

-

Chain Link Fence-Durable&Versatile|Anping County Puersen

NewsAug.15,2025

-

Welded Wire Mesh for Industry: Factory Supplier of Quality Mesh

NewsAug.15,2025

-

Chain Link Fence - Anping County Puersen Hardware Wire Mesh Products Co., Ltd.|Durable, Versatile, Reliable Fencing Solution

NewsAug.14,2025