Aug . 02, 2024 14:47 Back to list

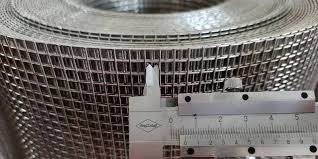

Custom Galvanized Iron Welded Wire Mesh for Various Applications and Durability Needs

Understanding OEM Galvanized Iron Welded Wire Mesh Features, Applications, and Benefits

In today's fast-paced industrial world, the demand for versatile and durable materials is ever-growing. One such material that has carved a niche for itself across various sectors is the OEM galvanized iron welded wire mesh. This product has become a staple in construction, agriculture, and various manufacturing processes due to its robust characteristics and adaptability.

What is Galvanized Wire Mesh?

Galvanized wire mesh is a type of fencing material made from iron wires that are welded together to form a mesh pattern. The term galvanized refers to the coating of zinc that is applied to the iron, which provides corrosion resistance and extends the lifespan of the product. The high-quality OEM (Original Equipment Manufacturer) galvanized wire mesh is designed to meet specific client requirements and often adheres to stringent quality standards.

Key Features of OEM Galvanized Iron Welded Wire Mesh

1. Corrosion Resistance One of the primary advantages of galvanized wire mesh is its enhanced resistance to rust and corrosion, which is achieved through the zinc coating. This feature makes it ideal for outdoor applications where it may be exposed to moisture and varying weather conditions.

2. Durability The welded construction of the mesh ensures that it can withstand heavy loads and impact, making it suitable for various applications, from industrial settings to agricultural use.

3. Versatile Applications OEM galvanized iron welded wire mesh can be used in a multitude of applications, including security fencing, animal enclosures, and as a reinforcement material in concrete structures. Its versatility allows it to cater to different industries and meet various needs.

4. Customizability As an OEM product, galvanized wire mesh can be tailored to specific dimensions, wire gauges, and mesh sizes, allowing businesses to specify the product that best fits their requirements. This customization enhances the material’s usability across different projects.

Applications of OEM Galvanized Wire Mesh

oem galvanized iron welded wire mesh

1. Construction In the construction industry, welded wire mesh is commonly used to reinforce concrete. It provides strength and stability, ensuring that structures can withstand physical stress and environmental factors.

2. Agriculture Farmers utilize galvanized wire mesh to create fences for livestock, protective barriers for crops, and even as support for climbing plants. Its durability helps to ensure the safety and productivity of agricultural operations.

3. Security Many businesses and residential properties employ welded wire mesh as a security fence to deter intruders. Its robust design effectively provides a physical barrier, often combined with added security measures like barbed wire or electrical fencing.

4. Manufacturing In manufacturing environments, the wire mesh can be used to create storage cages, shelving units, and safety barriers around machinery, enhancing safety and organization on the production floor.

Benefits of Using OEM Galvanized Iron Welded Wire Mesh

- Cost-Effectiveness While the initial investment may be higher compared to non-galvanized options, the long lifespan and reduced need for maintenance make it a more cost-effective solution in the long run.

- Aesthetic Appeal The uniform appearance of welded wire mesh provides a clean, professional look that can be attractive for various applications, including decorative fencing.

- Ease of Installation This type of wire mesh is relatively easy to install, which can save time and labor costs during deployment.

In conclusion, OEM galvanized iron welded wire mesh is an exceptional material that combines strength, versatility, and longevity, making it suitable for a wide array of applications in different industries. Its excellent corrosion resistance and customization options further enhance its appeal, making it a preferred choice for businesses looking to invest in reliable and durable materials. Whether for construction, agriculture, security, or manufacturing, this robust product continues to meet the diverse needs of modern industries.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025