Nov . 07, 2024 13:27 Back to list

Innovative Steel Grating Solutions with Cross Twisted Bars for Enhanced Strength and Durability

The Cross Twisted Bar A Key Component in Steel Grating Manufacturing

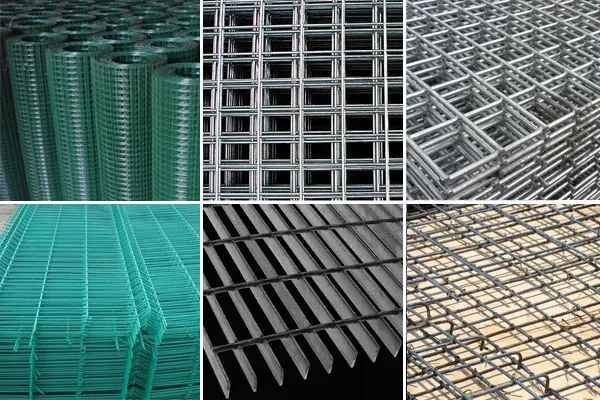

In the world of industrial flooring systems, the integrity and safety of walkways, platforms, and various structures depend heavily on the quality of materials used. Among these materials, steel grating has emerged as a preferred choice due to its robust characteristics and versatility. One of the critical components in the production of steel grating is the cross twisted bar, a feature that enhances both performance and durability. This article explores the significance of the cross twisted bar in steel grating manufacturing, its benefits, and its applications.

Understanding Cross Twisted Bars

Cross twisted bars are specifically designed steel bars that are twisted at intervals to improve grip and stability. When used in steel grating, the twisted configuration creates a unique structural support that allows for greater load-bearing capacity while maintaining a lightweight design. This combination of strength and efficiency is especially important in environments where foot traffic and heavy machinery operate simultaneously.

Benefits of Cross Twisted Bars

1. Increased Traction One of the most notable advantages of cross twisted bars is the enhanced traction they provide. The twisting action creates protrusions on the surface of the grating, which significantly reduces the risk of slipping, making it an ideal choice for industrial applications where safety is paramount. This feature is particularly beneficial in wet or oily conditions common in manufacturing facilities and outdoor environments.

2. Load Distribution The twisted design of these bars allows for even distribution of loads across the grating surface. This is crucial in preventing localized stress points that could lead to deformation or failure. As a result, structures fitted with steel grating featuring cross twisted bars can support heavier loads, increasing their longevity and reliability.

3. Corrosion Resistance Steel grating is often exposed to harsh environmental conditions, which can lead to corrosion over time. Manufacturers can enhance the durability of cross twisted bars by using galvanization or other protective coatings. This treatment not only extends the lifespan of the grating but also ensures consistent performance in various industries, including chemical processing, oil and gas, and wastewater treatment.

4. Aesthetic Appeal While functionality is vital, the aesthetic aspect of industrial flooring should not be overlooked. Cross twisted bars can be incorporated into designs that blend well with contemporary architectural styles. Various finishes and coatings are available, allowing for customization that meets both safety and aesthetic requirements.

cross twisted bar for steel grating manufacturer

Applications of Steel Grating with Cross Twisted Bars

The versatility of steel grating with cross twisted bars is evident in its wide range of applications across different sectors. Common uses include

- Walkways and Platforms In factories and warehouses, these gratings provide safe walking surfaces slightly elevated from the ground, ensuring that debris and liquids can flow through without obstructing foot traffic.

- Stair Treads Cross twisted bars enhance the safety of stairs used in industrial settings, reducing the risk of accidents and injuries.

- Drain Covers In municipal areas, steel gratings are often used for sewage and drainage access points, allowing for maintenance while ensuring that the surfaces remain safe for pedestrians.

- Maintenance Workers In industries that require regular inspection and maintenance, the combination of strength and slip resistance in cross twisted bar gratings makes it easier for workers to navigate equipment and machinery.

Conclusion

As industries continue to evolve, the need for reliable and safe flooring solutions remains critical. The cross twisted bar plays a vital role in steel grating manufacturing, contributing to its strength, safety, and versatility. With its numerous advantages, it's no wonder that steel grating with cross twisted bars is a go-to solution for various applications. As manufacturers seek to develop more innovative and durable products, the importance of features like the cross twisted bar will continue to grow, ensuring that industries around the globe remain safe and efficient in their operations.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025