Nov . 28, 2024 14:08 Back to list

Manufacturers of Reinforced Concrete Steel Welded Wire Mesh Products and Solutions

Understanding Concrete Steel Welded Wire Reinforcing Mesh Factories

Concrete has long been a foundation stone in construction, providing strength and durability for various structures, from residential buildings to massive bridges. While concrete is powerful in compression, it is relatively weak in tension. To address this limitation, the construction industry often turns to steel reinforcement, specifically welded wire mesh. This article delves into what concrete steel welded wire reinforcing mesh is, its manufacturing process, and the role of factories in producing this essential construction material.

What is Welded Wire Reinforcing Mesh?

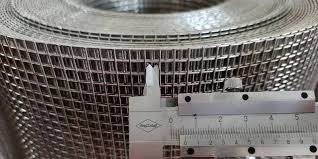

Welded wire reinforcing mesh consists of steel wires that are intersected and welded together to form a grid-like structure. This mesh is embedded in concrete to enhance tensile strength and prevent cracking. The mesh is typically made from high-strength carbon steel wires, which are resistant to deformation. Its applications range widely, encompassing floors, walls, pavements, and even precast concrete products.

The Manufacturing Process

The production of welded wire reinforcing mesh is a meticulous and technical process. It begins with the selection of high-quality steel wires, which are drawn and treated to achieve the desired mechanical properties. The wires are then cut to specific lengths and arranged in a grid format.

The next step involves the welding process, where the intersection points of the grid are welded together using electric resistance welding. This method ensures that the mesh is not only strong but also uniform in consistency. After welding, the mesh undergoes a series of inspections to guarantee that it meets industry standards for strength, durability, and dimensional accuracy.

concrete steel welded wire reinforcing mesh factories

Once the quality checks are complete, the welded wire mesh is either shipped in flat sheets or rolled up, depending on the client’s requirements. Additional treatments such as galvanization or coating can be applied to enhance corrosion resistance, particularly for projects exposed to harsh environmental conditions.

The Role of Factories

Concrete steel welded wire reinforcing mesh factories play a crucial role in the construction supply chain. They are equipped with advanced machinery that streamline the production process, ensuring efficiency and precision. Factories must adhere to strict safety and quality regulations, which not only bolster their reputation but also ensure the safety of the structures built with their materials.

Moreover, factories can cater to specific client needs by producing customized wire mesh designs. Whether it’s varying wire diameters, mesh sizes, or additional treatment options, these flexible capabilities provide engineers and builders with the tools they need to meet the unique requirements of their projects.

The Importance of Quality

Investing in high-quality welded wire reinforcing mesh is paramount for the integrity and longevity of construction projects. Poor-quality mesh can lead to premature structural failures, incurring costly repairs and endangering safety. Thus, selecting a reliable factory becomes essential, as their commitment to quality directly influences the overall success of the construction.

In conclusion, concrete steel welded wire reinforcing mesh is a vital component of modern construction, providing the necessary support and stability required for durable structures. Factories specializing in this product not only contribute to the efficiency of the production process but also ensure that builders have access to high-quality materials essential for their projects. As the construction industry continues to evolve, the importance of robust and reliable reinforcing materials will only increase, making the role of these factories more crucial than ever.

-

Hot Dipped Galvanized Steel Grating Durable & Corrosion-Resistant Solutions

NewsMay.31,2025

-

Plastic-Coated Hexagonal Wire Mesh Manufacturer Durable Solutions

NewsMay.31,2025

-

Reinforced Concrete Expanded Metal Mesh Suppliers & Factories High-Strength

NewsMay.31,2025

-

Galvanized Steel Wire High-Strength, Rustproof Material & Suppliers

NewsMay.30,2025

-

1 Inch Hexagonal Wire Mesh Heavy-Duty Factories & Suppliers

NewsMay.30,2025

-

Green PVC Coated Wire Durable, Weather-Resistant Electrical Solutions

NewsMay.30,2025