Oct . 22, 2024 09:39 Back to list

Manufacturers of Welded Wire Mesh for Concrete Reinforcement Solutions

The Importance of Concrete Reinforcing Roll Welded Wire Mesh in Construction

In the world of construction, the integrity and durability of structures are paramount. One of the essential materials that contribute significantly to this facet is concrete reinforcing roll welded wire mesh. This product has gained prominence among manufacturers and builders due to its various advantages, ensuring that constructions withstand the test of time and environmental pressures.

Understanding Roll Welded Wire Mesh

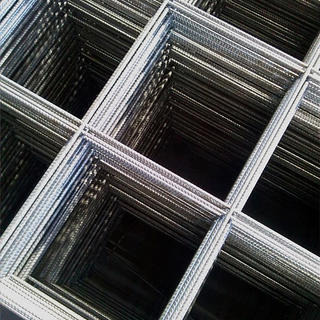

Concrete reinforcing roll welded wire mesh is a mesh sheet made from high-quality steel wires that are welded together at their intersections. The term roll refers to how this mesh is manufactured and packaged, allowing it to be rolled out easily for construction purposes. The primary function of this mesh is to enhance the tensile strength of concrete, distributing loads more evenly and reducing the chances of cracks and other structural failures.

Primary Applications

The applications of concrete reinforcing roll welded wire mesh are diverse, making it suitable for various construction projects, such as

1. Road Construction Used to reinforce pavements and roadways, providing added durability against traffic and environmental stressors. 2. Floor Slabs Offers solid support in residential and commercial buildings, improving the lifespan of floors by preventing cracking and sagging.

3. Walls and Foundations Essential for ensuring stability, especially in areas with expansive soil or seismic activity, where additional structural support is necessary.

4. Precast Concrete Products Integral in the manufacturing of precast elements like beams and slabs, which require reliable tensile support.

Benefits of Using Roll Welded Wire Mesh

concrete reinforcing roll welded wire mesh manufacturers

Manufactured by countless reliable companies, roll welded wire mesh brings several benefits to construction projects

1. Enhanced Strength The welded configuration allows for superior tensile strength, crucial for reinforcing concrete under stress.

2. Cost-Effectiveness Using this mesh can lower the overall costs associated with construction by reducing the need for additional reinforcement materials.

3. Ease of Installation Because it comes in rolls, this mesh is easy to transport and install, making it a favorite among contractors striving for efficiency on-site.

4. Reduction of Cracking The mesh effectively controls the cracking of concrete, a common issue that can lead to significant repair costs if not adequately managed.

5. Longevity and Durability Structures reinforced with this mesh tend to last longer, requiring fewer repairs over time, fostering a strong return on investment.

Choosing the Right Manufacturer

Selecting a reliable manufacturer for concrete reinforcing roll welded wire mesh is crucial. Builders should look for companies that adhere to industry standards and utilize high-quality materials. Additionally, manufacturers should be able to provide certifications that guarantee the performance and safety of their products. Engaging with manufacturers who offer customization options can also be beneficial, as specific projects may have unique requirements.

Conclusion

In summary, concrete reinforcing roll welded wire mesh is an invaluable component in the construction industry. Its ability to enhance the structural integrity of concrete while offering cost savings and ease of installation makes it a popular choice among builders and manufacturers alike. As the demand for durable construction materials continues to grow, investing in high-quality roll welded wire mesh will remain essential in achieving long-lasting and robust structures. Whether for commercial or residential construction, this material is a cornerstone in modern building practices, ensuring safety, stability, and sustainability in the built environment.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025