Dec . 06, 2024 03:53 Back to list

Factors Influencing Production of Welded Wire Mesh for Concrete Reinforcement

The Importance of Reinforcing Roll Welded Wire Mesh in Concrete Construction

Concrete is one of the most widely used construction materials in the world. Its strength, durability, and versatility make it an ideal choice for various applications, from residential buildings to large infrastructure projects. However, to enhance the tensile strength and overall performance of concrete structures, reinforcing materials are essential. One of the most effective solutions is the use of roll welded wire mesh, a product manufactured by specialized factories dedicated to this important component of modern construction.

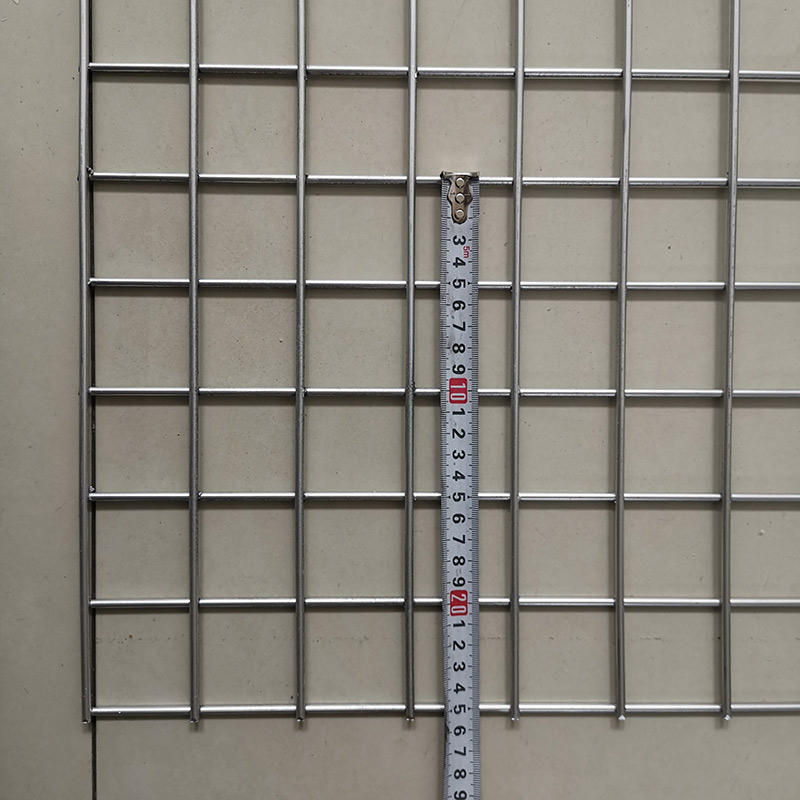

Roll welded wire mesh consists of a series of steel wires that are welded together at regular intervals, forming a strong and stable grid. This mesh can be rolled for easy transport and installation, making it a practical choice for construction sites. The production of this essential material is carried out in advanced factories that prioritize quality and efficiency.

Manufacturing Process

The manufacturing process of roll welded wire mesh typically involves several key steps. It begins with the selection of high-quality steel wire, which is then processed through a series of precise machinery. The wires are cut to specific lengths and fed into welding machines that join them at predetermined points. This process ensures that the mesh maintains its structural integrity while allowing for maximum flexibility in application.

After welding, the mesh is subjected to quality control checks to ensure it meets industry standards. Factors such as weld strength, wire diameter, and spacing between wires are all critical to the performance of the final product. Factories often utilize advanced technology to monitor these parameters, ensuring that the mesh produced is reliable and durable.

Applications in Concrete Construction

concrete reinforcing roll welded wire mesh factories

Roll welded wire mesh is widely used in concrete construction for various reasons. One of the primary benefits is its ability to distribute loads evenly throughout the concrete slab or structure. When embedded within concrete, this mesh helps to resist cracking and deformation by providing additional tensile strength. As a result, structures that utilize welded wire mesh are often more durable and capable of withstanding the stresses of environmental factors and load-bearing situations.

In residential construction, roll welded wire mesh is often employed in foundation slabs, driveways, and flooring systems. It helps reinforce these areas, reducing the likelihood of cracks and improving the longevity of the construction. In commercial and industrial applications, this material is indispensable for larger-scale projects, such as parking lots, sidewalks, and bridge decks, where heavy loads and significant traffic can cause considerable stress.

Advantages of Using Roll Welded Wire Mesh

The advantages of using roll welded wire mesh extend beyond its structural benefits. The ease of installation is another significant factor that contributes to its popularity. Because it is available in roll form, contractors can quickly lay out the mesh on-site, speeding up the overall construction process. This efficiency not only saves time but also reduces labor costs, making it a cost-effective solution for many projects.

Moreover, the durability of roll welded wire mesh ensures that it remains effective over time, even in harsh conditions. It is resistant to corrosion when properly coated, and its strength provides long-term support to concrete structures, reducing the need for frequent repairs and maintenance.

Conclusion

As the construction industry continues to evolve, the importance of high-quality reinforcing materials like roll welded wire mesh cannot be overstated. The factories that produce this essential component play a crucial role in ensuring that it meets the rigorous demands of modern construction. By incorporating roll welded wire mesh into concrete applications, builders can enhance the longevity and safety of their projects, ultimately contributing to the overall quality of the built environment.

-

Web Scraping-NIST|Data Extraction&Automation

NewsJul.21,2025

-

Galvanized Steel Chain Link Fence - Anping County Puersen|Durable Security Solution&Cost-Effective Fencing

NewsJul.21,2025

-

Galvanized Steel Chain Link Fence - Anping County Puersen Hardware Wire Mesh Products Co.,Ltd

NewsJul.21,2025

-

Galvanized Steel Chain Link Fences-Anping County Puersen Hardware Wire Mesh Products Co.,Ltd|Durable Corrosion-Resistant Fencing&Cost-Effective Security Solutions

NewsJul.21,2025

-

Diamond Steel Grating - Anping County Puersen Hardware Wire Mesh Products Co., Ltd.|Durable Industrial Solutions&Customized Steel Grating

NewsJul.21,2025

-

Galvanized Welded Wire Panel - Anping County Puersen | Corrosion Resistance&Industrial Use

NewsJul.21,2025