Nov . 25, 2024 15:05 Back to list

concrete block mesh factory

The Concrete Block Mesh Factory An Overview of Innovations and Processes

Concrete block mesh factories play a pivotal role in the construction industry, producing essential materials that form the backbone of modern infrastructure. These factories specialize in manufacturing concrete blocks reinforced with mesh, enhancing the blocks' strength, durability, and resilience. This article provides an in-depth look at the processes, innovations, and significance of concrete block mesh production.

The Importance of Concrete Block Mesh

Concrete block mesh is critical in various construction applications. The reinforcements provided by mesh significantly enhance the tensile strength of concrete blocks, making them less prone to cracking and structural failures. Furthermore, these blocks are used in a wide array of settings, from residential housing to commercial buildings, retaining walls, and roadways. The versatility and robustness of concrete block mesh have made it a favored choice among builders and architects.

Manufacturing Process

The production of concrete blocks with mesh involves several meticulous steps. First, high-quality raw materials, including cement, aggregates, and water, are sourced. The exact proportions must be calculated to ensure the resulting concrete mix possesses the desired strength and consistency.

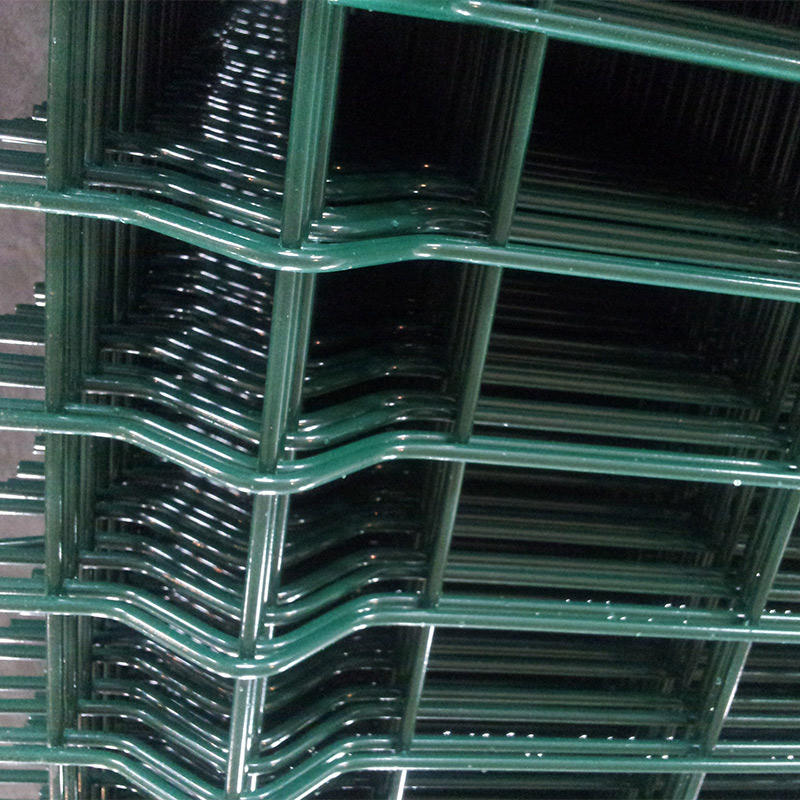

Once the mix is prepared, it is poured into block molds. This is where the magic of mesh comes into play. Reinforcing mesh is strategically placed within the mold before the concrete is poured in. The mesh could be made from various materials, such as steel or fiberglass, depending on the specific requirements of the project. Once the concrete sets, the blocks are demolded and undergo a curing process, which further strengthens the blocks and ensures their durability.

Innovations in Concrete Block Mesh Production

concrete block mesh factory

In recent years, several innovations have transformed the concrete block mesh industry. Advanced manufacturing technologies, such as automated production lines and robotics, have improved efficiency and precision in the manufacturing process. These technological advancements not only reduce labor costs but also enhance the consistency and quality of the finished products.

Furthermore, sustainability has become a focal point in the concrete industry. Many factories are now exploring the use of recycled materials in their production processes, reducing waste and the environmental impact associated with concrete production. Innovations like incorporating industrial byproducts into the concrete mix are gaining popularity, leading to greener building solutions.

Quality Control and Testing

Ensuring the quality of concrete block mesh is essential for safety and durability. Factories employ rigorous quality control measures throughout the production process. This includes testing the raw materials for compliance with industry standards and conducting strength tests on the finished blocks. These tests assess the compressive, tensile, and flexural strength of the blocks, ensuring they meet or exceed the required specifications.

Regular inspections and maintenance of machinery also play a crucial role in maintaining consistent production quality. With a robust quality management system in place, factories can deliver reliable products that builders trust.

Conclusion

The concrete block mesh factory stands at the intersection of tradition and innovation within the construction sector. By producing reinforced concrete blocks that are essential for modern building needs, these factories contribute significantly to architectural advancements and infrastructure development. As the industry continues to evolve with new technologies and sustainable practices, the future looks promising for concrete block mesh production. As we aim for more resilient and eco-friendly construction solutions, the role of these factories will undoubtedly become increasingly vital.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025