Nov . 15, 2024 17:21 Back to list

concrete block mesh factories

Understanding Concrete Block Mesh Factories

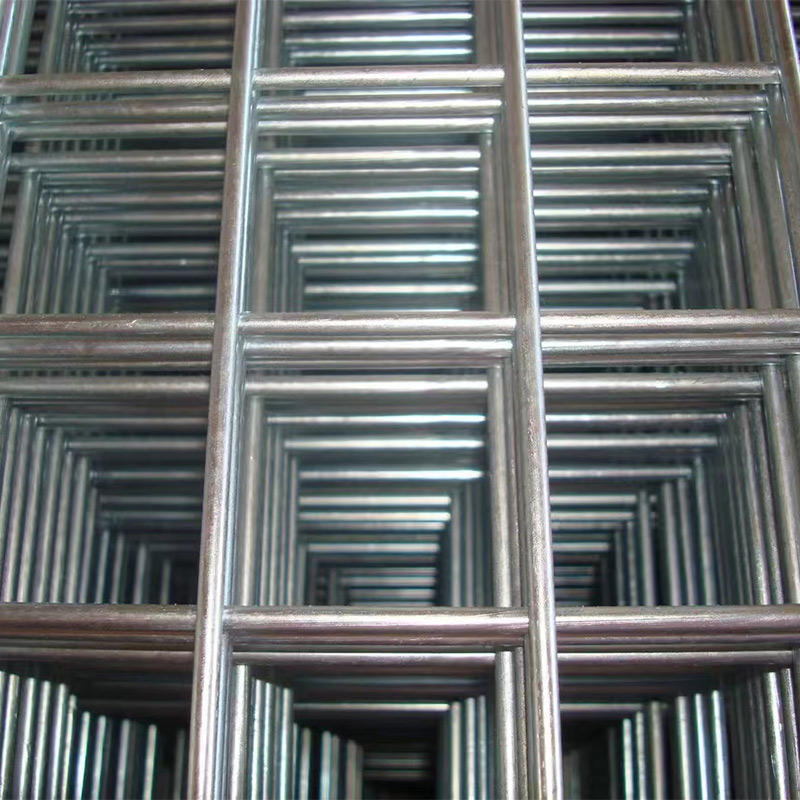

In the ever-evolving construction industry, concrete block mesh factories play a critical role in enhancing the efficiency and sustainability of building materials. These factories specialize in producing concrete blocks that have embedded steel mesh, which significantly improves their structural integrity and load-bearing capacity. As demand for durable construction materials continues to rise, understanding the operations, benefits, and innovations within these factories becomes essential.

Concrete blocks are celebrated for their versatility, strength, and cost-effectiveness. When combined with steel mesh, these blocks offer enhanced performance, making them ideal for various construction applications, from residential buildings to large commercial structures. The integration of steel mesh provides additional tensile strength, reducing the risk of cracking and allowing for safer and more resilient construction. This is particularly beneficial in areas prone to seismic activity, where buildings must withstand dynamic forces.

The manufacturing process in concrete block mesh factories involves several key stages. First, raw materials such as cement, aggregates, and water are combined in precise ratios to create the concrete mix. Next, the mix is poured into molds, and steel mesh is positioned strategically within the mold before the concrete sets. After the concrete cures, the molds are removed, revealing sturdy blocks ready for use. This process can be automated for efficiency, allowing factories to scale production and meet increasing market demands.

concrete block mesh factories

Environmental sustainability is another significant factor driving innovations in concrete block mesh factories. Many factories are adopting eco-friendly practices by utilizing recycled materials in their mixes, reducing waste, and implementing energy-efficient production techniques. Additionally, the use of concrete blocks with steel mesh can lead to lighter structures, reducing the overall carbon footprint of construction projects. This aligns well with global efforts to promote sustainable building practices and reduce greenhouse gas emissions.

As technology continues to advance, concrete block mesh factories are integrating cutting-edge machinery and software to streamline operations. Automation and robotics help reduce labor costs and increase precision in manufacturing, resulting in higher-quality products. Furthermore, software solutions allow for better inventory management, real-time monitoring of production processes, and data analysis to optimize efficiency. These innovations not only elevate the quality of the concrete blocks produced but also enhance overall productivity within the factory.

In conclusion, concrete block mesh factories are pivotal in meeting the demands of modern construction by providing robust and durable building materials. Their processes contribute to the resilience of structures while promoting sustainability through eco-friendly practices. As technology progresses, these factories are poised to become even more efficient and innovative, shaping the future of the construction industry. Investing in this sector not only supports economic growth but also fosters advancements that contribute to creating safer and more sustainable communities. Understanding the dynamics of these factories will undoubtedly inform future developments in construction methodologies and materials, paving the way for a more resilient built environment.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025