Jul . 28, 2024 10:00 Back to list

Comparative Analysis of Prices from Barbed Wire Manufacturers for Various Sizes and Specifications

Understanding 1.6mm, 2.0mm, and 2.4mm Barbed Wire Prices from Manufacturers

Barbed wire has long been an essential material in various industries, including agriculture, construction, and security. It serves multiple purposes, such as fencing cattle, protecting properties, and ensuring safety. The diameter of the wire and the spacing of the barbs play significant roles in its effectiveness. Among the different specifications available, 1.6mm, 2.0mm, and 2.4mm barbed wire are commonly sought after.

Overview of Barbed Wire Types

1. 1.6mm Barbed Wire This thinner gauge is often preferred for light-duty fencing applications. It provides adequate security while being relatively light and easy to handle. Farmers may use 1.6mm barbed wire to keep livestock in designated areas without overwhelming them with a very strong barrier. Additionally, it's often more cost-effective than thicker wires, which can appeal to budget-conscious buyers.

2. 2.0mm Barbed Wire The 2.0mm variant strikes a balance between strength and manageability. It's commonly used for medium-security needs. This gauge can withstand moderate pressure and is suitable for a range of applications, including residential property fencing and even some commercial usages. Manufacturers often recommend this thickness for users looking for reliability without the bulk and installation challenges that come with heavier wires.

3. 2.4mm Barbed Wire The 2.4mm barbed wire is robust and often used in high-security installations, such as prisons, military bases, and industrial properties. Its thicker gauge means it can withstand more force and deter unauthorized access effectively. While more expensive than the thinner options, its durability and efficiency in protecting valuable assets make it a preferred choice for those who require stronger fencing solutions.

Factors Influencing Barbed Wire Pricing

The prices for 1.6mm, 2.0mm, and 2.4mm barbed wire can vary significantly based on several factors

1.6mm 2mm 2.4mm barbed wire price manufacturers

1. Raw Material Costs The price of raw materials, such as steel, directly affects the cost of barbed wire. Fluctuations in the global steel market can lead to changes in pricing for manufacturers and subsequently for consumers.

2. Manufacturing Processes Different manufacturers have varying production techniques and operational costs. Companies using advanced technologies may brand their products as premium offerings, while others may focus on cost-efficiency.

3. Economies of Scale Larger manufacturers often benefit from economies of scale, allowing them to offer lower prices on higher volumes. Smaller producers may have to charge more due to lower production levels.

4. Coating and Treatment Barbed wire that is galvanized or coated to prevent rust and corrosion typically comes at a higher price. Consumers often weigh the long-term benefits of such materials against initial costs.

5. Market Demand Demand fluctuations can impact pricing. In times of high demand, prices may spike, while in periods of lower interest, discounts may be offered to encourage sales.

Conclusion

When considering the purchase of 1.6mm, 2.0mm, or 2.4mm barbed wire, understanding the specific needs of the application is crucial. Each gauge serves distinct purposes, and pricing can vary based on multiple factors. Manufacturers play a key role in determining prices, and it is wise for buyers to compare offerings from multiple sources. By doing thorough research and considering quality, gauge, and cost, buyers can make informed decisions that meet their fencing needs effectively.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

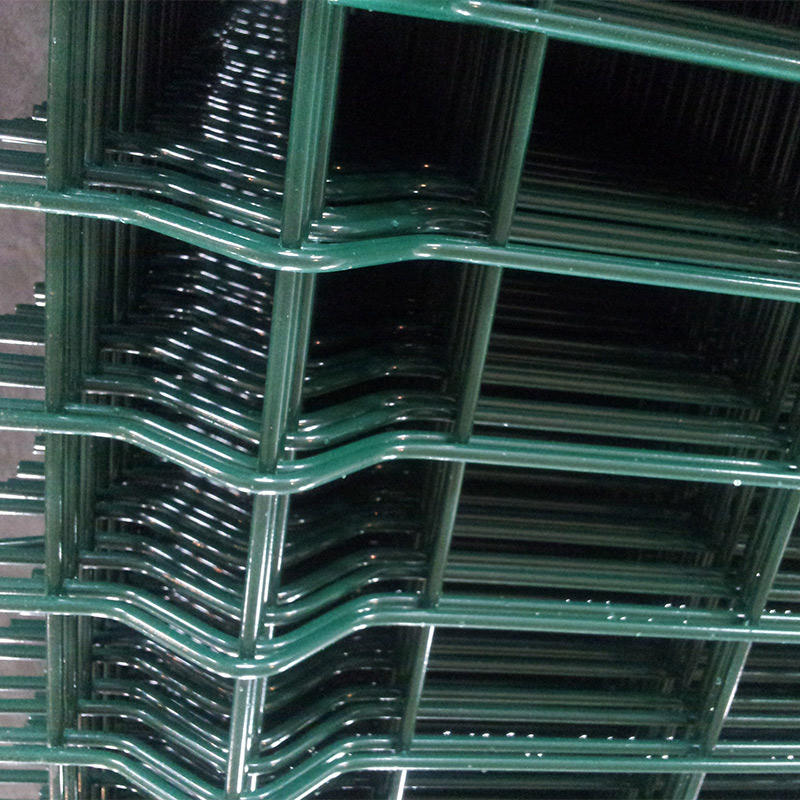

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025