Dec . 12, 2024 06:00 Back to list

cold rolled steel bar suppliers

Selecting the Right Cold Rolled Steel Bar Suppliers A Comprehensive Guide

In the manufacturing and construction industries, cold rolled steel bars are crucial materials due to their durability, strength, and versatility. When it comes to sourcing these essential components, the choice of suppliers can significantly influence the quality of the end product as well as the efficiency of the supply chain. This article explores the critical factors to consider when selecting cold rolled steel bar suppliers, emphasizing reliability, quality control, and customer service.

Understanding Cold Rolled Steel Bars

Cold rolled steel bars are produced by rolling steel at room temperature, which enhances their strength and allows for greater precision in dimensions and surface finish compared to hot rolled steel. This process results in a material that is ideal for various applications, ranging from construction beams to automotive parts. The unique properties of cold rolled steel, such as improved mechanical properties and a smoother surface finish, make it a preferred choice for industries that require high-quality steel components.

Factors to Consider When Choosing Suppliers

The foremost consideration when selecting a cold rolled steel bar supplier is the quality of their products. Reliable suppliers often have rigorous quality control measures in place, ensuring that their steel bars meet industry standards and specifications. Look for suppliers that provide certifications, such as ISO 9001, which demonstrates their commitment to quality management practices. Additionally, inquire about their testing procedures, which may include tensile strength tests, dimensional inspections, and surface quality assessments.

2. Material Specifications

Different applications require various grades and specifications of cold rolled steel. Before choosing a supplier, you should clearly understand your material requirements, including dimensions, grade, and tensile strength. A competent supplier will be able to provide a range of options that meet your specific needs and offer guidance on the best materials for your applications.

3. Production Capacity and Lead Times

Supply chain efficiency is crucial in maintaining project timelines. When evaluating suppliers, consider their production capacity and lead times. Suppliers that can handle large orders and respond swiftly to rush requests can be invaluable, particularly in industries with tight schedules. Discuss your project timelines with potential suppliers to ensure they can meet your delivery requirements.

cold rolled steel bar suppliers

4. Experience and Reputation

An established supplier will have a proven track record and a solid reputation within the industry. Conduct thorough research by reading customer reviews, requesting references, and analyzing case studies of previous supply partnerships. A supplier with extensive experience in providing cold rolled steel bars can offer insights and solutions that new entrants may lack.

5. Customer Service and Support

Effective communication and excellent customer service are essential in supplier relationships. Evaluate how responsive potential suppliers are to inquiries and whether they are willing to provide technical support. Good suppliers will not only fulfill orders but also assist with any issues that may arise during the procurement process.

6. Pricing and Payment Terms

While quality should take precedence over cost, it's essential to find a supplier that offers competitive pricing. Be cautious of suppliers that provide significantly lower prices, as this can sometimes indicate inferior quality. Additionally, evaluate their payment terms and flexibility, as this can impact cash flow and financial planning for your business.

7. Sustainability Practices

In today’s market, sustainability is becoming increasingly important. Consider suppliers who prioritize environmentally friendly practices, such as using recycled materials or implementing energy-efficient production processes. Partnering with eco-conscious suppliers can enhance your brand’s image and appeal to environmentally aware customers.

Conclusion

Choosing the right supplier for cold rolled steel bars is a pivotal decision that can impact your project outcomes and overall business success. By focusing on quality assurance, material specifications, production capabilities, reputation, customer service, pricing, and sustainability, you can make an informed decision that not only meets your immediate needs but also fosters long-term partnerships. Explore multiple options, ask relevant questions, and ultimately select a supplier that aligns with your business goals and values. The right supplier will not only provide you with high-quality materials but also contribute to the overall efficiency and success of your projects.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

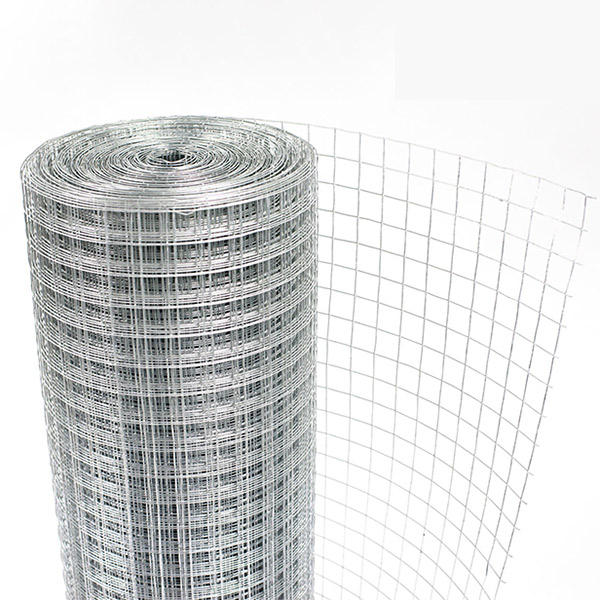

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025