Oct . 03, 2024 10:16 Back to list

Cold Rolled Steel Bar Manufacturing Process and Quality Control Techniques

The Dynamics of a Cold Rolled Steel Bar Factory

Cold rolled steel bars are critical components in various industries, including construction, automotive, and manufacturing. The manufacturing process for these bars is intricate, requiring advanced technology and strict quality control to ensure the final product meets industry standards. A cold rolled steel bar factory operates through a series of well-defined steps to transform raw materials into high-quality steel products suitable for diverse applications.

The Process of Cold Rolling

Cold rolling is a method that involves passing steel through rollers at room temperature to achieve the desired thickness and mechanical properties. Unlike hot rolling, which occurs at elevated temperatures, cold rolling helps improve the strength and surface finish of the steel. The process begins with steel billets or slabs that are first heated and then subjected to several passes through a series of rollers.

The cold rolled steel bars produced have superior dimensional accuracy, enhanced mechanical properties, and a smooth surface finish. These characteristics make cold rolled steel bars preferable for applications that require high strength-to-weight ratios and excellent corrosion resistance.

Key Equipment in the Factory

A cold rolled steel bar factory is equipped with various machines and technologies that facilitate efficient production

. Key pieces of equipment include1. Reheating Furnaces These are used to heat billets to the necessary temperature before they enter the rolling mills. Proper heating ensures that the material is malleable and can be effectively shaped without cracking.

2. Rolling Mills These mills are the heart of the factory, comprising several stands of rollers that progressively reduce the thickness of the steel bars. Advanced control systems monitor the pressure and temperature during the rolling process to maintain consistency.

3. Cutting and Shearing Machines Once the desired length and diameter of the steel bars are achieved, cutting machines are employed to shear the products to the required specifications.

cold rolled steel bar factory

4. Surface Finishing Equipment To enhance the surface quality of the steel bars, factories often use cleaning systems and finishing machines that remove mill scale and any impurities, ensuring a clean surface ready for subsequent treatments.

5. Quality Control Stations Integrated quality control areas equipped with measuring and testing tools are crucial for maintaining high standards. They conduct checks such as tensile testing, hardness testing, and dimensional measurements to ensure the bars meet the necessary specifications.

Environmental Considerations

Modern cold rolled steel bar factories are increasingly focusing on sustainable practices. The steel industry is known for its significant energy consumption and environmental impact. Manufacturers are finding ways to reduce waste, recycle materials, and lower energy consumption during production. Implementing advanced technologies such as electric arc furnaces, which have a lower carbon footprint compared to traditional methods, is a step towards greener production practices.

Market Trends and Demands

The demand for cold rolled steel bars is influenced by various factors, including economic growth, infrastructure projects, and advancements in technology. The construction sector, for instance, requires high-quality steel bars for reinforcement in concrete structures. Meanwhile, the automotive industry constantly seeks lighter and stronger materials to enhance vehicle performance and fuel efficiency.

As industries evolve, the specifications for cold rolled steel also change, requiring factories to adapt their production methods and invest in research and development. Innovations such as alloying techniques and surface treatments are being explored to create products that cater to specific market needs.

Conclusion

In conclusion, a cold rolled steel bar factory plays a vital role in the manufacturing landscape, providing essential materials for various sectors. With advancements in technology, quality control measures, and a commitment to sustainability, these factories are well-positioned to meet the ever-evolving demands of the industrial world. As the market continues to grow, the importance of innovation and efficiency in cold rolled steel production will only increase, ensuring that manufacturers remain competitive and capable of producing high-quality steel products.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

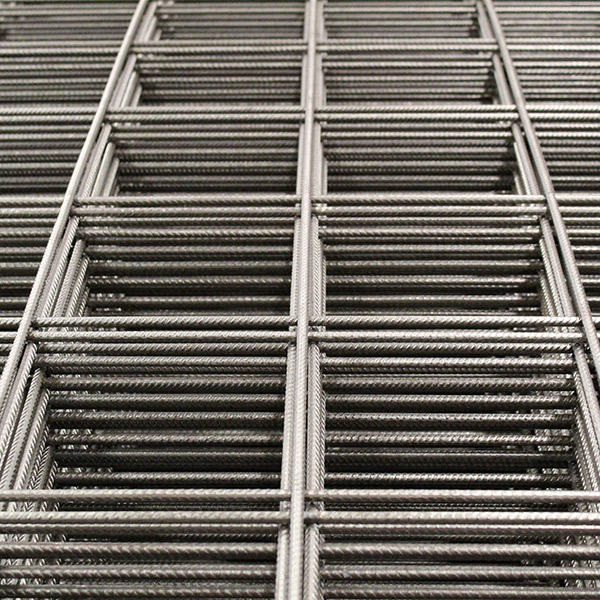

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025