Nov . 20, 2024 19:51 Back to list

cold rolled steel bar

The Importance of Cold-Rolled Steel Bars in Modern Manufacturing

Cold-rolled steel bars are a vital component in the vast landscape of modern manufacturing and construction. Known for their exceptional strength and precise dimensions, these bars derive their properties from a unique manufacturing process that enhances both mechanical characteristics and surface quality. As industries continue to evolve, the role of cold-rolled steel bars in various applications cannot be overstated.

Understanding Cold-Rolled Steel

Cold rolling is a process that involves passing steel through rollers at room temperature to achieve a desired thickness and improve surface finish. Unlike hot rolling, where steel is processed at elevated temperatures, cold rolling results in better dimensional accuracy and surface smoothness. This process not only refines the material's properties but also increases its yield strength and hardness through strain hardening.

The production of cold-rolled steel bars typically begins with hot-rolled steel. Once the hot-rolled bars are cooled to room temperature, they undergo further processing in cold rolling mills. This includes multiple passes through rollers, which gradually reduce the cross-section of the steel. The bars are then cut to length and can be subjected to additional treatments, such as annealing, to enhance their ductility and toughness.

Advantages of Cold-Rolled Steel Bars

Cold-rolled steel bars offer several advantages over their hot-rolled counterparts. One of the primary benefits is their superior dimensional accuracy. The cold rolling process allows for precise control over thickness, width, and length, making these bars ideal for applications where tight tolerances are critical. This precision reduces the need for additional machining processes, which can save both time and money.

Another significant advantage of cold-rolled steel bars is their enhanced surface quality. The cold rolling process results in a smooth finish that often requires no further treatment. This surface quality is crucial in industries where corrosion resistance and aesthetic appeal are important, such as automotive and architectural applications. Furthermore, the cold-rolled bars exhibit better fatigue resistance and overall performance, making them suitable for demanding environments.

cold rolled steel bar

Applications of Cold-Rolled Steel Bars

The versatile nature of cold-rolled steel bars allows them to be used in a wide range of applications across various sectors. In the automotive industry, these bars are often used in the production of components such as axles, gears, and structural frames. Their high strength-to-weight ratio contributes to the overall performance and efficiency of vehicles.

In the construction sector, cold-rolled steel bars are essential for reinforcing concrete structures. They are commonly utilized in the manufacture of rebar, which enhances the tensile strength of concrete, ensuring the stability and durability of buildings and infrastructures. Additionally, these bars are also used in the production of mechanical parts, fasteners, and other industrial components that require exceptional strength and precision.

Moreover, cold-rolled steel bars find applications in the manufacturing of furniture and appliances, where aesthetic appeal and structural integrity are paramount. The smooth surface and the ability to produce custom dimensions make these bars a popular choice for designers and engineers alike.

Conclusion

In summary, cold-rolled steel bars play a crucial role in the manufacturing and construction industries, offering a unique combination of strength, precision, and surface quality. The advantages that cold rolling provides—such as dimensional accuracy, enhanced surface finish, and superior mechanical properties—make these bars indispensable for a variety of applications. As technology continues to progress, the demand for cold-rolled steel bars will likely continue to rise, driving innovation and improvements in manufacturing processes.

Investing in cold-rolled steel bars not only fosters better product quality but also promotes sustainability through reduced waste and efficient manufacturing practices. As we look to the future, the importance of these materials in building a resilient and advanced industrial landscape is clear, making them a cornerstone of modern production techniques.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

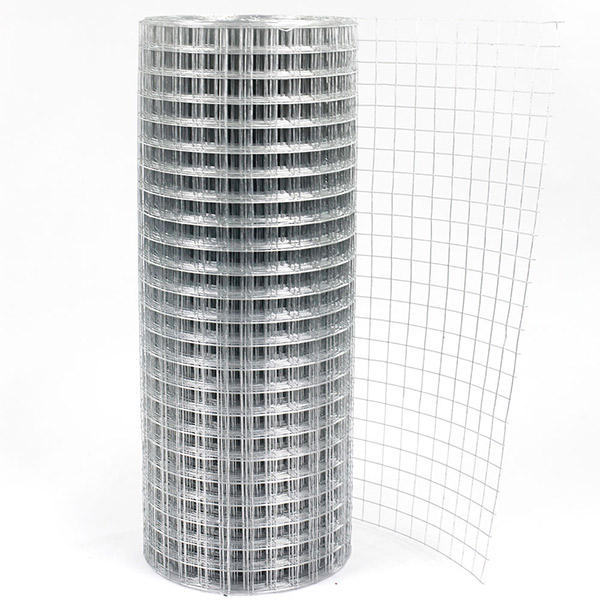

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025