Nov . 06, 2024 03:31 Back to list

cold rolled rebar manufacturer

The Role of Cold Rolled Rebar Manufacturers in Modern Construction

In the ever-evolving landscape of construction, the demand for high-quality materials has never been greater. Among these materials, cold rolled rebar has emerged as a preferred choice for many engineers and builders. Cold rolled rebar, characterized by its enhanced strength and durability, plays a crucial role in reinforcing concrete structures. This article aims to explore the significance of cold rolled rebar manufacturers in meeting the needs of the construction industry.

Cold rolled rebar is produced through a specific manufacturing process that involves the cold working of steel. Unlike hot rolled rebar, which undergoes significant heating during production, cold rolled rebar is crafted at room temperature. This process optimizes the mechanical properties of the steel, resulting in a product that boasts superior tensile strength while maintaining a lightweight profile. Such qualities make cold rolled rebar an integral component in various construction applications, from residential buildings to large-scale infrastructure projects.

Manufacturers of cold rolled rebar are tasked with ensuring that their products meet stringent quality standards. This involves rigorous testing and adherence to international specifications, such as ASTM A615 or A706. Quality assurance is vital, as the structural integrity of buildings largely depends on the materials used. Cold rolled rebar manufacturers invest in advanced technology and equipment to ensure a consistent and reliable output, providing builders with confidence in their choices.

cold rolled rebar manufacturer

Moreover, sustainability has become a focal point within the construction materials industry. Many cold rolled rebar manufacturers are adopting eco-friendly practices in their production processes. This includes utilizing recycled steel and reducing waste, showcasing a commitment to environmentally responsible manufacturing. By prioritizing sustainability, these manufacturers not only meet regulatory requirements but also cater to the growing demand for green construction materials.

The collaboration between cold rolled rebar manufacturers and construction companies is essential for success. Customization options offered by manufacturers, such as varying diameters and lengths, enable builders to tailor their projects accordingly. Additionally, manufacturers often provide technical support, assisting engineers in selecting the appropriate type of rebar for specific applications.

In conclusion, cold rolled rebar manufacturers play a pivotal role in the construction industry by providing high-quality materials that enhance the durability and strength of structures. Their commitment to quality, sustainability, and customer collaboration positions them as indispensable partners for builders striving for excellence. As construction techniques advance and demands evolve, the importance of reliable cold rolled rebar manufacturers will only continue to grow.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

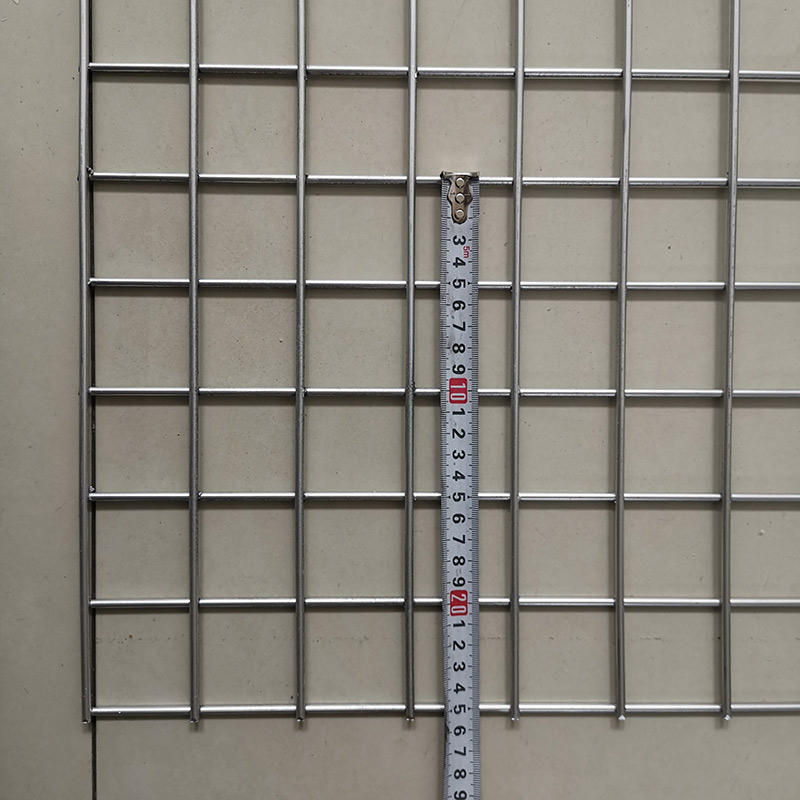

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025