Dec . 11, 2024 10:04 Back to list

Understanding the Benefits and Applications of Cold Rolled Rebar in Construction

Understanding Cold Rolled Rebar Benefits, Applications, and Processes

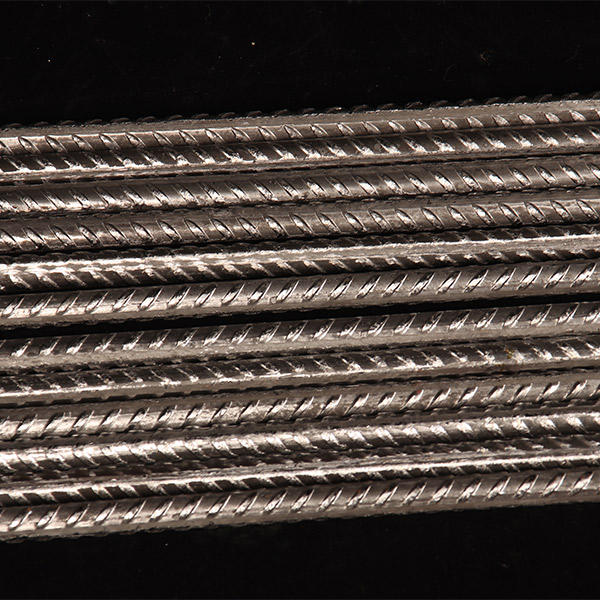

Cold rolled rebar, a type of steel reinforcement, has gained considerable attention in the construction industry for its superior properties compared to traditional hot rolled rebar. While most people are accustomed to the hot rolled variety, cold rolled rebar offers unique characteristics that make it an essential material for various applications. In this article, we will explore the process of cold rolling, the benefits it offers, and its applications in construction.

The Cold Rolling Process

Cold rolling is a metalworking process that involves the deformation of metals at room temperature, which results in a refined microstructure and enhanced properties. For rebar manufacturing, the process begins with hot rolled steel which undergoes a series of cool rolling passes. This technique not only alters the shape and size of the rebar but also enhances its mechanical properties.

During the cold rolling process, rebar is subjected to repeatedly being passed through rollers, which apply significant pressure, compressing and elongating the material. This leads to a higher yield strength, improved tensile strength, and better ductility compared to hot rolled rebar. The method typically results in a more uniform size and surface finish, ensuring better bonding with concrete, which is crucial for the structural integrity of buildings and infrastructure.

Benefits of Cold Rolled Rebar

1. Higher Strength One of the most significant advantages of cold rolled rebar is its increased strength. The cold working process induces strain hardening, allowing the material to withstand greater loads and stresses without yielding.

2. Better Bonding The smooth and uniform surface finish of cold rolled rebar enhances its adhesion to concrete. This results in a stronger composite material, as the key to effective structural performance is ensuring that the rebar and concrete work together.

3. Versatility Cold rolled rebar can be manufactured in various grades and sizes, making it suitable for a wide range of structural applications. Whether used in residential buildings, bridges, or commercial complexes, the material can cater to diverse engineering needs.

4. Corrosion Resistance Cold rolled rebar often comes with a protective coating, such as epoxy or galvanized finishes, which further enhances its corrosion resistance. This is particularly beneficial in environments where rebar is exposed to moisture and chemicals, increasing the longevity of structures.

cold rolled rebar

5. Cost-Effectiveness Although the initial cost of cold rolled rebar may be slightly higher than that of hot rolled variants, its long-term benefits, such as improved durability and reduced maintenance costs, make it a cost-effective choice for construction projects.

Applications of Cold Rolled Rebar

Cold rolled rebar is extensively used in various construction scenarios. Its benefits make it ideal for applications where structural integrity is paramount. Some of the common uses include

1. High-Rise Buildings Due to its superior strength and bonding characteristics, cold rolled rebar is often used in the foundations and frameworks of skyscrapers where load-bearing capacity is critical.

2. Bridges and Highways The durability and resistance to environmental factors make cold rolled rebar a preferred choice for bridges and road infrastructure, ensuring safety and longevity.

3. Industrial Structures Many industrial facilities utilize cold rolled rebar to support heavy machinery and equipment, where robust reinforcement is essential.

4. Seismic Zones In areas prone to earthquakes, the enhanced ductility of cold rolled rebar provides the flexibility needed to withstand seismic forces, making it a safer alternative in these regions.

5. Water Retaining Structures Its corrosion resistance makes cold rolled rebar suitable for water tanks, treatment facilities, and reservoirs where exposure to water is a factor.

Conclusion

Cold rolled rebar represents a significant advancement in reinforcement materials, offering several benefits over traditional hot rolled options. With higher strength, enhanced bonding properties, and superior corrosion resistance, it stands out as an essential material in modern construction. As the industry continues to evolve, the demand for innovative materials like cold rolled rebar will only increase, driving further research and development to improve construction practices worldwide. Whether in high-rise buildings or critical infrastructure, understanding and utilizing cold rolled rebar can significantly impact the quality and longevity of construction projects.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025