Oct . 11, 2024 20:17 Back to list

cold rolled channel steel bar black iron factories

Understanding Cold Rolled Channel Steel Bar and Black Iron Factories

In the world of construction and manufacturing, the materials used play an essential role in determining the quality and durability of the finished products. Among these materials, cold rolled channel steel bars and black iron have gained significant traction in various industries. This article delves into the characteristics of these materials, the manufacturing processes involved, and the significance of factories specializing in these products.

Cold rolled channel steel bars are known for their unique properties, making them ideal for a range of structural applications. The process of cold rolling involves pressing steel at room temperature through rolls to create shapes like channels, angles, and plates. This process results in a tighter tolerance, improved surface finish, and enhanced mechanical properties compared to hot rolled products. Cold rolled channel bars are commonly used in construction, automotive, and machinery industries due to their strength, durability, and versatility. They are particularly favored in applications where precision is critical.

On the other hand, black iron refers to a type of steel that is not coated with any protective materials. It retains an untreated finish, which allows for easy welding and machining. Black iron is often used in plumbing and gas lines due to its ability to withstand high pressure and temperature. The aesthetic appeal of black iron also makes it a popular choice in construction and architectural projects where a raw, industrial look is desired.

cold rolled channel steel bar black iron factories

The factories that produce cold rolled channel steel bars and black iron play a crucial role in the supply chain for these materials

. These facilities employ advanced manufacturing techniques and quality control measures to ensure that the products meet industry standards. The production begins with the selection of high-grade raw materials, which are then subjected to rigorous testing to ensure their suitability for further processing.Once the raw materials are approved, the cold rolling process is initiated. Advanced machinery is employed to shape and fine-tune the steel into the desired channel profiles. Quality checks are carried out at various stages to detect any inconsistencies or defects in the products. After the rolling is complete, the steel bars may undergo additional processes such as annealing or surface treatments to enhance their properties further.

Sustainability is becoming a significant focus for many steel manufacturers, including those specializing in cold rolled channel steel and black iron. Factories are increasingly adopting eco-friendly practices, such as recycling scrap metal and reducing energy consumption during production. This shift towards sustainability not only benefits the environment but also helps manufacturers meet the rising demand for green construction materials.

In conclusion, cold rolled channel steel bars and black iron are pivotal materials in modern manufacturing and construction. The factories dedicated to producing these products must embrace innovation, quality control, and sustainability to remain competitive in an evolving market. As industries continue to grow, the demand for high-quality steel products will undeniably remain strong, ensuring that these factories play an essential role in shaping the future of construction and manufacturing.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

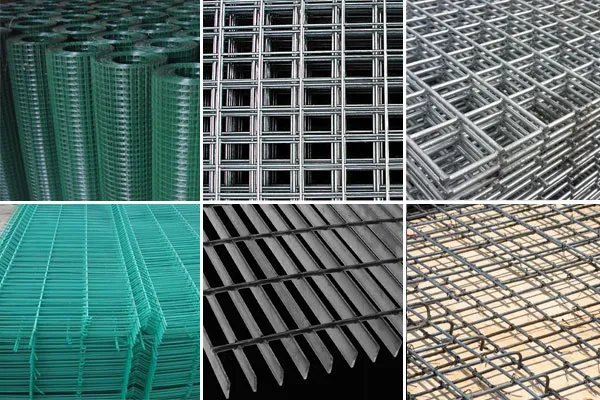

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025