Nov . 08, 2024 11:19 Back to list

Cold Rolled Channels and Black Iron Steel Bars for Structural Applications

Understanding Cold Rolled Channel Steel Bar and Black Iron

Cold rolled channel steel bars and black iron products are essential materials widely used in various construction and manufacturing industries. As infrastructure continues to evolve, understanding the characteristics, production processes, and applications of these materials is crucial for engineers, manufacturers, and builders.

What is Cold Rolled Channel Steel?

Cold rolled channel steel refers to steel that has undergone a cold rolling process to create a U-shaped channel with precise dimensions and a smooth finish. This process involves reducing the material thickness at room temperature, which enhances its mechanical properties and provides a finer surface finish compared to hot-rolled steel. Cold rolling improves characteristics such as strength, hardness, and surface quality, making it an ideal choice for applications requiring high precision and finish.

Cold rolled channel steel bars are commonly used in construction frameworks, support structures, and various architectural elements due to their high strength-to-weight ratio. Their shape allows for effective load distribution, making them suitable for beams, columns, and other structural components. In addition, the ability to create custom sizes and shapes enables manufacturers to cater to specific project requirements.

The Role of Black Iron

Black iron is a term used to describe uncoated, mild steel that has not undergone any corrosion protection processes. It typically has a matte black finish due to the oxidation of steel during manufacturing. Black iron is known for its malleability, machinability, and relatively low cost, making it a popular choice for various applications, including piping, construction, and automotive components.

While black iron is not as strong as cold rolled channel steel, it plays a vital role in applications that do not require high tensile strength but still demand durability and reliability. For instance, black iron tubing is often used in structural applications where weight is a concern, providing sufficient strength without unnecessary bulk. Moreover, black iron can easily be welded and shaped, making it a versatile material for custom projects.

Production Process

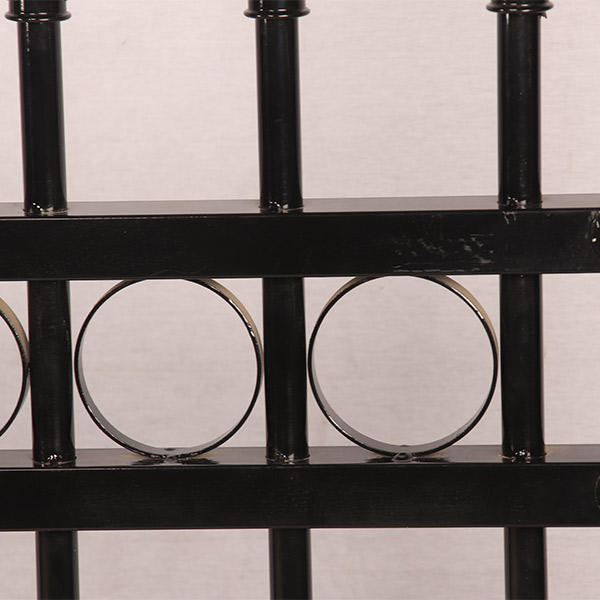

cold rolled channel steel bar black iron

The production of cold rolled channel steel involves several stages. Initially, hot-rolled steel strips are produced by heating steel billets and rolling them into flat sheets. These sheets are then subjected to a process of cold rolling, where they are further reduced in thickness at room temperature. This stage enhances the metal's strength through work hardening while maintaining precise dimensions and smooth finishes.

Following the cold rolling process, the strips are cut to the desired lengths and formed into channel shapes using specialized bending equipment. Quality control is critical throughout the production process to ensure that the final product meets industry standards for strength, dimensions, and surface finish.

In contrast, the production of black iron involves similar initial steps but does not undergo the cold rolling process. Instead, the steel is hot-rolled and left uncoated, preserving its natural state. This simplicity in production contributes to its cost-effectiveness as compared to cold rolled products.

Applications in Industry

Cold rolled channel steel bars and black iron serve a multitude of purposes across various sectors. The construction industry heavily relies on cold rolled channel steel for constructing frames, support beams, and trusses due to its strength and stability. In mechanical applications, it is used in manufacturing scaffolding, brackets, and supports where precision and durability are critical.

On the other hand, black iron finds its applications primarily in plumbing, heating, and electrical systems. Its resistance to high pressure and heat makes it suitable for piping systems, while its malleability allows for easy shaping in various fixtures and fittings.

Conclusion

In summary, cold rolled channel steel bars and black iron are crucial components in modern construction and manufacturing. Their unique properties cater to different needs, from the precision and strength of cold rolled products to the versatility of black iron. As industries continue to advance, understanding these materials' characteristics, production processes, and applications will ensure better material selection and enhance overall project outcomes.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025