Oct . 21, 2024 17:12 Back to list

Manufacturers of Cold Ribbed Steel Bars for Reinforcing Mesh Production

The Rise of Cold Ribbed Steel Bars in Reinforcing Mesh Manufacturing

In modern construction and civil engineering, the importance of high-quality reinforcement materials cannot be overstated. Among these materials, cold ribbed steel bars have emerged as a popular choice for reinforcing meshes due to their numerous advantages and versatility. This article will delve into the characteristics and benefits of cold ribbed steel bars, exploring their manufacturing processes and the role they play in construction.

Understanding Cold Ribbed Steel Bars

Cold ribbed steel bars, also known as cold worked steel bars, are produced through a process that involves rolling steel at a temperature below its recrystallization point. This method not only enhances the strength and durability of the bars, but also allows for the creation of surface deformations, or ribs, which significantly improve bond strength when used in concrete applications.

These bars come in various diameters and lengths, making them suitable for a wide range of applications. The ribbed surface offers mechanical interlocking with concrete, leading to enhanced load-bearing capacity and resistance to pull-out forces. This is particularly beneficial in structures that require high tensile strength and stability, such as bridges, high-rise buildings, and industrial facilities.

The Manufacturing Process

The production of cold ribbed steel bars involves several key stages. First, quality raw steel is selected, often sourced from reputable steel mills. The steel is then heated and processed through a series of rolling mills, where it is shaped into bars of desired dimensions. As the bars are rolled, they are cooled gradually to maintain their structural integrity.

Once the rolling process is complete, the bars undergo a cold working process. This involves additional mechanical deformation, enhancing their yield strength and tensile strength. The final stage includes surface treatment to remove any impurities and improve corrosion resistance, a vital factor in ensuring the longevity of the bars in various environments.

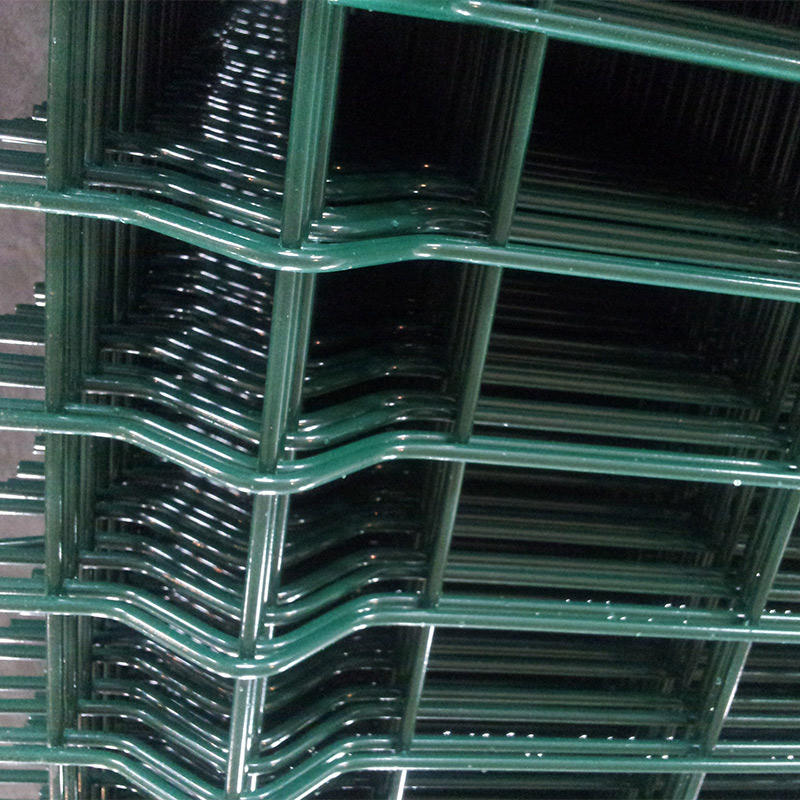

cold ribbed steel bar for reinforcing mesh manufacturers

Applications in Reinforcing Mesh

One of the primary applications of cold ribbed steel bars is in the production of reinforcing meshes. These meshes are critical for providing structural support in various construction projects. They are widely used in slab construction, walls, and foundations, where they help distribute loads evenly and prevent cracking.

Reinforcing meshes created from cold ribbed steel bars offer several advantages over traditional reinforcement methods. The interconnected structure of the mesh allows for uniform load distribution, reducing the likelihood of weak points that can lead to structural failure. Moreover, the ribbed texture of the bars improves the bond with concrete, ensuring that the reinforcement remains firmly integrated within the structure.

Advantages Over Other Reinforcement Materials

Cold ribbed steel bars present several benefits compared to other types of reinforcement materials. One significant advantage is their superior strength-to-weight ratio. They provide high strength while remaining relatively lightweight, making them easier to handle and install. This can lead to reduced labor costs and accelerated construction timelines.

Additionally, cold ribbed steel bars exhibit excellent resistance to fatigue and deformation, making them suitable for dynamic loading conditions often encountered in structures such as bridges and industrial buildings. Their corrosion resistance, particularly when surface-treated, minimizes the risk of degradation over time, thereby extending the lifespan of the reinforcing mesh.

Conclusion

The adoption of cold ribbed steel bars in reinforcing mesh manufacturing reflects a broader trend towards the use of high-performance materials in construction. Their strength, durability, and adaptability make them an ideal choice for various applications, from residential buildings to large-scale infrastructure projects. As the construction industry continues to evolve, the demand for innovative reinforcement solutions like cold ribbed steel bars will likely increase, placing them at the forefront of modern construction practices. Embracing these advanced materials is essential for engineers and builders seeking to ensure the safety, longevity, and efficiency of their projects.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025