Nov . 20, 2024 14:39 Back to list

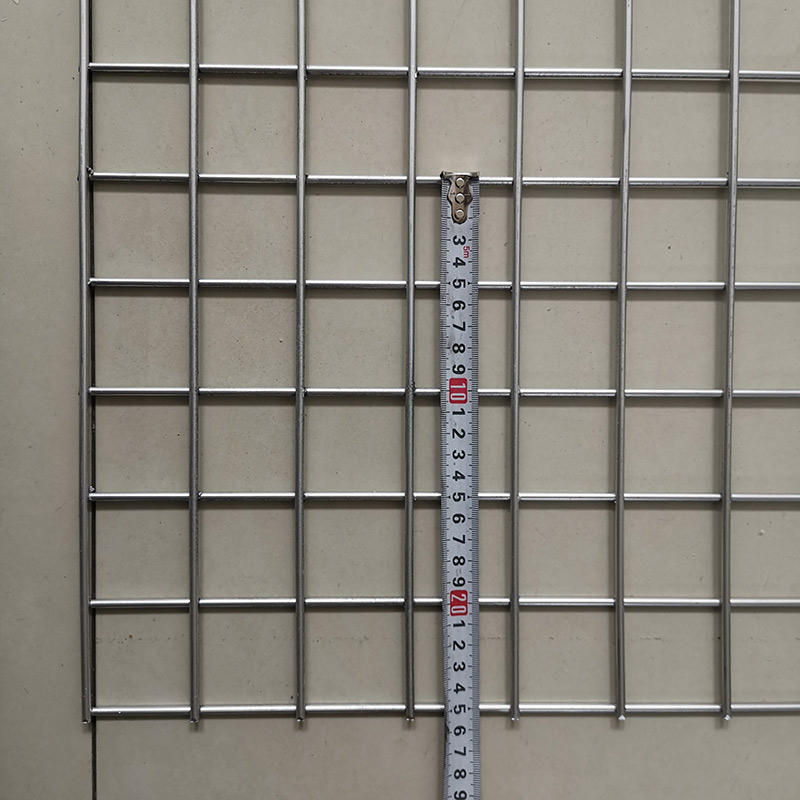

cold ribbed steel bar for reinforcing mesh factory

The Importance of Cold Ribbed Steel Bars for Reinforcing Mesh

In the construction industry, the integrity and strength of structures are paramount. One of the significant components that contribute to this strength is reinforcement mesh, which is essential for enhancing the performance of concrete. Cold ribbed steel bars have emerged as a popular choice for manufacturing reinforcing mesh due to their unique properties and advantages. This article explores the characteristics, benefits, and applications of cold ribbed steel bars in the production of reinforcing mesh.

What are Cold Ribbed Steel Bars?

Cold ribbed steel bars are steel rods that undergo a specific manufacturing process where they are cold-worked to improve strength and flexibility. These bars are characterized by transverse ribs that create an increased bond between the steel and concrete, enhancing the structural integrity of the finished product. The ribs provide mechanical interlocking that helps prevent slippage, making them ideal for reinforcement purposes.

Benefits of Cold Ribbed Steel Bars

1. Enhanced Bonding The ribbed surface of cold ribbed steel bars plays a crucial role in ensuring better bonding with concrete. This superior adhesion allows for improved load-bearing capacity and reduces the risk of structural failure.

2. High Strength The cold manufacturing process increases the tensile strength of the steel, making these bars capable of withstanding higher loads without yielding or breaking. This quality is essential in load-bearing applications, where safety and reliability are critical.

3. Corrosion Resistance Many cold ribbed steel bars are treated or coated to enhance their corrosion resistance, which is crucial for longevity in harsh environmental conditions. This feature helps reduce maintenance costs and prolongs the lifespan of the structures they reinforce.

4. Versatility Cold ribbed steel bars can be produced in various diameters and lengths, making them suitable for a wide range of applications. They can be easily bent or cut to fit specific project requirements, giving builders and engineers flexibility in their designs.

cold ribbed steel bar for reinforcing mesh factory

5. Cost-Effectiveness While the initial cost of cold ribbed steel bars may be higher than traditional bars, their durability and strength often result in overall cost savings due to lower repair and maintenance expenses over time.

Applications of Cold Ribbed Steel Bars in Reinforcing Mesh

Cold ribbed steel bars are commonly used in the production of reinforcing mesh for various construction applications, including

- Building Foundations In residential and commercial structures, reinforcing mesh made from cold ribbed steel bars is laid within concrete foundations to provide extra support, ensuring stability and preventing cracking under pressure.

- Roads and Bridges The durability and strength of cold ribbed steel bars make them ideal for infrastructure projects. Reinforcing mesh is commonly used in highways and bridges to support heavy traffic loads and withstand environmental stressors.

- High-Rise Buildings As urbanization continues to rise, there is a growing demand for high-rise buildings. Cold ribbed steel bars are integral in reinforcing the concrete cores and slabs of these structures, contributing to their safety and stability.

- Industrial Applications Factories and warehouses often require robust flooring systems. Reinforcing mesh made from cold ribbed steel bars provides the necessary support for heavy machinery and equipment, ensuring the safety of both the structure and its occupants.

Conclusion

Cold ribbed steel bars have revolutionized the construction industry by offering superior reinforcement solutions through reinforcing mesh. Their enhanced bonding capabilities, high strength, corrosion resistance, versatility, and cost-effectiveness make them an exceptional choice for various applications. As construction techniques continue to advance, the role of cold ribbed steel bars will remain vital in ensuring the safety, durability, and longevity of structures across the globe. Whether in residential buildings, highways, or industrial facilities, their importance cannot be overstated, making them a fundamental component in modern construction practices.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025