Oct . 18, 2024 12:45 Back to list

High-Quality Cold Drawn Flat Steel Supplier for Various Applications

Cold Drawn Flat Steel Manufacturers An Overview

Cold drawn flat steel is a vital component in various industries, known for its precision and high-quality characteristics. It is produced by various manufacturers across the globe, offering a range of specifications that cater to different applications. This article will explore what cold drawn flat steel is, how it is manufactured, and the key players in the industry.

What is Cold Drawn Flat Steel?

Cold drawn flat steel refers to steel products that are processed through a method of drawing steel at room temperature. This process enhances the material's properties, resulting in improved mechanical characteristics such as strength, surface finish, and dimensional accuracy. The most commonly produced forms of cold drawn flat steel are strips, plates, and bars, which are used extensively in automotive, construction, machinery, and consumer goods sectors.

The cold drawing process involves several steps, including heating the steel, drawing it through a die, and then cooling it. This method not only refines the steel's structure but also reduces its cross-section, allowing for the production of uniform thickness and dimensions. As a result, cold drawn flat steel products exhibit high tensile strength and excellent surface quality.

The Manufacturing Process

The manufacturing of cold drawn flat steel encompasses several stages

1. Material Selection Manufacturers typically start with hot-rolled steel as the raw material. This steel is chosen for its intrinsic properties, which can be enhanced during the cold drawing process.

2. Cleaning and Preparation The hot-rolled steel is cleaned to remove any scale, oil, or dirt that could affect the final product's quality. This may involve chemical treatments or mechanical processes.

3. Cold Drawing The cleaned steel is then drawn through a series of dies to reduce its thickness and improve its mechanical properties. This step requires careful control of the drawing speed, temperature, and friction to avoid defects.

4. Annealing To relieve the stresses induced during the drawing process, the cold drawn steel may undergo an annealing process. This step enhances ductility, making the material easier to work with in subsequent applications.

cold drawn flat steel manufacturer

Key Players in the Industry

The cold drawn flat steel market is populated by a diverse range of manufacturers, each offering unique products and services. Many key players focus on quality assurance, technological advancements, and customer satisfaction.

1. Large Corporations Major steel manufacturers like ArcelorMittal, U.S. Steel, and Nucor have established themselves as leaders in the cold drawn flat steel market. These companies invest heavily in technology and innovation, ensuring that they produce high-quality products that meet industry standards.

2. Specialized Manufacturers There are also smaller, specialized manufacturers that cater to niche markets or specific applications. These companies often provide customized solutions to meet the unique needs of their clients, offering tailor-made thickness, width, and finish options.

3. Local and Regional Players Many local manufacturers excel in providing cold drawn flat steel products to regional markets. They may focus on specific industries, such as automotive or construction, and develop strong relationships with local clients.

Applications of Cold Drawn Flat Steel

Cold drawn flat steel is used in a wide range of applications due to its versatility. In the automotive industry, it is essential for producing components such as brackets, frames, and axles. In construction, it serves as a reliable material for structural components, reinforcing bars, and connectors. Additionally, its excellent surface finish makes it ideal for consumer goods, including appliances and furniture.

Conclusion

In conclusion, cold drawn flat steel manufacturers play a crucial role in various industries, providing high-quality steel products that enhance performance in numerous applications. The precise manufacturing process and the capabilities of key players ensure that the market remains competitive, continually evolving to meet the demands of modern manufacturing. As industries continue to innovate and grow, the importance of cold drawn flat steel and its manufacturers will only increase, solidifying their place in the global steel market. Whether for automotive parts or structural applications, cold drawn flat steel remains an indispensable resource in today’s economy.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

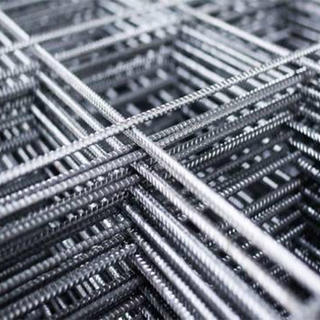

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025