Nov . 04, 2024 12:04 Back to list

Cold Drawn Flat Steel Specifications and Applications for Structural Use

Cold Drawn Flat Steel An Overview

Cold drawn flat steel is a type of steel product that has undergone a significant manufacturing process designed to improve its mechanical properties and enhance its dimensional accuracy. The cold drawing process involves pulling steel through a series of dies at room temperature, which alters the metal's structure and results in greater strength and precision. This article explores the characteristics, manufacturing process, applications, and advantages of cold drawn flat steel.

Characteristics of Cold Drawn Flat Steel

Cold drawn flat steel is known for its high precision and fine surface finish. The cold drawing process reduces the cross-sectional area of the steel, leading to a density that is more uniform compared to other steel products. This uniformity contributes to the improved mechanical properties of the steel, making it stronger and more resilient to deformation. Typically available in a variety of thicknesses and widths, cold drawn flat steel can be tailored to meet specific requirements, making it an ideal choice for numerous applications.

Another vital characteristic of cold drawn flat steel is its excellent tolerance levels. The manufacturing process allows for minimal variation in dimensions, ensuring that the end products fit seamlessly into assembly processes. This aspect is particularly important in industries where precision is critical, such as aerospace and automotive manufacturing.

Manufacturing Process

The cold drawing process begins with heated steel bars or coils, which are then cooled before being subjected to drawing. The steel is pulled through a series of tapered dies that progressively reduce the steel’s thickness while increasing its length. During this process, the steel is subjected to plastic deformation, which realigns the internal microstructure and increases dislocation density. The result is a product that boasts enhanced strength and ductility.

Once the desired dimensions are achieved, cold drawn flat steel may undergo additional processes, such as annealing or surface finishing, to further improve its properties and appearance. Annealing alleviates stresses that may have developed during drawing, allowing the steel to retain more ductility without sacrificing strength. Surface treatments can also be applied to enhance corrosion resistance or prepare the steel for subsequent coatings or paint applications.

Applications

The versatility of cold drawn flat steel makes it suitable for a wide range of applications across different industries. Some common uses include

1. Automotive Industry Cold drawn flat steel is widely employed in the manufacturing of components such as chassis parts, brackets, and structural reinforcements, where strength and precision are paramount.

cold drawn flat steel

3. Construction Structural components such as beams, channels, and frames often utilize cold drawn flat steel due to its ability to provide robust support with reduced weight.

4. Machinery and Equipment Cold drawn flat steel is frequently used in the production of precision tools and machinery parts that require exact dimensions and strength to operate effectively.

Advantages of Cold Drawn Flat Steel

The use of cold drawn flat steel offers several advantages

1. Improved Mechanical Properties The cold drawing process enhances the yield strength and tensile strength of the steel, making it superior to hot rolled forms.

2. Enhanced Tolerances and Finishes Products manufactured from cold drawn flat steel exhibit finer tolerances and smoother surface finishes, reducing the need for extensive machining.

3. Customizability Cold drawn flat steel can be produced to meet specific thickness, width, and length requirements, providing flexibility in design and application.

4. Cost-Effective Solutions While the initial processing may require more energy, the efficiency gained in the use of cold drawn flat steel often translates into long-term cost savings due to reduced wear on machinery and lower failure rates in final products.

Conclusion

Cold drawn flat steel is a vital material in modern manufacturing, offering a combination of strength, precision, and versatility that is essential in numerous industries. As technology advances and the demand for high-quality materials increases, cold drawn flat steel will continue to play a significant role in product development and innovation. Understanding its properties, processes, and applications can help industries make informed choices when selecting materials for their projects.

-

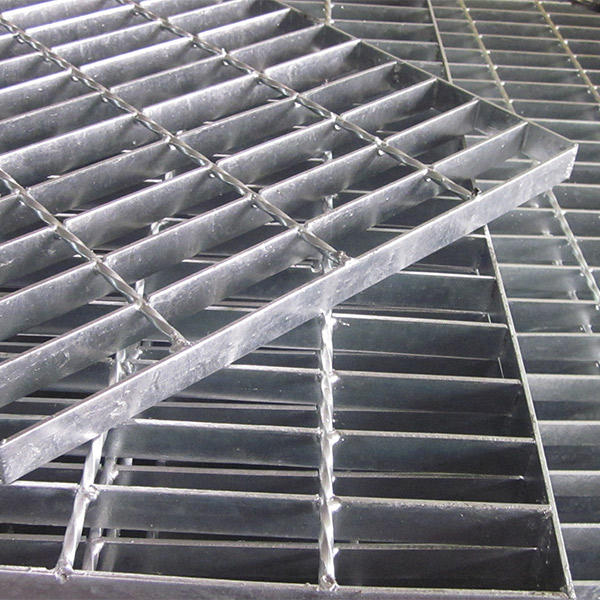

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025