Dec . 12, 2024 02:48 Back to list

chinese manufacturers concrete reinforcing mesh

The Role of Chinese Manufacturers in the Production of Concrete Reinforcing Mesh

Concrete reinforcing mesh plays a crucial role in the construction industry, providing strength and stability to structures ranging from residential buildings to large infrastructure projects. China, as a global manufacturing leader, plays an integral role in producing this essential construction material. This article explores the significance of Chinese manufacturers in the concrete reinforcing mesh market, their technological advancements, and their impact on global construction practices.

Understanding Concrete Reinforcing Mesh

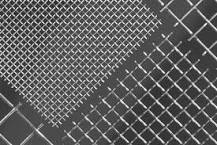

Concrete reinforcing mesh, commonly made of steel, consists of a grid of wires that are welded together to form a durable lattice structure. It is designed to enhance the tensile strength of concrete, preventing cracks and ensuring longevity in various applications such as floors, roads, and bridges. By distributing loads evenly across a concrete surface, reinforcing mesh helps withstand environmental stresses, making it a vital component in ensuring the durability and structural integrity of concrete constructions.

Chinese Manufacturing Landscape

China has emerged as a leading player in the manufacturing of concrete reinforcing mesh. With a robust industrial base and access to abundant raw materials, Chinese manufacturers can produce mesh at competitive prices while maintaining quality standards. The country's vast network of suppliers and manufacturers contributes to economies of scale, allowing for efficient production processes that meet both domestic and international demand. Furthermore, China’s strategic location and established trade routes facilitate the export of concrete reinforcing mesh to various regions, including North America, Europe, and Southeast Asia.

Advancements in Technology

Chinese manufacturers have made significant strides in technology, enhancing the production of concrete reinforcing mesh. The adoption of advanced machinery and automation in the manufacturing process has led to increased efficiency and precision. State-of-the-art welding techniques ensure that the joints within the mesh are robust and reliable, resulting in a product that meets stringent quality standards.

Additionally, the development of high-strength steel and innovative coatings has improved the performance of reinforcing mesh. Manufacturers are focusing on corrosion-resistant materials, which further enhance the longevity of concrete structures, particularly in challenging environments. This commitment to innovation not only boosts the quality of the mesh produced but also aligns with global construction trends aimed at sustainability and resilience.

chinese manufacturers concrete reinforcing mesh

Environmental Considerations

As the global focus on sustainability grows, Chinese manufacturers are increasingly adopting eco-friendly practices in their production processes. Efforts to reduce energy consumption and minimize waste are becoming standard in the industry. Many manufacturers are exploring options for recycling scrap materials, which contributes to the reduction of the carbon footprint associated with concrete reinforcing mesh production.

Additionally, some producers are investing in green technologies and renewable energy sources to power their manufacturing operations. This transition not only benefits the environment but also aligns with global standards and consumer expectations for sustainable construction practices.

Global Impact

The influence of Chinese manufacturers extends far beyond domestic markets. By providing high-quality concrete reinforcing mesh at competitive prices, they are playing a pivotal role in the construction industry worldwide. Engineering firms and contractors globally rely on affordable materials to complete their projects efficiently, and the availability of Chinese-manufactured mesh helps to keep costs down.

Moreover, the export of concrete reinforcing mesh from China supports international partnerships and collaborations. Countries with burgeoning construction sectors benefit from these materials, as they often lack local production facilities or may face higher costs from alternative suppliers.

Conclusion

In summary, Chinese manufacturers of concrete reinforcing mesh are essential to the global construction landscape. Through their commitment to innovation, efficiency, and sustainability, these manufacturers not only provide high-quality materials but also contribute to the overall advancement of construction practices worldwide. As infrastructure demands continue to grow, the role of China in the production and supply of concrete reinforcing mesh will become increasingly vital, ensuring the durability and resilience of structures for generations to come.

-

Precision 8mm Cold Drawn Wire Suppliers High Strength & Quality

NewsJun.04,2025

-

2021 Best Price Wire Mesh Direct Manufacturer Deals

NewsJun.04,2025

-

Premium 16mm Steel Bar Suppliers Durable & High-Strength Steel

NewsJun.04,2025

-

Premium 16 Gauge Black Annealed Tie Wire - Durable & Rust-Resistant

NewsJun.04,2025

-

Premium Binding Iron Wire High Strength & Durable Solutions

NewsJun.03,2025

-

Durable Galvanized Metal Wire for Construction Anti-Corrosion

NewsJun.03,2025