Jan . 25, 2025 06:13 Back to list

Cold Drawn Wire

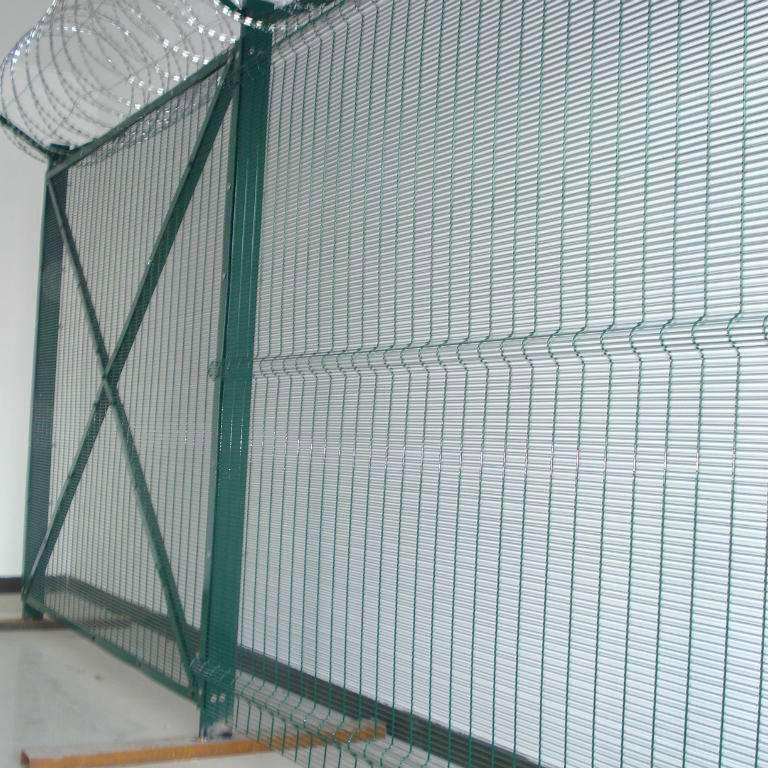

Enhancing construction projects with efficient materials is essential for modern infrastructure. One such crucial component is the China welded steel mesh panel, a product gaining attention for its remarkable performance in construction applications.

Authoritative manufacturers in China utilize state-of-the-art technology to produce these mesh panels, ensuring that they meet specific project needs. By collaborating closely with construction firms and project leads, manufacturers can customize panel dimensions, wire gauge, and mesh spacing, optimizing the product for each project's unique demands. This customization capability has positioned China as a leading supplier of high-quality welded steel mesh panels globally. Trust is a significant factor when selecting construction materials, and the welded steel mesh panels industry in China has consistently built a reputation for reliability. Many global construction companies have expressed satisfaction with the consistent quality and performance of these materials. Supplier credibility is enhanced through certifications and compliance with international construction standards, assuring clients of the product's legitimacy and reliability. In ensuring trustworthiness, manufacturers not only focus on product quality but also on environmental responsibility. Sustainable production practices are becoming a priority, with many manufacturers seeking ways to reduce carbon footprints and recycle waste materials during the manufacturing process. These environmentally friendly initiatives not only benefit the planet but also appeal to environmentally conscious construction companies seeking sustainable building practices. In conclusion, China welded steel mesh panels are more than just a construction material—they represent a commitment to quality, efficiency, and innovation in the construction industry. Whether you're an architect designing a cutting-edge structure or a builder seeking reliable reinforcement solutions, these panels offer an unbeatable combination of strength and flexibility. By understanding the unique benefits and applications of welded steel mesh panels, industry professionals can make informed decisions that enhance the success of their construction projects, ensuring safety, sustainability, and durability for years to come.

Authoritative manufacturers in China utilize state-of-the-art technology to produce these mesh panels, ensuring that they meet specific project needs. By collaborating closely with construction firms and project leads, manufacturers can customize panel dimensions, wire gauge, and mesh spacing, optimizing the product for each project's unique demands. This customization capability has positioned China as a leading supplier of high-quality welded steel mesh panels globally. Trust is a significant factor when selecting construction materials, and the welded steel mesh panels industry in China has consistently built a reputation for reliability. Many global construction companies have expressed satisfaction with the consistent quality and performance of these materials. Supplier credibility is enhanced through certifications and compliance with international construction standards, assuring clients of the product's legitimacy and reliability. In ensuring trustworthiness, manufacturers not only focus on product quality but also on environmental responsibility. Sustainable production practices are becoming a priority, with many manufacturers seeking ways to reduce carbon footprints and recycle waste materials during the manufacturing process. These environmentally friendly initiatives not only benefit the planet but also appeal to environmentally conscious construction companies seeking sustainable building practices. In conclusion, China welded steel mesh panels are more than just a construction material—they represent a commitment to quality, efficiency, and innovation in the construction industry. Whether you're an architect designing a cutting-edge structure or a builder seeking reliable reinforcement solutions, these panels offer an unbeatable combination of strength and flexibility. By understanding the unique benefits and applications of welded steel mesh panels, industry professionals can make informed decisions that enhance the success of their construction projects, ensuring safety, sustainability, and durability for years to come.

Latest news

-

Glass Food Storage Jar with Screw Wooden Lid - Anping County Puersen|Heat-Resistant & BPA Free

NewsAug.18,2025

-

Glass Food Storage Jar with Screw Wooden Lid - Anping County Puersen Hardware Wire Mesh Products Co., Ltd

NewsAug.18,2025

-

Glass Food Storage Jar with Screw Wooden Lid - Anping County Puersen Hardware Wire Mesh Products Co., Ltd|Eco-friendly Durable Storage

NewsAug.18,2025

-

Welded Wire Mesh for Industry | Factory Direct Supplies

NewsAug.18,2025

-

Glass Food Storage Jar with Screw Wooden Lid - Anping County Puersen Hardware Wire Mesh Products Co.,Ltd|Eco-Friendly, Heat-Resistant, Durable

NewsAug.17,2025

-

Glass Jar with Wooden Screw Lid-Anping County Puersen Hardware Wire Mesh Products Co.,Ltd|Thermal Resistance&Eco-Friendly

NewsAug.17,2025