Aug . 12, 2024 23:52 Back to list

China's Welded Mesh Solutions for Concrete Reinforcing Steel Applications and Structural Support

The Significance of Concrete Reinforcing Steel Welded Mesh in Construction

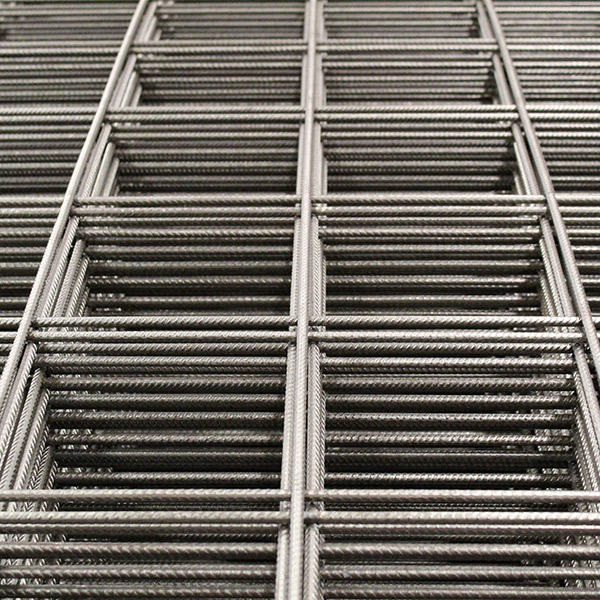

Concrete reinforcing steel welded mesh, often referred to simply as welded mesh, is an essential component in modern construction practices, particularly in areas where structural integrity is of paramount importance. This versatile material is made by welding together steel wires to form a mesh pattern, which is then embedded in concrete to enhance its tensile strength and durability.

The Manufacturing Process

The production of concrete reinforcing steel welded mesh typically involves drawing steel wires to the desired diameter, followed by a meticulous welding process. The wires are arranged in a grid-like pattern, and the intersections are welded together. This method not only ensures uniform strength across the mesh but also facilitates ease of handling and installation at construction sites. Various sizes and gauges of welded mesh can be produced, making it adaptable for different projects—from small residential buildings to massive infrastructure undertakings.

Benefits of Using Welded Mesh

One of the primary advantages of using concrete reinforcing steel welded mesh is its ability to distribute loads evenly across a concrete surface. Unlike traditional rebar, which requires significant labor for placement and tying, welded mesh simplifies the reinforcement process. This efficiency can lead to substantial time and cost savings during construction. Additionally, the uniformity of the mesh provides a consistent reinforcement solution, minimizing weak points and enhancing the overall structural performance of concrete elements.

Welded mesh also improves crack resistance in concrete slabs. Cracking is a common issue in concrete due to shrinkage and temperature changes. By integrating welded mesh, the tensile strength of the concrete is significantly increased, helping to prevent premature cracking and reducing the need for extensive repairs or reinforcements later in the project lifecycle.

Versatility in Applications

china concrete reinforcing steel welded mesh

Concrete reinforcing steel welded mesh is used in a wide array of applications. Its versatility makes it suitable for reinforcing floors, walls, slabs, and foundations in both residential and commercial buildings. Additionally, it plays a crucial role in the construction of pavements, bridges, and other civil engineering projects. The adaptability of welded mesh across various construction environments and its compatibility with different types of concrete make it an invaluable resource for engineers and architects alike.

Compliance and Standards

As with any construction material, compliance with industry standards is crucial. In China, welded mesh products are governed by specific national standards that ensure quality and safety. This includes regulations concerning the material properties of steel, the welding process, and product dimensions. Adhering to these standards not only guarantees the structural performance of the welded mesh but also instills confidence in stakeholders regarding the reliability of the construction.

Environmental Considerations

Another aspect worth noting is the environmental impact of using welded mesh. With increasing emphasis on sustainability in construction practices, the use of steel welded mesh contributes positively by minimizing waste. Its durability also extends the lifespan of concrete structures, reducing the need for frequent repairs or replacements. Moreover, steel is a highly recyclable material, making welded mesh an environmentally friendly choice that aligns with sustainable building practices.

Conclusion

In summary, concrete reinforcing steel welded mesh is a cornerstone of modern construction, providing superb structural support and performance. Its ease of use, efficiency in load distribution, and adaptability make it an ideal choice for diverse construction needs. As the construction industry continues to evolve, the importance of welded mesh is likely to grow, solidifying its role as an integral element for ensuring safe and robust structures. Emphasizing quality and adherence to standards will further enhance its reliability and sustainability in the years to come.

-

Glass Jar with Wooden Screw Lid-Anping County Puersen Hardware Wire Mesh Products Co.,Ltd|Thermal Resistance&Eco-Friendly

NewsAug.17,2025

-

Glass Food Storage Jar with Screw Wooden Lid - Anping County Puersen Hardware Wire Mesh Products Co., Ltd|High Borosilicate Glass&Eco-Friendly Design

NewsAug.17,2025

-

Glass Food Storage Jar with Screw Wooden Lid - Anping County Puersen Hardware Thermal Resistance Eco-Friendly Airtight Seal

NewsAug.17,2025

-

Glass Jar with Wooden Screw Lid - Anping County Puersen Hardware Wire Mesh Products Co., Ltd

NewsAug.17,2025

-

Diamond Steel Grating Factory: Leading Manufacturer & Supplier

NewsAug.17,2025

-

Glass Food Storage Jar with Screw Wooden Lid - Premium Eco-Friendly Storage Solution|Anping County Puersen Hardware Wire Mesh Products Co.,Ltd

NewsAug.16,2025