Feb . 07, 2025 02:55 Back to list

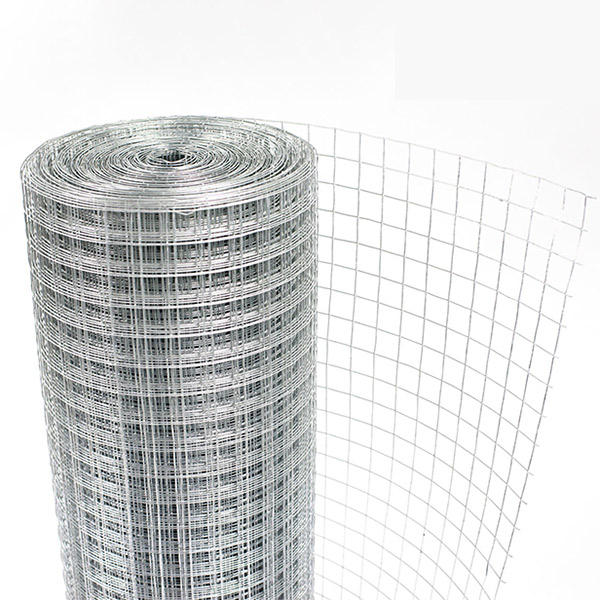

galvanized brick coil wire mesh masonry factories

China's hot-dipped galvanized iron wire has emerged as a cornerstone in the realm of heavy-duty materials, recognized globally for its immense utility, durability, and cost-effectiveness. Loved by construction experts and industrial professionals alike, it stands out amidst a wealth of alternatives because of its exceptional performance and reliability.

An often-underestimated aspect of China's expertise in producing galvanized iron wire is the symbiotic relationship between leading manufacturers and research institutions. Through collaborations, groundbreaking studies have consistently yielded improvements in the wire’s corrosion resistance and coating techniques. These innovations have ensured that every batch produced is a cut above previous iterations, providing consumers with a reliable, forward-thinking choice for their projects. For potential buyers across the globe, the importance of sourcing galvanized iron wire from reputable Chinese suppliers cannot be overstated. The credibility and trustworthiness of these suppliers are underscored by the rigorous standards met in both domestic and international markets. Certifications such as ISO9001 and CE standard are common among top-tier producers, providing assurance of adherence to global quality norms. Furthermore, detailed traceability reports often accompany shipments, offering clients transparency and peace of mind. Notably, China’s manufacturers have adopted eco-friendly galvanization techniques to reduce carbon footprints. This commitment to environmental sustainability meets modern ethical standards and aligns with global initiatives to promote sustainable industrial practices. Prospective buyers can take comfort in knowing that their choice supports a greener planet. Ultimately, hot-dipped galvanized iron wire from China embodies the pinnacle of expertise, capability, and trust in the field of construction and industrial materials. For industries contentious about quality and resilience, selecting this product assures a solution grounded in tested performance and reinforced by continuous innovation. It is not merely a purchase but an investment towards efficiency and longevity in varied applications.

An often-underestimated aspect of China's expertise in producing galvanized iron wire is the symbiotic relationship between leading manufacturers and research institutions. Through collaborations, groundbreaking studies have consistently yielded improvements in the wire’s corrosion resistance and coating techniques. These innovations have ensured that every batch produced is a cut above previous iterations, providing consumers with a reliable, forward-thinking choice for their projects. For potential buyers across the globe, the importance of sourcing galvanized iron wire from reputable Chinese suppliers cannot be overstated. The credibility and trustworthiness of these suppliers are underscored by the rigorous standards met in both domestic and international markets. Certifications such as ISO9001 and CE standard are common among top-tier producers, providing assurance of adherence to global quality norms. Furthermore, detailed traceability reports often accompany shipments, offering clients transparency and peace of mind. Notably, China’s manufacturers have adopted eco-friendly galvanization techniques to reduce carbon footprints. This commitment to environmental sustainability meets modern ethical standards and aligns with global initiatives to promote sustainable industrial practices. Prospective buyers can take comfort in knowing that their choice supports a greener planet. Ultimately, hot-dipped galvanized iron wire from China embodies the pinnacle of expertise, capability, and trust in the field of construction and industrial materials. For industries contentious about quality and resilience, selecting this product assures a solution grounded in tested performance and reinforced by continuous innovation. It is not merely a purchase but an investment towards efficiency and longevity in varied applications.

Latest news

-

Glass Food Storage Jar with Screw Wooden Lid - Anping County Puersen | Heat Resistance, BPA Free

NewsAug.16,2025

-

High Borosilicate Glass Food Storage Jar with Wooden Screw Lid|Anping County Puersen Hardware Wire Mesh Products Co., Ltd

NewsAug.16,2025

-

Welded Wire Mesh for Industry Factory - Durable & Strong

NewsAug.16,2025

-

Glass Jar with Wooden Screw Lid - Anping County Puersen Hardware Wire Mesh Products Co.,Ltd|Durable, Eco-Friendly Food Storage

NewsAug.15,2025

-

Chain Link Fence - Anping County Puersen | Durable, Versatile Fencing

NewsAug.15,2025

-

Chain Link Fence-Galvanized Steel Fence Factory|Durable Security&Wire Mesh

NewsAug.15,2025