Nov . 11, 2024 09:18 Back to list

china hard drawn steel wire

The Importance of Hard Drawn Steel Wire in Modern Industry

Hard drawn steel wire is an essential material in various industrial applications, valued for its strength, durability, and versatility. This type of wire is produced through a process that involves drawing steel through dies to reduce its diameter while increasing its tensile strength. The resulting product is commonly utilized in construction, manufacturing, and many other sectors. This article will explore the characteristics, manufacturing process, applications, and significance of hard drawn steel wire, particularly in the context of China’s growing industrial landscape.

Characteristics of Hard Drawn Steel Wire

One of the defining features of hard drawn steel wire is its outstanding tensile strength. The drawing process not only reduces the diameter of the wire but also aligns the steel molecules, providing enhanced mechanical properties. This transformation makes the wire less prone to deformation and gives it the ability to withstand substantial loads. Additionally, hard drawn steel wires exhibit a high degree of fatigue resistance, making them suitable for use in products that undergo repeated stress or movement.

Hard drawn steel wires come in various diameters and grades, accommodating the specific requirements of different applications. Whether used in the production of springs, cables, or mesh, the material can be engineered to meet specific tensile strength specifications, corrosion resistance, and other factors crucial for performance.

Manufacturing Process

The manufacturing of hard drawn steel wire typically starts with high-quality steel rods. The rods undergo a series of processes, including heating, pickling, and drawing. During the heating process, the rods are heated to improve their ductility. The pickling step involves cleaning the rods with acid to remove oxides and impurities, ensuring a consistent surface quality. Finally, through a progressive series of dies, the steel is drawn to the desired diameter.

The drawing process is central to the wire's performance. Multiple passes through successively smaller dies generate significant elongation and strain hardening. The final product is not only strong but also possesses a smooth and uniform surface finish, which is important for many applications. After drawing, the wire may undergo additional processes such as annealing – a heat treatment that helps to relieve stresses and enhance ductility.

Applications of Hard Drawn Steel Wire

china hard drawn steel wire

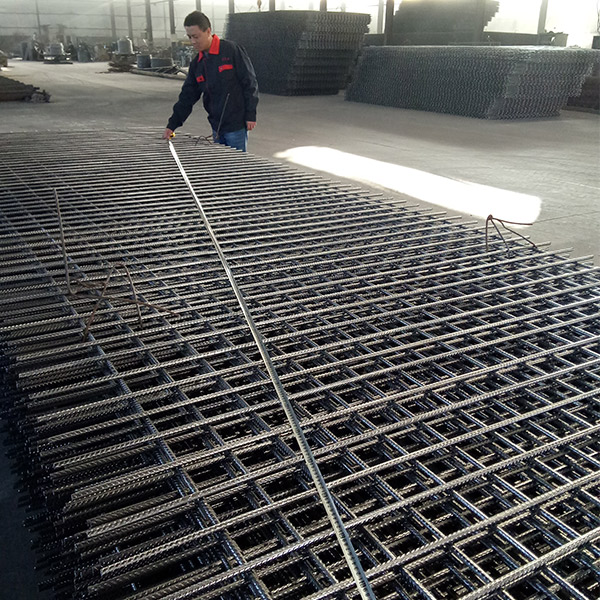

Due to its favorable properties, hard drawn steel wire finds application in a myriad of industries. In construction, it is often used to reinforce concrete structures, where high tensile strength is essential. The wire is incorporated into various types of concrete products, including pre-stressed beams and wire mesh, contributing to the structural integrity of buildings and infrastructure.

In manufacturing, hard drawn steel wire serves as a key component in the production of springs, fasteners, and wire ropes. Its resistance to bending and deformation makes it ideal for applications in automotive and aerospace industries, where reliability and safety are paramount.

Additionally, the agricultural sector utilizes hard drawn steel wire in products like fencing and baling wire. The durability and strength of the wire ensure that it can withstand harsh outdoor conditions while maintaining functionality.

Significance in China’s Industrial Landscape

China has rapidly developed into one of the largest producers and consumers of hard drawn steel wire globally. The country’s extensive construction projects and robust manufacturing sector drive the demand for high-quality steel wire. Chinese manufacturers have invested in advanced technologies and methodologies to produce hard drawn steel wire that meets international standards. This not only enhances the local industrial capability but also positions China as a key player in the global steel market.

The increasing emphasis on infrastructure development and urbanization in China ensures sustained growth in demand for hard drawn steel wire. Furthermore, the ongoing technological advancements in steel production will likely lead to innovations in wire quality and application, fulfilling the evolving needs of the industry.

Conclusion

Hard drawn steel wire is an indispensable material in modern industry, with its high tensile strength and versatility making it suitable for various applications. As the landscape of global manufacturing continues to evolve, hard drawn steel wire will play a critical role in supporting infrastructure and technology. China's position as a leading manufacturer and consumer underscores the material's significance in bridging the gap between traditional industries and the future of engineering innovation.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025