Dec . 05, 2024 08:39 Back to list

China Cold Ribbed Steel Bars for Reinforcement in Construction and Mesh Applications

The Importance of Cold Ribbed Steel Bars for Reinforcing Mesh in China

In the contemporary construction landscape, the use of advanced materials is essential for ensuring the longevity and resilience of infrastructures. One such material gaining prominence in China is the cold ribbed steel bar, pivotal in the manufacturing of reinforcing mesh. This article explores the significance, manufacturing process, and advantages of cold ribbed steel bars in reinforcing mesh applications.

Understanding Cold Ribbed Steel Bars

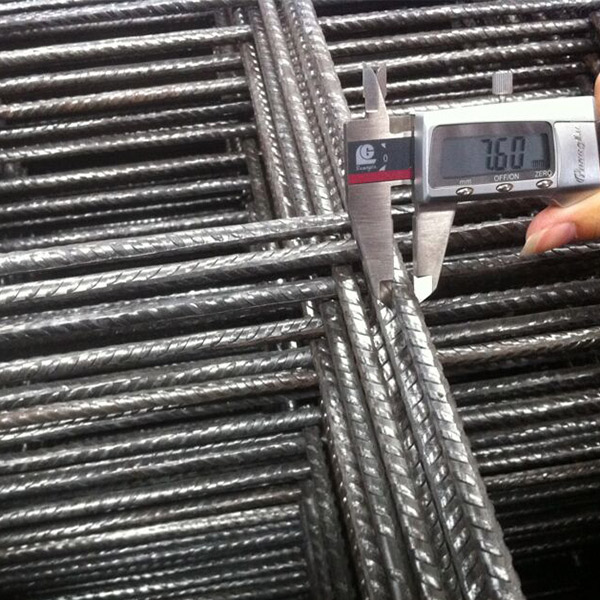

Cold ribbed steel bars, often referred to as ribbed or deformed bars, are produced through a unique process that enhances their strength and bonding capacity with concrete. Unlike traditional smooth steel bars, cold ribbed steel bars feature ribs or deformations along their surface, which significantly improves their ability to adhere to concrete, allowing for structural integrity and reducing the risk of slippage. This property makes them ideal for various construction applications, particularly in building foundations, bridges, and high-rise buildings.

The Manufacturing Process

The production of cold ribbed steel bars involves several stages. Initially, high-quality steel billets are heated and rolled into long bars. These bars then undergo a cold working process, where they are subjected to mechanical deformation without heating. This process enhances their yield strength and tensile strength while maintaining ductility, ensuring that the bars can withstand significant forces during construction and throughout their service life.

Following the cold working process, the bars are subjected to surface treatment to enhance their corrosion resistance, which is crucial in the humid and variable climates often found in China. The final product is subjected to rigorous quality control measures to ensure compliance with national and international standards, making cold ribbed steel bars a trusted choice for engineers and architects alike.

Advantages of Cold Ribbed Steel Bars in Reinforcing Mesh

china cold ribbed steel bar for reinforcing mesh

1. Enhanced Bonding with Concrete The ribs on cold ribbed steel bars create mechanical interlocking with concrete, thus ensuring a strong bond that enhances the overall stability of the structure. This property is especially important in seismic regions where buildings must withstand significant lateral forces.

2. Higher Strength and Ductility Cold ribbed bars have superior tensile strength compared to smooth bars, allowing for lighter and more efficient reinforcement designs. They also exhibit good ductility, which prevents sudden failure and allows structures to absorb shocks and vibrations effectively.

3. Cost-effectiveness Although the initial cost of cold ribbed steel bars may be slightly higher than that of traditional bars, their increased performance characteristics often lead to cost savings in the long run. The enhanced durability reduces maintenance costs and extends the lifespan of structures.

4. Versatile Applications Cold ribbed steel bars are suitable for a wide range of applications, from residential buildings to large infrastructure projects. Their adaptability makes them a preferred choice in the construction industry.

5. Sustainability The production process of cold ribbed steel bars can be relatively energy-efficient, especially if recycled steel is used as a raw material. This contributes to the sustainability efforts within the construction sector.

Conclusion

As China continues to experience rapid urbanization and infrastructure development, the demand for high-quality construction materials is ever-increasing. Cold ribbed steel bars for reinforcing mesh represent a progressive solution that meets the high-performance standards necessary for modern construction. Their enhanced bonding properties, strength, and versatility make them indispensable to engineers and designers striving for durability and safety in their projects. As the construction landscape evolves, the importance of materials like cold ribbed steel bars will only continue to grow, shaping the foundations of tomorrow’s structures in China and beyond.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025