Nov . 08, 2024 10:06 Back to list

Cold Drawn Spring Wire Manufacturing and Applications in China

The Evolution and Significance of Cold Drawn Spring Wire in China

Cold drawn spring wire has emerged as a vital component in various industrial applications, ranging from automotive and aerospace engineering to consumer goods manufacturing. In China, the production of cold drawn spring wire has witnessed significant advancements and has become an essential part of the modern materials landscape. This article delves into the characteristics, manufacturing processes, applications, and the future of cold drawn spring wire in the Chinese market.

Understanding Cold Drawn Spring Wire

Cold drawn spring wire is a type of wire that undergoes a specific manufacturing process to enhance its mechanical properties. The wire is drawn through a die at room temperature, which reduces its diameter and increases its tensile strength. This process improves the wire's uniformity, surface finish, and overall durability. As a result, cold drawn spring wire can withstand higher stress and strain, making it ideal for applications that require high performance under rigorous conditions.

Manufacturing Process

The manufacturing process of cold drawn spring wire involves several key steps. Initially, high-quality steel or alloy rods are selected as the raw material. These rods are often sourced from reputable steel manufacturers to ensure consistency in quality. The rods are then subjected to a series of drawing processes, where they are pulled through progressively smaller dies. This not only reduces the diameter of the wire but also aligns the crystalline structure of the metal, enhancing its strength.

After the drawing process, the wire typically undergoes heat treatment, which may include processes such as annealing or quenching and tempering. These treatments further refine the material properties, ensuring that the wire can meet specific industry standards. Finally, the wire is subjected to rigorous quality control tests, including tensile testing and surface inspections, to ensure that it meets the required specifications.

Applications of Cold Drawn Spring Wire

Cold drawn spring wire is utilized in a vast array of applications, particularly where reliability and performance are paramount

. Some of its primary uses includechina cold drawn spring wire

1. Automotive Industry Spring wires are integral components in vehicle suspension systems, enabling shock absorption and providing stability. They are also vital in manufacturing various automotive parts, including valves and fasteners.

2. Aerospace Engineering The aerospace sector relies on high-strength cold drawn spring wires for producing critical components that must endure extreme conditions, such as fluctuating temperatures and pressures.

3. Consumer Goods Cold drawn spring wire is commonly used in various consumer products, ranging from furniture to appliances. Its strength and flexibility make it suitable for applications in mechanisms such as hinges and springs.

4. Construction In the construction industry, cold drawn spring wires are utilized in reinforcing materials and systems, contributing to the overall safety and durability of structures.

The Chinese Market and Future Prospects

China's cold drawn spring wire industry has seen tremendous growth, fueled by both domestic demand and global exports. The country has invested significantly in modernization and technology to enhance production capabilities and efficiency. With a growing emphasis on quality and sustainability, many Chinese manufacturers are now adopting advanced technologies to improve their processes and reduce waste.

The future prospects for cold drawn spring wire in China appear bright. With the continued growth of the automotive and aerospace industries as well as advancements in smart manufacturing, the demand for high-quality spring wire is expected to increase. Additionally, as China moves towards greener production methods, the emphasis on sustainable materials and practices will likely influence the cold drawn spring wire industry positively.

Conclusion

In conclusion, cold drawn spring wire is a critical material that underpins numerous industries, showcasing its versatility and strength. With China's robust manufacturing capabilities and focus on innovation, the country is poised to remain a key player in the global cold drawn spring wire market. As industries evolve and demand for quality materials rises, cold drawn spring wire will undoubtedly play an increasingly important role in shaping the future of manufacturing and engineering in China and beyond.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

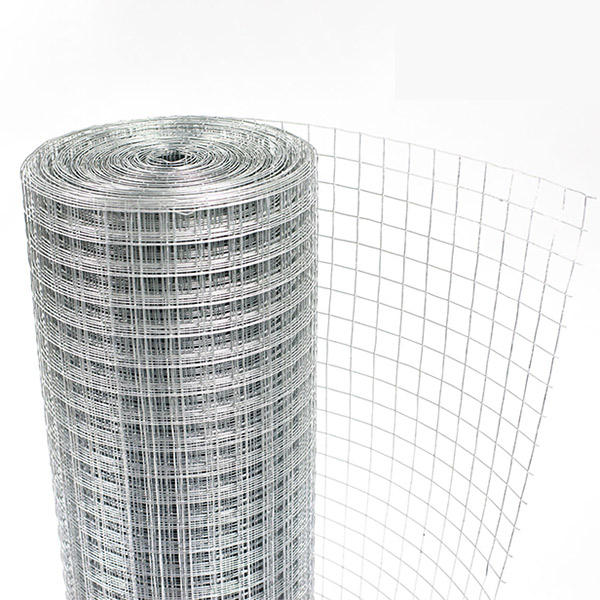

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025