Dec . 12, 2024 10:44 Back to list

china binding iron wire

The Role of China in the Global Binding Iron Wire Market

In recent years, the role of China in the global iron wire industry has increasingly been a focal point of discussion among manufacturers, suppliers, and consumers. Among the various products associated with this industry, binding iron wire has gained particular importance due to its versatility and application in numerous sectors, including construction, agriculture, and manufacturing. This article explores the significance of binding iron wire, the production capabilities of China, and the trends shaping the market.

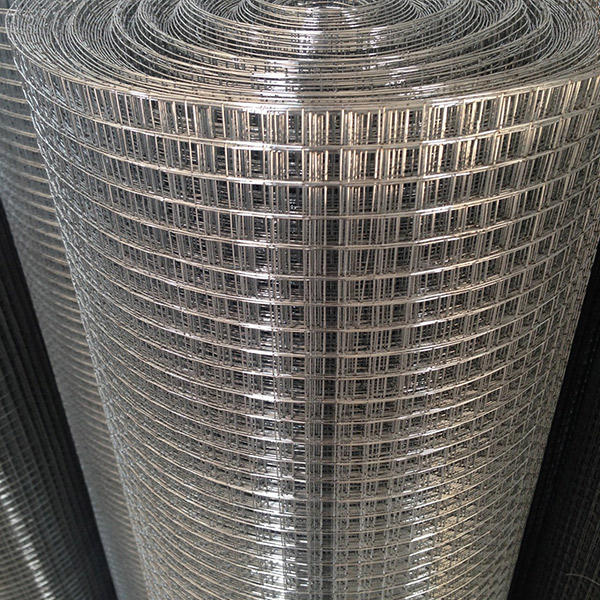

Binding iron wire, typically made from low-carbon steel, is characterized by its ductility and strength. It is primarily used for tying and securing materials, making it vital for reinforcing concrete structures, agricultural operations, and even crafting decorative items. The demand for binding wires is continually rising, driven by urbanization, infrastructure development, and the expanding agricultural industry across the globe.

The Role of China in the Global Binding Iron Wire Market

The export of binding iron wire from China has witnessed remarkable growth over the past decade. Countries in Asia, Europe, the Americas, and Africa are increasingly sourcing wiring products from Chinese suppliers. This international demand not only reflects the quality of Chinese manufacturing but also highlights its capacity to adapt to different market needs. With a variety of grades and specifications available, Chinese manufacturers can cater to diverse applications, from heavy-duty construction to lightweight agricultural uses.

china binding iron wire

However, the Chinese iron wire industry is not without its challenges. Regulatory issues, environmental concerns, and trade tensions have created obstacles for manufacturers. For instance, stricter environmental regulations in China have compelled factories to adopt more sustainable practices, which can increase production costs. Additionally, trade tariffs imposed by various countries can hinder the export of Chinese goods, causing fluctuations in market prices and availability.

To navigate these challenges, Chinese manufacturers are investing in innovation and sustainability. Many are striving to implement advanced manufacturing techniques, such as automated production lines and eco-friendly processes. These efforts not only help improve the quality of binding iron wire but also address environmental concerns associated with the industry.

Looking forward, the global binding iron wire market is expected to evolve significantly. With the ongoing trends of green building practices and sustainable agriculture, there will likely be an increased demand for eco-friendly binding solutions. Chinese manufacturers are already exploring options to produce binding wire from recycled materials, which aligns with global sustainability goals. Additionally, as international trade dynamics shift, manufacturers will need to remain agile and responsive to changing market demands.

In conclusion, binding iron wire plays a crucial role in various sectors worldwide, and China's position in this market is paramount. With its robust production capabilities, competitive pricing, and adaptability, China continues to shape the future of the global binding iron wire industry. As challenges in regulation and trade emerge, the industry will need to focus on innovation and sustainability to maintain its leading role. The concerted efforts of Chinese manufacturers to innovate and enhance their product offerings could very well set the tone for the future, ensuring that the binding iron wire market not only survives but thrives in the evolving global landscape.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025