Nov . 11, 2024 07:51 Back to list

china 6mm-12mm wire gauge cold drawn wire

Understanding China's 6mm-12mm Wire Gauge Cold Drawn Wire

In recent years, the manufacturing sector in China has gained significant recognition for its production of wire products, particularly cold drawn wire. One particular category of this product is the 6mm-12mm wire gauge cold drawn wire, which has a wide array of applications across various industries. This article will explore the characteristics, manufacturing processes, and applications of this essential product.

What is Cold Drawn Wire?

Cold drawn wire refers to wire that is produced using a process known as cold drawing. This process involves pulling the wire through a die to reduce its diameter while simultaneously increasing its tensile strength. The wire is typically drawn at room temperature, which allows for precise control over the dimensions and properties of the finished product. This method enhances the hardness and tensile strength of the wire, making it suitable for demanding applications.

Characteristics of 6mm-12mm Wire Gauge Cold Drawn Wire

The 6mm-12mm wire gauge cold drawn wire possesses several noteworthy characteristics. Firstly, its diameter ranges from 6mm to 12mm, making it versatile for a variety of uses. The wire is typically produced from high-quality raw materials such as low carbon steel, stainless steel, or other alloys, which contribute to its durability and strength.

Another important characteristic is its smooth finish and consistent diameter. The cold drawing process ensures that the wire maintains uniformity, which is crucial for applications where precision is necessary. Additionally, cold drawn wire exhibits excellent resistance to corrosion, depending on the material used, which further extends its applications in industries that require reliability under harsh environmental conditions.

Manufacturing Process

china 6mm-12mm wire gauge cold drawn wire

The manufacturing process of cold drawn wire involves several steps, starting with the selection of raw materials. Once the appropriate materials are chosen, they undergo annealing to soften the metal and facilitate the drawing process. After annealing, the wire is passed through a series of drawing dies, reducing its diameter while increasing its length and strength.

This system of continuous drawing enables manufacturers to produce long lengths of wire, which can then be cut to the desired specifications. After drawing, the wire may go through additional processes such as heat treatment, coating, or galvanizing to enhance its properties further. Quality assurance is a crucial aspect throughout the production, with various tests conducted to check for tensile strength, diameter accuracy, and surface finish.

Applications of 6mm-12mm Cold Drawn Wire

The applications of 6mm-12mm wire gauge cold drawn wire are extensive. In the construction industry, this wire is often used for tie rods, reinforcement bars, and other structural components that demand high strength and durability. Its robustness makes it suitable for use in bridges, buildings, and various infrastructure projects.

In the automotive sector, cold drawn wire is used in manufacturing parts such as springs, cables, and various components that require excellent tensile strength. Additionally, industries such as electronics, aerospace, and machinery benefit from the use of this wire in producing various components and assemblies.

Furthermore, the wire is also prevalent in the creation of wire mesh, fencing, and other security products, where both strength and flexibility are essential.

Conclusion

China's 6mm-12mm wire gauge cold drawn wire plays a vital role in various industries due to its superior properties and versatility. The cold drawing process enhances its durability and performance, making it a preferred choice for demanding applications. As industries continue to advance, the demand for high-quality cold drawn wire is expected to grow, ensuring its importance in the global market. Understanding its characteristics, manufacturing processes, and applications will aid in leveraging this product effectively across different sectors.

-

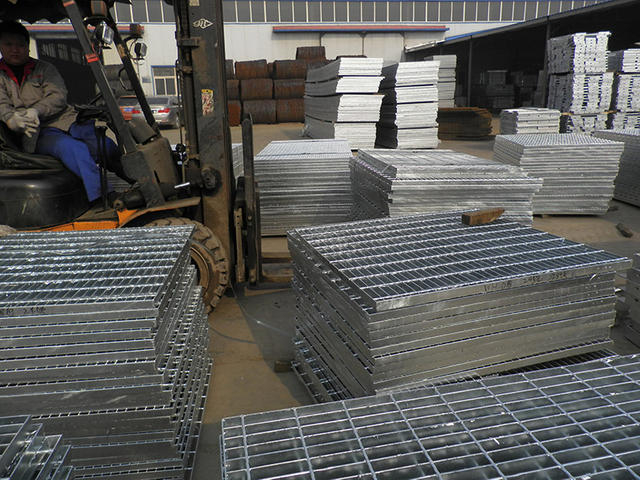

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025