Oct . 10, 2024 23:17 Back to list

china 12 gauge welded wire mesh

The Significance of China’s 2012 Gauge Welded Wire Mesh Industry

In the realm of construction and manufacturing, wire mesh plays a crucial role in providing structural support, safety, and durability. Among the various types of wire mesh available on the market, welded wire mesh has gained considerable traction due to its strength and versatility. Since 2012, China has been a pivotal player in the production and innovation of welded wire mesh, specifically focusing on the 2012 gauge specifications. This article aims to explore the significance of this sector and its impacts on various industries.

Understanding Welded Wire Mesh

Welded wire mesh is constructed from steel wires that are electrically welded together at their intersections, forming a grid-like structure. It is typically available in different gauges, which refer to the wire thickness. The 2012 gauge wire mesh, which utilizes wires that are 2.0 mm (or roughly 12 gauge) in diameter, is particularly popular for its balance between strength and flexibility. This gauge is suitable for a range of applications, from construction to agriculture, owing to its ability to withstand tension while being easy to handle and install.

China’s Role in the Welded Wire Mesh Market

Since 2012, China has emerged as a global leader in the production of welded wire mesh. The country's robust manufacturing infrastructure, combined with its access to low-cost raw materials, enables it to produce high volumes of this essential material at competitive prices. Furthermore, China's continuous investment in modern technology and quality control processes ensures that its products meet international standards, making Chinese welded wire mesh highly sought after in global markets.

The production capacity of Chinese manufacturers has significantly increased over the years, allowing them to cater to both domestic and international demands. Regions such as Anping in Hebei Province have become synonymous with wire mesh manufacturing, featuring a plethora of factories that specialize in various wire mesh types, including the popular 2012 gauge.

Applications of 2012 Gauge Welded Wire Mesh

china 12 gauge welded wire mesh

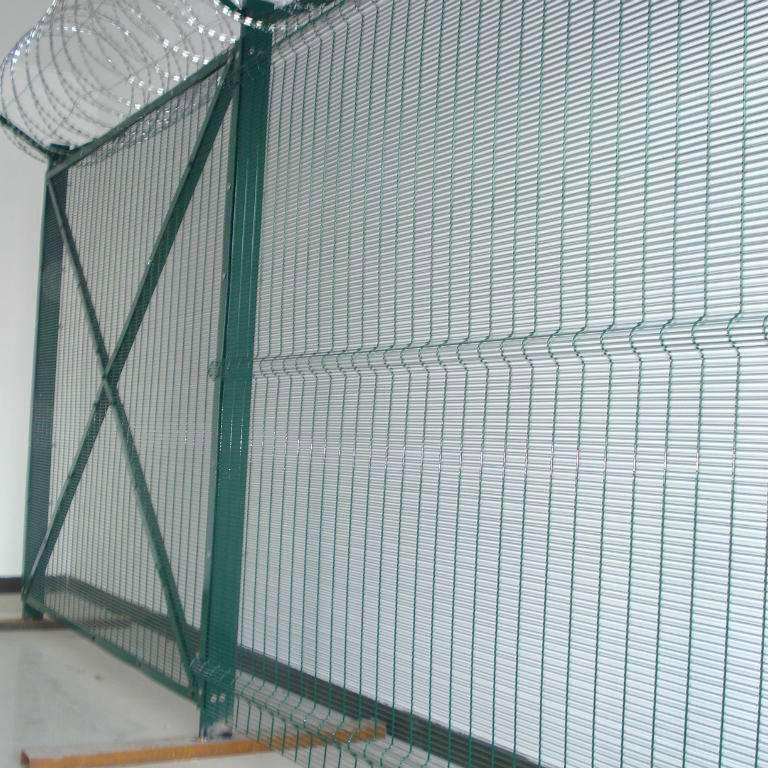

The versatility of 2012 gauge welded wire mesh has led to its adoption in numerous applications. In construction, it is commonly used as reinforcement in concrete, providing added tensile strength. It is also employed in fencing solutions, offering security for both residential and commercial properties. In agricultural settings, welded wire mesh serves as enclosures for livestock and protection for crops, demonstrating its importance in the farming sector.

Moreover, the mesh material functions effectively in industrial settings, where it is utilized for shelving, safety barriers, and machine guards. Its resistance to corrosion and overall durability ensure that it can withstand varying environmental conditions, making it a reliable choice for long-term use.

Environmental Considerations and Future Trends

As environmental awareness rises globally, sustainability has become a focal point in manufacturing practices. In response, Chinese manufacturers of welded wire mesh are adopting eco-friendly production methods and materials. Efforts are being made to reduce energy consumption and minimize waste during the manufacturing process, which not only benefits the environment but also enhances the overall product quality.

In the future, the demand for 2012 gauge welded wire mesh is expected to grow, driven by advancements in construction techniques, urbanization, and a rise in infrastructure projects worldwide. As industries evolve, the continued innovation within the welded wire mesh sector will likely lead to the development of new products, tailored to specific applications and market needs.

Conclusion

In summary, the 2012 gauge welded wire mesh produced in China plays a significant role in various industries and applications. Its affordability, strength, and versatility make it an invaluable material in the construction, agricultural, and industrial sectors. As China continues to lead in this domain, the focus on sustainability and innovation will surely shape the future of the welded wire mesh industry, solidifying its place in the global market.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025