Nov . 13, 2024 23:55 Back to list

chain link wire mesh factories

Chain Link Wire Mesh Factories An Overview

Chain link wire mesh, a versatile fencing solution, is widely used in various applications ranging from residential to commercial and industrial purposes. Its popularity stems from its durability, affordability, and ease of installation. In recent years, the demand for chain link wire mesh has seen substantial growth, leading to the proliferation of factories dedicated to manufacturing this essential material.

Understanding Chain Link Wire Mesh

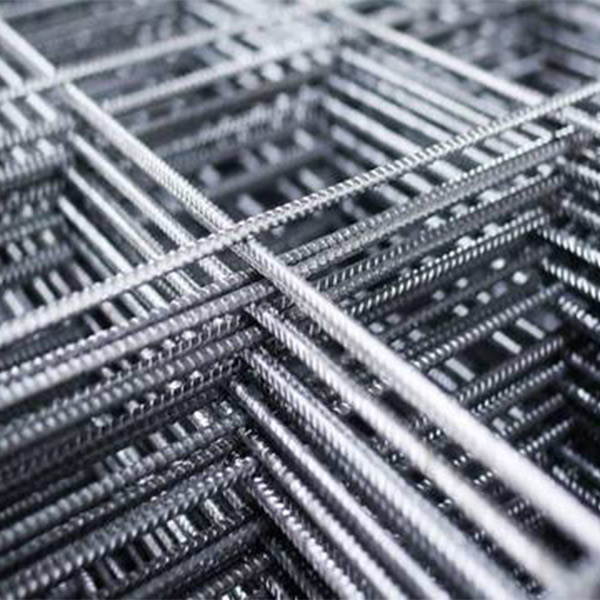

Chain link wire mesh is composed of interwoven steel wires, creating a diamond-shaped pattern that is both sturdy and flexible. The manufacturing process typically involves the weaving of galvanized or vinyl-coated wire, enhancing its resistance to rust and corrosion. These characteristics make it an ideal choice for fencing around sports fields, residential properties, parks, and security enclosures.

The Manufacturing Process

The production of chain link wire mesh follows a series of systematic steps. Firstly, raw materials, primarily steel wire, are sourced. The quality of this wire is critical, as it influences the mesh's overall strength and longevity. Factories often treat the wire through galvanization, a process where a zinc coating is applied to prevent rusting and deterioration.

Once the wire is ready, it undergoes a weaving process. Large machines designed for this purpose twist and interlace the wire to form the characteristic diamond pattern. The width and height of the mesh can be adjusted depending on the intended application. After weaving, the mesh is usually rolled up into manageable sections for shipping and installation.

Quality Control in Factories

Quality control is a vital aspect of manufacturing chain link wire mesh. Factories implement rigorous testing procedures to ensure that the final product meets industry standards. This includes examining the tensile strength of the wire, the uniformity of the mesh pattern, and the consistency of the galvanization process. Quality control ensures that the products are robust and suitable for various environmental conditions, providing customers with a reliable fencing solution.

Technological Advancements

chain link wire mesh factories

Modern chain link wire mesh factories are integrating advanced technologies to improve production efficiency and product quality

. Automated machinery is increasingly prevalent, enabling faster production times while minimizing labor costs. Additionally, factories are adopting computer-aided design (CAD) systems to create customized solutions that cater to specific customer requirements.Furthermore, innovative materials are being explored to enhance the properties of chain link fences. For instance, some manufacturers are experimenting with polymer-coated wires that offer increased durability and resistance to environmental factors. Such advancements are essential in ensuring that chain link wire mesh remains relevant in a rapidly evolving market.

Environmental Considerations

As global awareness of environmental issues grows, chain link wire mesh factories are making strides towards sustainability. Many manufacturers are seeking to reduce their ecological footprint by optimizing energy consumption during production and minimizing waste. Some factories have implemented recycling programs for scrap metal, ensuring that excess materials do not end up in landfills.

Moreover, the materials used in manufacturing chain link mesh can contribute to sustainability. Galvanized steel is often seen as a more sustainable choice compared to other fencing materials, as it is recyclable and has a long lifespan. By promoting the use of such materials, manufacturers are not only catering to market demands but also contributing to environmental conservation efforts.

The Future of Chain Link Wire Mesh Factories

Looking forward, the future of chain link wire mesh factories appears promising. As urbanization continues to rise, so does the need for effective fencing solutions that guarantee security and privacy. Additionally, the advent of smart technologies in manufacturing processes will likely lead to greater efficiency and lower production costs.

Moreover, further research into enhancing the durability and aesthetic appeal of chain link fences could open up new market opportunities. For example, the incorporation of decorative elements and color options could cater to customers looking for more visually appealing fencing solutions without sacrificing functionality.

Conclusion

Chain link wire mesh factories play a crucial role in producing an essential product that meets diverse fencing needs. With advancements in technology, a focus on sustainability, and a commitment to quality control, these factories are well-positioned to thrive in a competitive market. As the demand for versatile and durable fencing solutions continues to grow, the significance of chain link wire mesh manufacturers in various industries will undoubtedly increase, paving the way for innovation and expansion in the years to come.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025