Nov . 13, 2024 12:50 Back to list

brc welded wire mesh factories

An Overview of BRC Welded Wire Mesh Factories

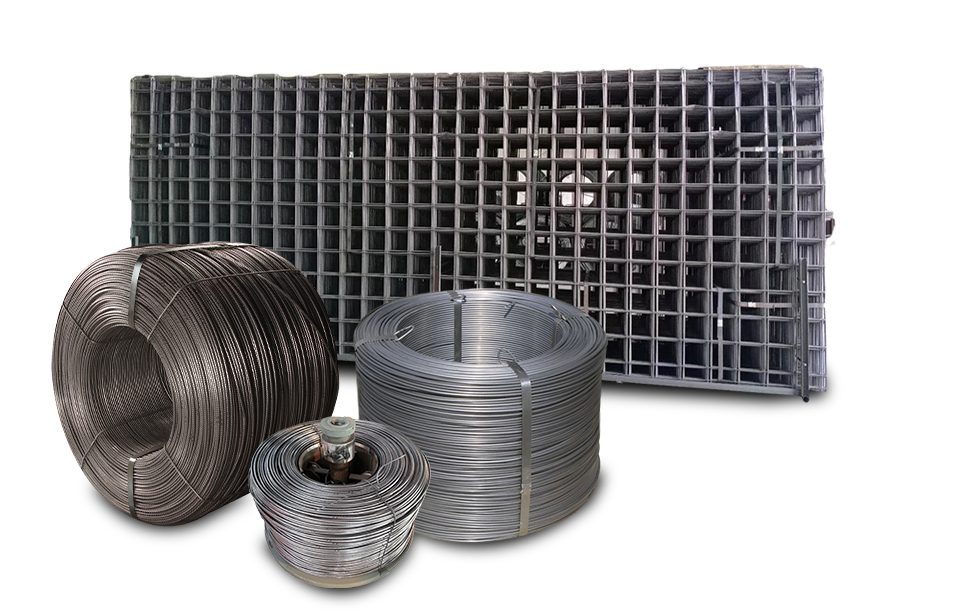

BRC welded wire mesh has become an essential material in various construction industries, lauded for its strength, versatility, and ease of use. These products are manufactured in specialized factories known as BRC welded wire mesh factories, which play a critical role in the construction ecosystem by supplying high-quality welded wire mesh to contractors and builders.

The Manufacturing Process

The manufacturing process in BRC welded wire mesh factories starts with the selection of raw materials, typically high carbon steel wires that are processed to give them the required tensile strength. These wires are then arranged in a grid pattern, which is pivotal to the strength and structural integrity of the final product. The wires are welded at each junction using an automatic welding machine, ensuring that every intersection has a reliable and robust connection.

One of the key advantages of using advanced machinery in the production process is the uniformity and precision it brings. The automated systems ensure that the mesh produced is consistent in quality, which is crucial for construction projects where reliability is paramount. The factories often employ stringent quality control measures, testing the wires for tensile strength and inspecting the welds for any defects.

Applications of BRC Welded Wire Mesh

BRC welded wire mesh is widely used in various applications, including flooring, walls, and reinforcement in concrete structures. Its ability to enhance the structural integrity of concrete makes it a popular choice among engineers and architects. This type of mesh can be found in residential buildings, commercial spaces, and infrastructure projects, such as bridges and tunnels.

The versatility of BRC welded wire mesh allows it to be customized to meet specific project requirements. Factories can produce different sizes and configurations of mesh, catering to diverse application needs. Additionally, the mesh can be galvanized or coated to enhance corrosion resistance, further extending its usability in different environmental conditions.

brc welded wire mesh factories

Advancements in Technology

The landscape of BRC welded wire mesh production has evolved significantly with technological advancements. Modern factories implement Computer Numerical Control (CNC) technology and other automation systems to improve efficiency and reduce production time. This not only ensures high-quality outputs but also leads to cost savings, which can be passed on to customers.

Moreover, the integration of sustainable practices is becoming increasingly prevalent in these factories. Many manufacturers are now using recycled materials and eco-friendly processes, reducing their carbon footprint and contributing to more sustainable construction practices.

The Importance of Quality Assurance

In an industry where safety and durability are paramount, quality assurance in BRC welded wire mesh factories cannot be overstated. Regular inspections and adherence to international standards, such as ISO and ASTM, are crucial to maintaining the integrity of the products. This ensures that the mesh can withstand the rigors of construction and perform reliably over time.

Customers often seek out suppliers who prioritize quality assurance, as it directly impacts the longevity and safety of their construction projects. Long-term partnerships with reputable BRC welded wire mesh factories can also provide clients with peace of mind, knowing they are receiving products that meet rigorous standards.

Conclusion

BRC welded wire mesh factories are integral to the construction supply chain, providing high-quality products that enhance the safety and durability of building structures. With advancements in manufacturing technology and a commitment to quality assurance, these factories ensure that builders and contractors have access to the robust materials they need for their projects. As the construction industry continues to evolve, the role of BRC welded wire mesh factories will undoubtedly grow, supporting the development of infrastructure and housing around the world. Ultimately, their contributions enable the construction of safer, more resilient buildings that stand the test of time.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025